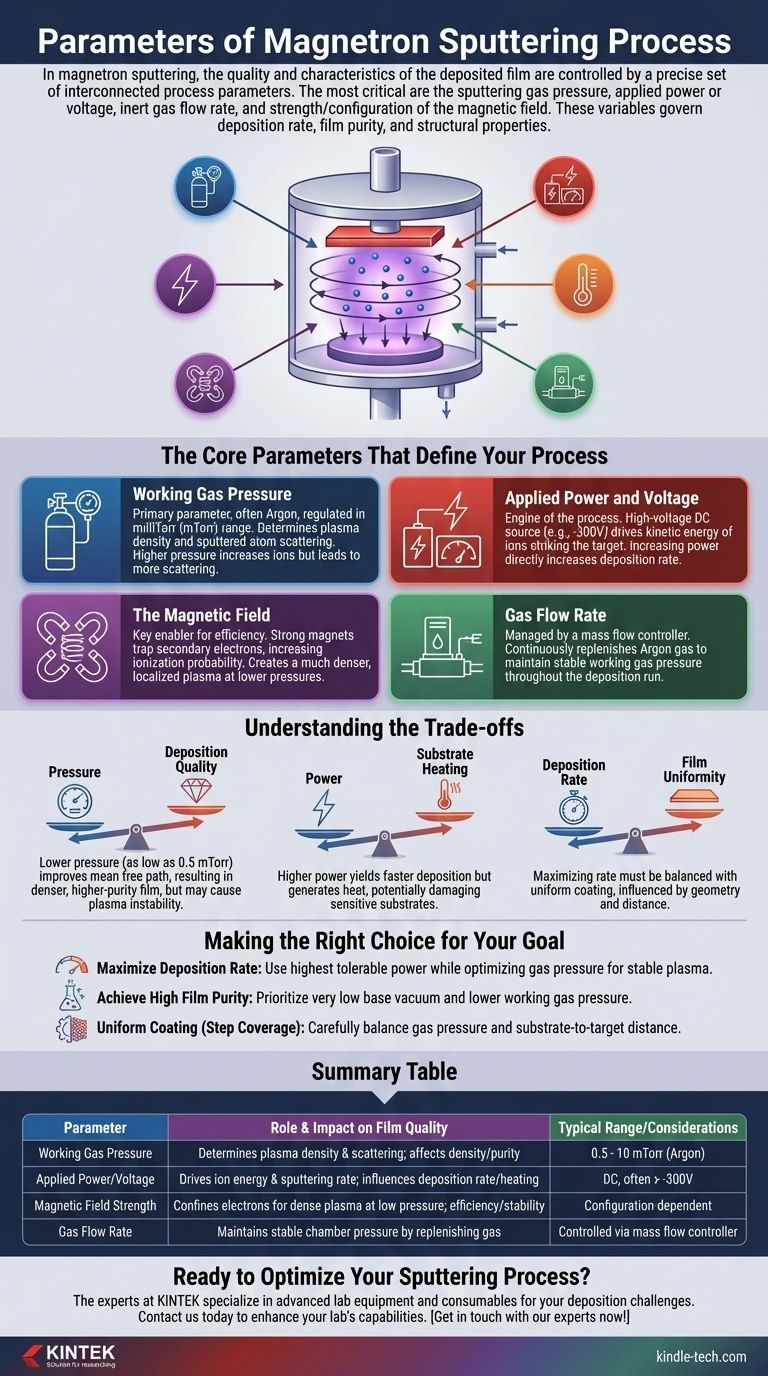

In magnetron sputtering, the quality and characteristics of the deposited film are controlled by a precise set of interconnected process parameters. The most critical of these are the sputtering gas pressure, the applied power or voltage to the target, the inert gas flow rate, and the strength and configuration of the magnetic field. These variables work together to govern the rate of deposition, the film's purity, and its final structural properties.

The core principle is not just controlling individual parameters, but understanding their interplay. The magnetic field is the key enabler—it traps electrons to create a dense plasma at low pressures, which in turn allows high-energy ion bombardment driven by voltage, ultimately determining the deposition rate and film quality.

The Core Parameters That Define Your Process

To achieve a desired outcome, you must understand how each primary parameter influences the sputtering environment inside the deposition chamber.

Working Gas Pressure

The process begins by flowing an inert gas, almost always Argon, into the vacuum chamber. The pressure of this gas is a fundamental parameter.

This pressure, typically regulated in the milliTorr (mTorr) range, determines the density of atoms available to be ionized and used for sputtering.

A higher pressure increases the number of available ions but can also lead to unwanted collisions, scattering sputtered material and reducing the "line of sight" deposition quality.

Applied Power and Voltage

Power, typically from a high-voltage DC source, is the engine of the sputtering process.

A strong negative voltage (often -300V or more) is applied to the target material. This potent negative charge aggressively attracts the positively charged Argon ions from the plasma.

