In short, laboratory freeze dryers excel at preserving sensitive materials. They do this by removing water without the damaging effects of heat, which extends shelf life, maintains the original structure and biological activity of the sample, and ensures the product can be easily rehydrated for later use.

The fundamental advantage of freeze drying over all other dehydration methods is its gentle nature. By freezing a sample and then turning the ice directly into vapor under a vacuum—a process called sublimation—it removes moisture while preserving the delicate physical and chemical structure of the original material.

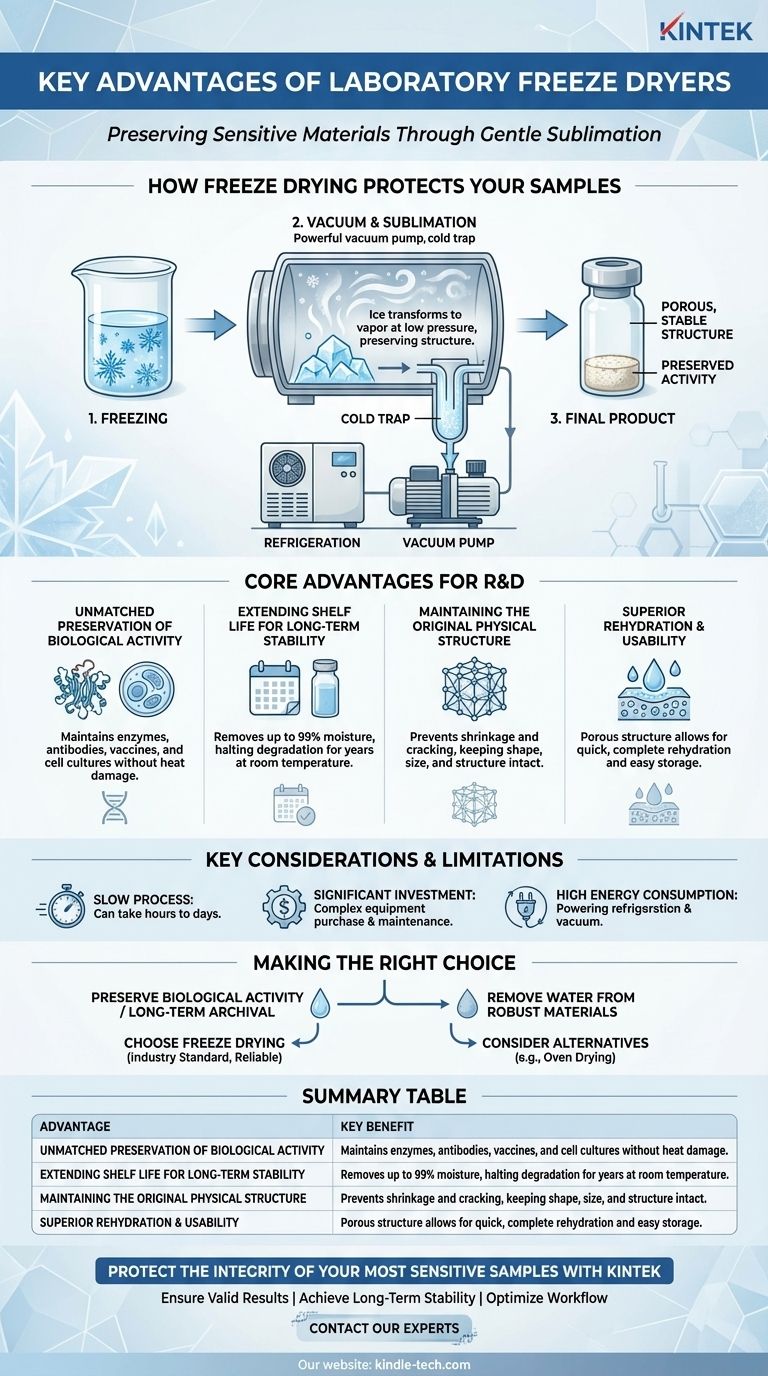

How Freeze Drying Protects Your Samples

The unique benefits of a laboratory freeze dryer, or lyophilizer, stem directly from its underlying scientific principle. Unlike simple heating or evaporation, it works in a way that minimizes damage to sensitive substances.

The Principle of Sublimation

A freeze dryer operates by first freezing a liquid sample to a very low temperature, turning all the water within it into solid ice.

Next, a powerful vacuum pump dramatically lowers the pressure inside the chamber. Under this low pressure, the ice is encouraged to transition directly from a solid to a gas (vapor) without ever passing through a liquid phase. This process is known as sublimation.

