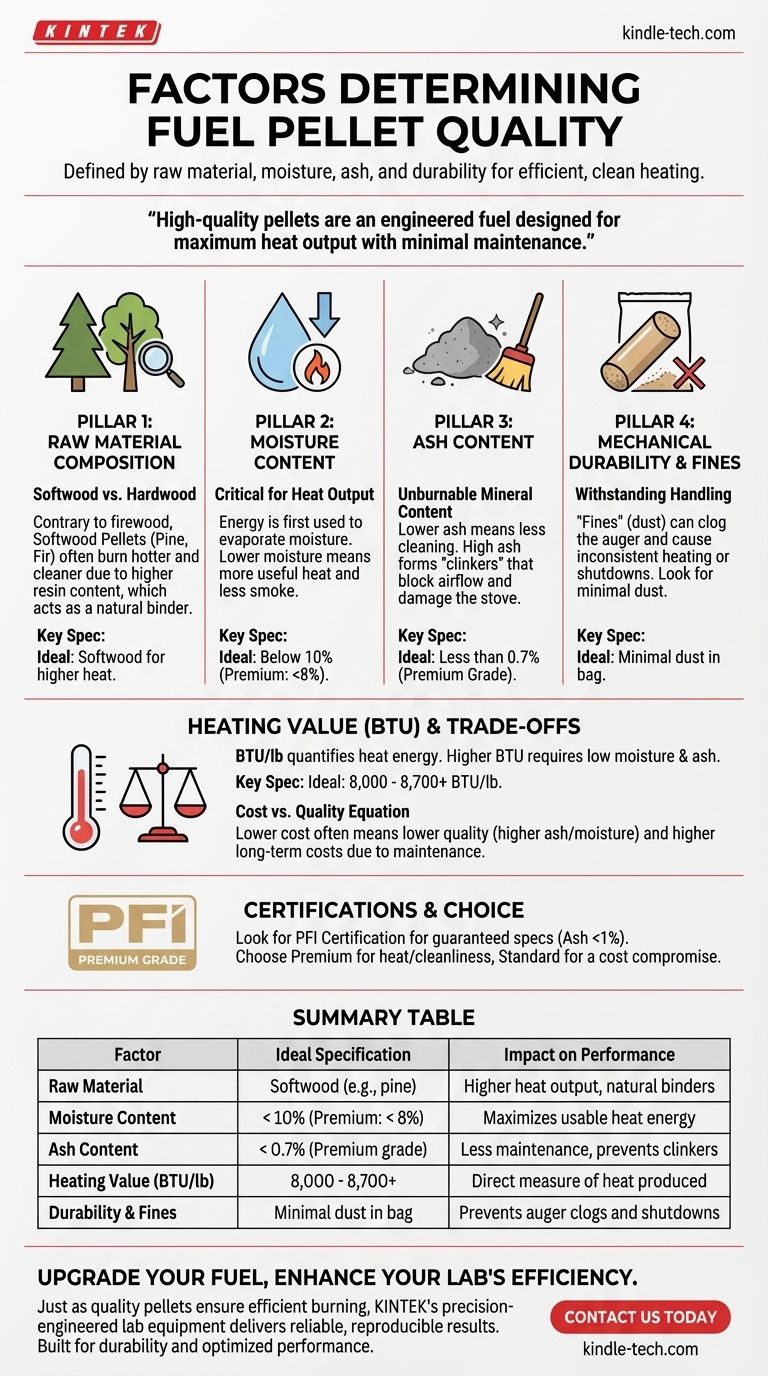

The quality of a fuel pellet is defined by four primary characteristics. These are the raw material used, its moisture content, its ash content, and its physical durability. Together, these factors dictate how much heat the pellet will produce, how cleanly it will burn, and how well it will perform in your stove's auger system.

High-quality pellets are not simply compressed sawdust; they are an engineered fuel designed for maximum heat output with minimal maintenance. Understanding the key quality indicators allows you to move beyond price and select a fuel that ensures the efficient and reliable operation of your heating appliance.

The Core Pillars of Pellet Quality

The performance of your pellet stove or boiler is directly tied to the fuel you use. Inferior pellets can lead to lower heat output, frequent cleaning, and even damage to mechanical components over time.

Raw Material Composition

The type of wood used is the foundation of the pellet. The two main categories are softwood (like pine or fir) and hardwood (like oak or maple).

Contrary to firewood logic, softwood pellets often burn hotter and cleaner than hardwood pellets. This is due to their higher resin content, which has a high energy value and acts as a natural binder during compression.

Moisture Content

This is one of the most critical factors for heat output. Energy in the pellet must first be used to boil off any internal moisture before it can be converted into useful heat for your home.

