From a technical standpoint, the primary advantages of resistance heating are its exceptional energy efficiency, precise temperature control, and ability to achieve very high temperatures. Because the heat is generated directly within a resistive material by an electric current, nearly 100% of the electrical energy is converted into thermal energy, enabling a level of performance and uniformity that other methods struggle to match.

Resistance heating's core value is its direct and near-perfect conversion of electricity to heat. This allows for unparalleled process control, but this performance is directly tied to electricity consumption, which can be a significant operational cost.

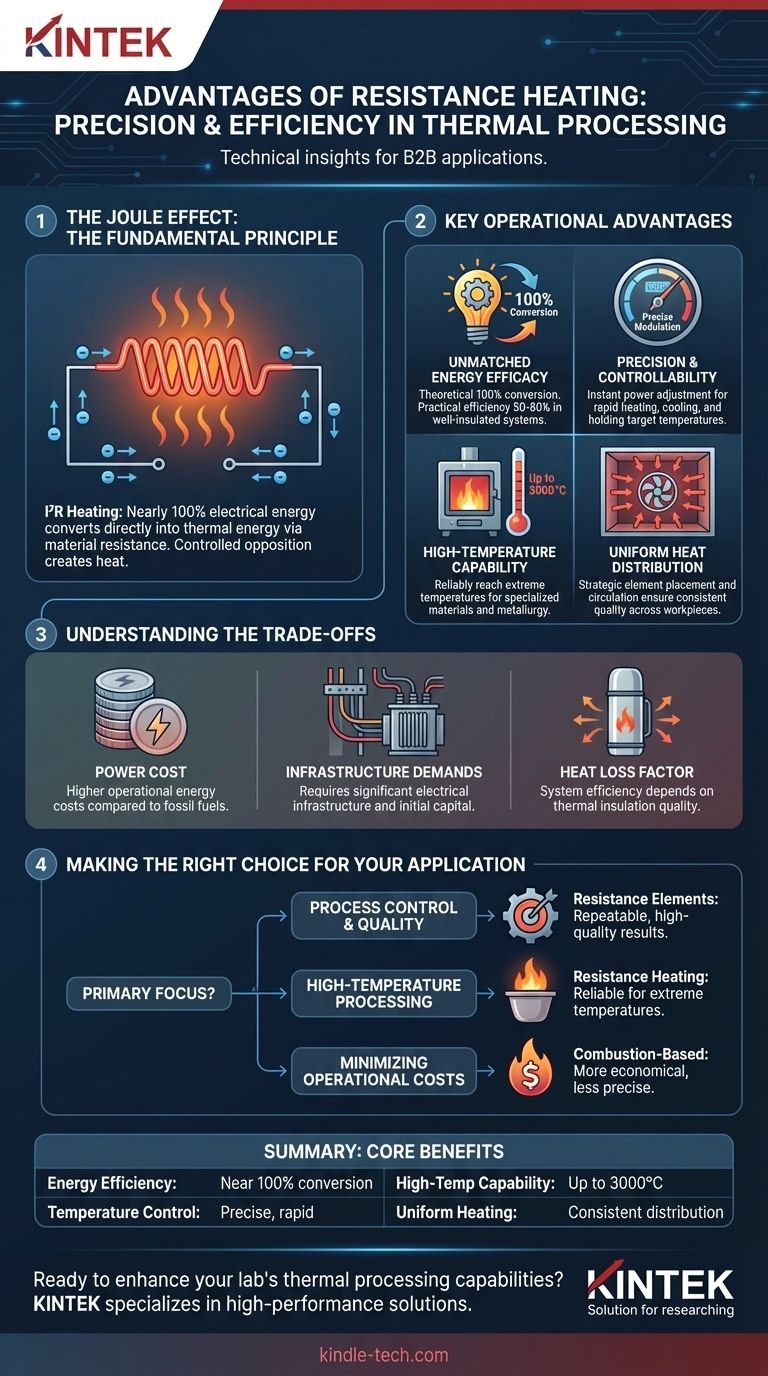

The Fundamental Principle: The Joule Effect

How It Works: Controlled Opposition

Resistance heating operates on a simple and reliable principle known as the Joule effect, or I²R heating. When an electric current (I) flows through a material with electrical resistance (R), the material impedes the flow of electrons.

