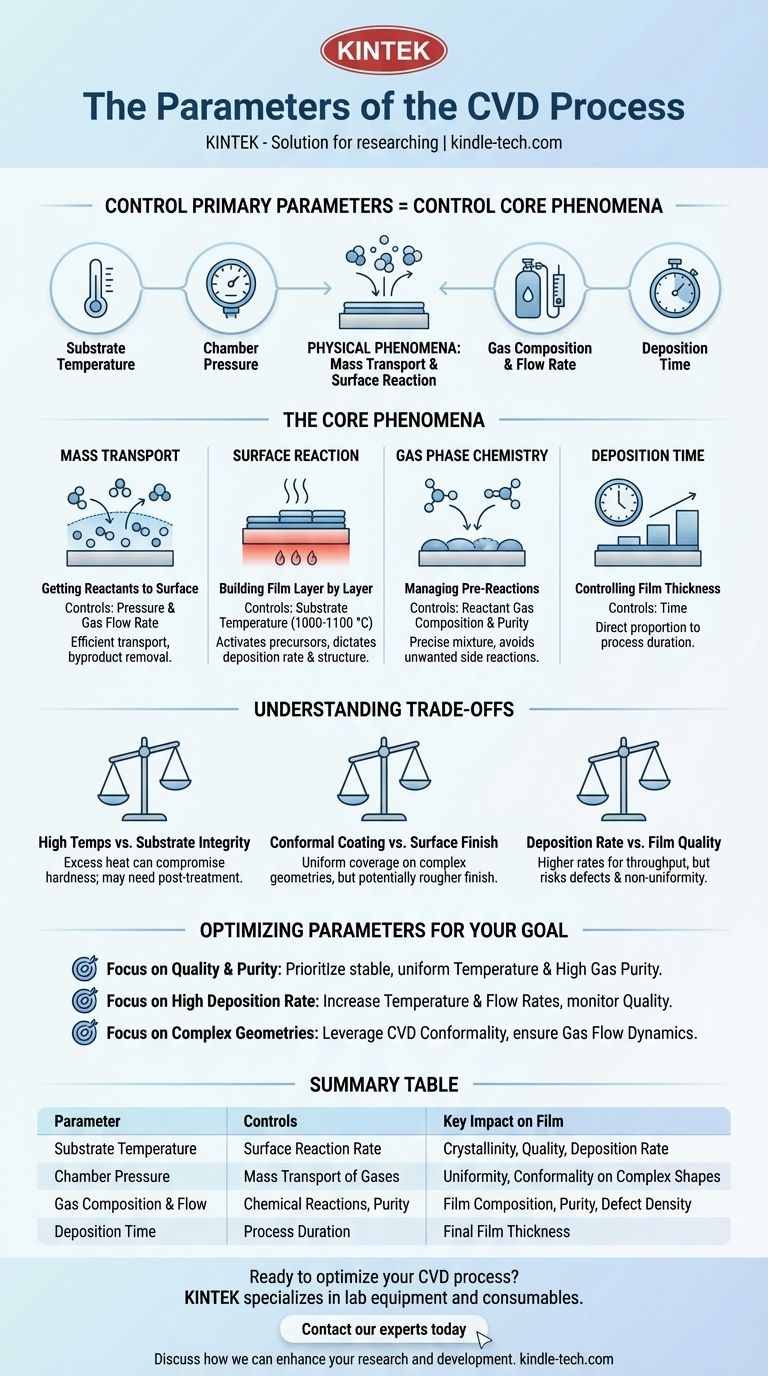

At its core, Chemical Vapor Deposition (CVD) is controlled by four primary parameters. These are the substrate temperature, the chamber pressure, the composition and flow rate of the reactant gases, and the deposition time. By precisely manipulating these variables, you can dictate the characteristics of the resulting thin film, from its thickness and uniformity to its chemical and physical properties.

The key to mastering CVD is understanding that you are not just adjusting isolated parameters. You are using these parameters as levers to control the fundamental physical phenomena of the process: the transport of reactants to the surface and the chemical reactions that form the film.

The Core Phenomena Controlled by CVD Parameters

To effectively control a CVD process, you must think beyond the individual settings and understand the underlying physical and chemical events they influence. The entire process is a delicate balance between getting reactants to the right place and making them react correctly.

Mass Transport: Getting Reactants to the Surface

Before any deposition can occur, the gaseous reactant molecules (precursors) must travel from the main gas flow to the substrate surface. This journey happens through diffusion across a stationary "boundary layer" of gas that exists just above the substrate.