An ideal pellet should have a moisture content below 10%, with premium pellets often achieving levels below 8%. Higher moisture means less heat and more smoke.

Ash Content

Ash is the unburnable mineral content left behind after combustion. A lower ash content is always better, as it directly translates to less maintenance and cleaning.

High levels of ash can form hard, glassy deposits called "clinkers" in the stove's burn pot, which block airflow and can shut down the appliance. Premium-grade pellets typically have an ash content of less than 0.7%.

Heating Value (BTU)

The heating value, measured in British Thermal Units (BTU), quantifies the amount of energy a pound of pellets can produce. A higher BTU rating means more heat from each bag.

This value is directly influenced by the other factors. Low moisture and low ash content are prerequisites for a high BTU rating, which is typically in the range of 8,000 to 8,700 BTU per pound for high-quality pellets.

Mechanical Durability & Fines

This refers to the pellet's ability to withstand transportation and handling without crumbling into dust. The resulting dust, known as "fines," can cause significant problems.

Excessive fines can clog the auger that feeds pellets to the burn pot, leading to inconsistent heating or stove shutdowns. Look for bags with minimal dust at the bottom, indicating good durability.

Understanding the Trade-offs and Certifications

Choosing pellets isn't just about finding the "best" numbers; it's about finding the right balance for your needs and understanding what to look for on the bag.

The Cost vs. Quality Equation

Lower-cost pellets are almost always of lower quality. They may contain bark, have higher moisture, or produce more ash.

While the initial savings may be appealing, they often result in higher long-term costs due to increased stove maintenance, more frequent cleaning, and lower overall heating efficiency.

The Role of Binders

Some pellets, particularly those made from materials with less natural resin, may use binding agents to improve durability.

High-quality pellets typically use natural binders like starch. Be cautious of pellets that don't specify their binder, as some may contain chemicals you do not want to burn indoors.

Look for Quality Certifications

The most reliable way to ensure quality is to look for an industry certification mark on the bag, such as from the Pellet Fuels Institute (PFI).

The PFI program sets standards for "Premium" and "Standard" grades. A "Premium" certification guarantees an ash content of less than 1%, ensuring a cleaner and more efficient burn.

How to Choose the Right Pellets for Your Stove

Your choice should align directly with your primary goal, whether it's maximizing heat, minimizing cost, or protecting your equipment.

- If your primary focus is maximum heat output and minimal cleaning: Choose a PFI-certified "Premium" grade softwood pellet with an ash content explicitly listed below 0.7%.

- If your primary focus is balancing cost and performance: A PFI-certified "Standard" grade pellet can be a good compromise, but be prepared for slightly more frequent burn pot cleaning.

- If your primary focus is avoiding equipment issues: Always check the bottom of the bag for fines. A small amount is normal, but if you see more than a half-cup of dust, it indicates poor durability that could clog your auger.

Ultimately, investing in high-quality pellets is an investment in the efficiency and longevity of your heating appliance.

Summary Table:

| Factor | Ideal Specification | Impact on Performance |

|---|---|---|

| Raw Material | Softwood (e.g., pine) | Higher heat output, natural binders |

| Moisture Content | < 10% (premium: < 8%) | Maximizes usable heat energy |

| Ash Content | < 0.7% (Premium grade) | Less maintenance, prevents clinkers |

| Heating Value (BTU/lb) | 8,000 - 8,700+ | Direct measure of heat produced |

| Durability & Fines | Minimal dust in bag | Prevents auger clogs and stove shutdowns |

Upgrade Your Fuel, Enhance Your Lab's Efficiency

Just as high-quality pellets are essential for a clean, efficient burn, precision-engineered lab equipment is critical for reliable, reproducible results. KINTEK specializes in high-performance laboratory equipment and consumables, serving the exacting needs of research and quality control labs.

Our products are designed with the same attention to detail that defines a premium fuel pellet: built for durability, optimized for performance, and certified for quality. Whether you need precise temperature control, robust materials, or consistent outcomes, KINTEK delivers the reliability your lab depends on.

Contact us today to discuss how our solutions can bring superior efficiency and longevity to your laboratory operations.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Single Punch Manual Tablet Press Machine TDP Tablet Punching Machine

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

People Also Ask

- What is the significance of using a fine sieving system for catalyst particles? Optimize Size for Maximum Reactivity

- Why use a vibratory sieve shaker for PET powder? Achieve Precise Particle Size Control for Chemical Research

- What are the disadvantages of sieve machine? Key Limitations in Particle Size Analysis

- Why is a precision vibratory sieving system important for Pt/Pd alloy analysis? Ensure Data Integrity & XRD Accuracy

- Why is a laboratory electromagnetic vibratory sieve shaker used? Optimize Walnut Shell Chemical Pretreatment