This "friction" at the atomic level causes the electrons to transfer their energy to the material's atoms, which then vibrate more rapidly. This increased atomic vibration manifests as heat.

The Material Dictates Performance

The effectiveness and temperature range of a resistance heater are determined by the heating element material. These are typically specialized metals or ceramics designed to have high resistance and withstand extreme temperatures without degrading.

Key Operational Advantages

Unmatched Energy Efficacy

The single greatest advantage of resistance heating is its efficacy. In theory, 100% of the electricity supplied is converted into heat.

Unlike combustion, where a significant portion of energy is lost through exhaust gases, electric resistance heating generates heat directly where it is needed. This leads to very high practical thermal efficiencies, often between 50% and 80% in well-designed furnaces.

Precision and Controllability

Electrical current can be modulated with extreme precision. This gives resistance heating systems superior temperature control.

Power can be adjusted instantly, allowing for rapid heating, cooling, and the ability to hold a target temperature with very little deviation. This is critical for processes that demand a specific thermal profile.

High-Temperature Capability

Specialized resistance heating elements can operate at incredibly high temperatures. Certain furnace designs can reliably reach up to 3000°C.

This makes it an essential technology for demanding applications in metallurgy, materials science, and advanced manufacturing that are beyond the reach of conventional combustion.

Uniform Heat Distribution

By strategically placing heating elements around the walls of a chamber or workpiece, it is possible to achieve highly uniform heating.

For even greater uniformity, the furnace atmosphere can be circulated with fans, ensuring that all parts of the workpiece reach the same temperature. This is vital for consistent quality in heat treatment and curing processes.

Understanding the Trade-offs

The Cost of Power

While it is highly efficient at converting electricity to heat, electricity is often a more expensive energy source than natural gas or other fossil fuels.

The primary drawback of resistance heating is its high power consumption, which can lead to significant operational costs, especially in large-scale industrial applications.

Infrastructure Demands

Implementing a high-power resistance heating system is not a simple plug-and-play operation. It often requires significant electrical infrastructure, including heavy-gauge wiring, dedicated circuits, and transformers, which can add to the initial capital expense.

Heat Loss Is Still a Factor

While the energy conversion is 100% efficient, the overall system is not. Heat will always be lost to the surrounding environment through the furnace walls.

The practical efficiency of 50-80% is highly dependent on the quality of the system's thermal insulation. Poor insulation will negate the benefits of efficient heat generation.

Making the Right Choice for Your Application

Your decision should hinge on balancing the need for control and quality against operational energy costs. The ideal choice depends entirely on your process requirements.

- If your primary focus is process control and quality: The precise temperature regulation and uniform heat distribution of resistance elements are your best choice for repeatable, high-quality results.

- If your primary focus is high-temperature processing: Resistance heating is one of the few technologies capable of reliably and cleanly reaching the extreme temperatures required for specialized materials.

- If your primary focus is minimizing operational energy costs: The high electrical power draw may make combustion-based systems a more economical alternative, provided you can tolerate less precise temperature control.

Ultimately, understanding these core principles and trade-offs empowers you to select the optimal heating technology for your specific engineering goals.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Energy Efficiency | Near 100% conversion of electricity to heat |

| Temperature Control | Precise, rapid heating and cooling |

| High-Temperature Capability | Can reach up to 3000°C |

| Uniform Heating | Consistent heat distribution for quality results |

Ready to enhance your lab's thermal processing capabilities?

KINTEK specializes in high-performance lab equipment, including advanced resistance heating furnaces. Our solutions deliver the precise temperature control, uniformity, and high-temperature performance your research or production demands.

Contact our experts today to discuss how we can provide the right heating solution for your specific laboratory needs.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why use a tube furnace? Achieve Superior Temperature Uniformity and Atmosphere Control

- What tube is used for tubular furnace? Choose the Right Material for Temperature & Atmosphere

- Why is an Alumina Ceramic Tube Support Necessary for 1100°C Experiments? Ensure Data Accuracy and Chemical Inertness

- How do you clean a tube furnace tube? A Step-by-Step Guide to Safe and Effective Cleaning

- What is the primary advantage of using a tube furnace? Achieve Superior Temperature and Atmosphere Control