The key parameters controlling this are pressure and gas flow rate. A lower chamber pressure (a low vacuum) and a steady gas flow ensure that reactants can efficiently reach the surface and that byproducts are effectively carried away.

Surface Reaction: Building the Film Layer by Layer

This is the heart of the CVD process. Once reactant molecules adsorb (stick) onto the heated substrate, they undergo chemical reactions that form the solid film and release volatile byproducts.

The single most critical parameter here is substrate temperature. High temperatures, often in the range of 1000-1100 °C, provide the necessary thermal energy to activate the precursors and drive the surface reactions. The specific temperature directly influences the deposition rate and the resulting film's crystalline structure and quality.

Gas Phase Chemistry: Managing Pre-Reactions

Sometimes, chemical reactions begin in the gas phase before the precursors even reach the substrate. This can be beneficial or detrimental depending on the desired outcome.

This is primarily controlled by the reactant gas composition and its purity. Introducing a precise gas mixture is essential. It is also why processes often include steps to purge the chamber of residual air and use dehydration systems to remove moisture, as these impurities can cause unwanted side reactions.

Deposition Time: Controlling Film Thickness

The final, most straightforward parameter is time. Assuming all other parameters are held constant, the thickness of the deposited film is directly proportional to the duration of the process.

A typical deposition and cooling cycle can take 20-30 minutes, but this is highly dependent on the specific material being deposited and the desired thickness.

Understanding the Trade-offs and Practical Realities

Controlling CVD parameters involves navigating a series of critical trade-offs that impact both the process and the final product.

High Temperatures vs. Substrate Integrity

The very high temperatures required for many CVD processes often exceed the tempering temperature of materials like high-speed steel. This means the substrate's hardness can be compromised during coating.

Consequently, tools coated with high-temperature CVD must often undergo a secondary vacuum heat treatment after coating to restore their necessary mechanical properties.

Conformal Coating vs. Surface Finish

A major strength of CVD is its ability to produce highly conformal coatings. Because the process uses a gaseous environment, it can uniformly coat all exposed surfaces, including complex internal geometries and deep, narrow holes.

The trade-off is that CVD coatings often have a slightly rougher surface finish than the original substrate, which may require post-processing for applications demanding extreme smoothness.

Deposition Rate vs. Film Quality

There is a constant tension between the speed of the process and the quality of the film. Increasing temperature and reactant flow rates will generally increase the deposition rate, which is good for throughput.

However, pushing the rate too high can lead to defects, poor crystallinity, or non-uniformity in the film. Process optimization is about finding the sweet spot that delivers acceptable quality at an efficient rate.

Optimizing Parameters for Your Goal

The ideal parameters are entirely dependent on your objective. Use these principles as a starting point for process development.

- If your primary focus is film quality and purity: Prioritize stable and uniform substrate temperature control and ensure high purity of your reactant gases.

- If your primary focus is high deposition rate: Carefully increase substrate temperature and reactant flow rates, while closely monitoring film quality for any degradation.

- If your primary focus is coating complex geometries: Leverage CVD's natural advantage, but ensure your gas flow dynamics are sufficient to replenish reactants and remove byproducts from deep features.

Ultimately, mastering CVD is about methodically balancing these interconnected parameters to achieve a specific outcome on the substrate.

Summary Table:

| Parameter | Controls | Key Impact on Film |

|---|---|---|

| Substrate Temperature | Surface Reaction Rate | Crystallinity, Quality, Deposition Rate |

| Chamber Pressure | Mass Transport of Gases | Uniformity, Conformality on Complex Shapes |

| Gas Composition & Flow | Chemical Reactions, Purity | Film Composition, Purity, Defect Density |

| Deposition Time | Process Duration | Final Film Thickness |

Ready to optimize your Chemical Vapor Deposition process?

KINTEK specializes in lab equipment and consumables, providing the precise tools and expert support you need to master CVD parameters and achieve superior thin films. Whether your goal is high-purity coatings, high deposition rates, or uniform coverage on complex geometries, we have the solutions for your laboratory.

Contact our experts today to discuss how we can help you enhance your research and development.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What is the precursor gas in PECVD? The Key to Low-Temperature Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- How plasma is generated in PECVD? A Step-by-Step Breakdown of the Process

- How is PECVD different from CVD? Unlock Low-Temperature Thin Film Deposition

- What is the difference between CVD and PVD process? A Guide to Choosing the Right Coating Method