Increasing the power or voltage directly increases the kinetic energy of these ions as they strike the target. This results in more target atoms being ejected per ion, leading to a higher deposition rate.

The Magnetic Field

The magnetic field is what differentiates magnetron sputtering from simpler diode sputtering. It is the key to its efficiency.

Strong magnets placed behind the sputtering target generate a magnetic field parallel to the target's surface. This field traps secondary electrons released during ion bombardment, forcing them into long, spiral paths near the target.

This electron-trapping drastically increases the probability of electrons colliding with and ionizing neutral Argon atoms. The result is a much denser, more localized plasma that can be sustained at significantly lower pressures.

Gas Flow Rate

The gas flow rate, managed by a mass flow controller, works in tandem with the vacuum pumping system.

Its function is to continuously replenish the Argon gas as it is consumed or pumped away, ensuring the working gas pressure remains stable throughout the deposition run.

Understanding the Trade-offs

Optimizing a magnetron sputtering process is an exercise in balancing competing factors. Changing one parameter will invariably affect others.

Pressure vs. Deposition Quality

While a certain gas pressure is necessary to create the plasma, the magnetic field allows this to be very low (as low as 0.5 mTorr).

Operating at lower pressures improves the mean free path of the sputtered atoms. This means they travel from the target to the substrate with fewer collisions, resulting in a denser, higher-purity film.

However, operating at too low a pressure can make the plasma unstable or extinguish it entirely, halting the process.

Power vs. Substrate Heating

A higher power level yields a faster deposition rate, which is often desirable for manufacturing efficiency.

However, the high-energy bombardment of the substrate by sputtered atoms and plasma ions also generates significant heat. Excessive substrate heating can induce stress, cause unwanted phase changes in the film, or damage sensitive substrates.

Deposition Rate vs. Film Uniformity

Achieving a high deposition rate is often a primary goal, but it must be balanced with the need for a uniform coating.

The geometry of the sputter gun, the magnetic field shape, and the distance to the substrate all influence how evenly the material is deposited. Simply maximizing power might create a thick film in the center but a thin film at the edges.

Making the Right Choice for Your Goal

The ideal parameters are dictated entirely by the desired properties of the final thin film.

- If your primary focus is maximizing deposition rate: You will likely operate at the highest power your target and substrate can tolerate while optimizing the gas pressure to maintain a stable, dense plasma without excessive scattering.

- If your primary focus is achieving high film purity and density: You will prioritize starting with a very low base vacuum and using a lower working gas pressure, which is made possible by the magnetron's efficient plasma confinement.

- If your primary focus is uniform coating over a complex surface (step coverage): You may need to carefully balance gas pressure and substrate-to-target distance to control the directionality and scattering of the sputtered atoms.

Mastering these parameters transforms magnetron sputtering from a complex process into a precise and repeatable manufacturing tool.

Summary Table:

| Parameter | Role & Impact on Film Quality | Typical Range/Considerations |

|---|---|---|

| Working Gas Pressure | Determines plasma density & sputtered atom scattering; affects film density and purity. | 0.5 - 10 mTorr (Argon) |

| Applied Power/Voltage | Drives ion energy & sputtering rate; directly influences deposition rate and substrate heating. | DC, often > -300V |

| Magnetic Field Strength | Confines electrons to create dense plasma at low pressure; key for efficiency and stability. | Configuration-dependent |

| Gas Flow Rate | Maintains stable chamber pressure by replenishing sputtered/pumped gas. | Controlled via mass flow controller |

Ready to Optimize Your Sputtering Process?

Achieving the perfect balance of magnetron sputtering parameters is critical for producing high-quality, uniform thin films. The experts at KINTEK specialize in providing advanced lab equipment and consumables tailored to your specific deposition challenges. Whether your goal is maximizing deposition rate, ensuring high film purity, or achieving superior step coverage, we have the solutions and expertise to support your research and production needs.

Contact us today to discuss how our specialized sputtering systems and consumables can enhance your laboratory's capabilities and help you achieve precise, repeatable results.

Get in touch with our experts now!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

People Also Ask

- What is the difference between biomass briquettes and pellets? Choose the Right Fuel for Your Heating System

- What is the process of sputtering in a vacuum? A Guide to High-Purity Thin Film Deposition

- Why graphite has high thermal conductivity? Unlock Superior Heat Management with Its Unique Structure

- What are the different types of XRF samples? A Guide to Solid, Powder, and Liquid Prep

- Why KBr is used to make the pellet? Achieve High-Quality FTIR Analysis of Solid Samples

- How are electron beams made? From Thermionic to Field Emission Explained

- What are the advantages of RF magnetron sputtering? Achieve Superior Thin Film Deposition for Insulating Materials

- What are alternatives to lab-grown diamonds? Compare Natural Diamonds, Moissanite & More