The Role of Core Components

This process is managed by two key systems. The refrigeration unit achieves the initial deep freeze, while the vacuum pump creates the low-pressure environment necessary for sublimation. A cold trap then captures the water vapor, preventing it from damaging the vacuum pump.

The Core Advantages for Research and Development

By removing water through sublimation instead of heat-driven evaporation, freeze drying delivers several critical advantages that are essential for scientific and pharmaceutical applications.

Unmatched Preservation of Biological Activity

For materials like enzymes, antibodies, vaccines, and cell cultures, heat is destructive. It can denature proteins and render the sample useless.

Freeze drying bypasses this issue entirely. By keeping the sample frozen throughout the drying process, it maintains the integrity and biological activity of these delicate structures, which is crucial for reliable experiments and valid research findings.

Extending Shelf Life for Long-Term Stability

Water enables the chemical and biological reactions that cause degradation. By removing up to 99% of the moisture, freeze drying effectively halts these processes.

This results in a highly stable, inert product that can be stored for years at room temperature or with minimal refrigeration, preserving valuable samples for future analysis.

Maintaining the Original Physical Structure

Because the water turns directly from a solid to a gas, it leaves behind a porous, unaltered scaffold of the original material.

This prevents the shrinkage, cracking, and collapse that often occur with traditional heat-drying methods, ensuring the final product maintains its shape, size, and structure.

Superior Rehydration and Usability

The porous structure left behind by sublimation creates a product that can be rehydrated almost instantly and completely. The final dried material is also lightweight and compact, making it easy to store and transport.

Key Considerations and Limitations

While powerful, freeze drying is not a universal solution. It's important to recognize its specific context and limitations to make an informed decision.

It Is a Slow Process

Sublimation is a much slower process than evaporation. A typical freeze-drying cycle can take anywhere from several hours to several days to complete, depending on the sample size and type.

The Equipment is a Significant Investment

Laboratory freeze dryers are complex machines with refrigeration and high-vacuum systems. This makes them significantly more expensive to purchase and maintain than simple ovens or desiccators.

High Energy Consumption

Running both a powerful refrigeration compressor and a vacuum pump for an extended period consumes a considerable amount of energy, contributing to higher operational costs.

Making the Right Choice for Your Goal

Ultimately, the decision to use a freeze dryer depends on the nature of your sample and your preservation goals.

- If your primary focus is preserving biological activity (e.g., proteins, vaccines, microbes): Freeze drying is the industry standard and the most reliable method available.

- If your primary focus is creating stable samples for long-term archival: This is the ideal method for ensuring sample integrity over many years.

- If your primary focus is simply removing water from a robust, non-sensitive material: A more cost-effective method like oven drying may be sufficient.

Choosing the correct preservation technique is fundamental to protecting the value and integrity of your work.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Preservation of Biological Activity | Maintains integrity of proteins, vaccines, and cell cultures by avoiding heat damage. |

| Extended Shelf Life | Removes up to 99% moisture, enabling long-term storage at room temperature. |

| Maintained Physical Structure | Prevents shrinkage and collapse, preserving the sample's original form. |

| Superior Rehydration | Porous structure allows for quick and complete rehydration when needed. |

Protect the integrity of your most sensitive samples with a freeze dryer from KINTEK.

As a leading provider of laboratory equipment and consumables, KINTEK understands that your research depends on reliable sample preservation. Our laboratory freeze dryers (lyophilizers) are engineered to deliver the gentle, precise drying necessary for pharmaceuticals, biotechnology, and life sciences.

We provide solutions that help you:

- Ensure Valid Results: Preserve the biological activity of enzymes, antibodies, and cultures.

- Achieve Long-Term Stability: Archive valuable samples for years without degradation.

- Optimize Your Workflow: With equipment designed for efficiency and ease of use.

Ready to enhance your lab's capabilities? Contact our experts today to find the perfect freeze-drying solution for your specific needs.

Visual Guide

Related Products

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

- Custom PTFE Teflon Parts Manufacturer for PTFE Tweezers

- 30T 40T Split Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Electric Heated Hydraulic Vacuum Heat Press for Lab

People Also Ask

- What is the principle of graphite furnace? Achieve Extreme Temperatures with Direct Resistive Heating

- Why is a high-vacuum graphite heating element furnace used for HAp sintering? Achieve Pure, High-Bond Coatings

- What is the temperature range of a graphite furnace? Unlock up to 3000°C for advanced materials processing.

- What are the steps in the manufacturing of graphite? From Raw Coke to High-Performance Material

- What is the graphite furnace method? Achieve Ultra-High Temperatures with Purity & Speed