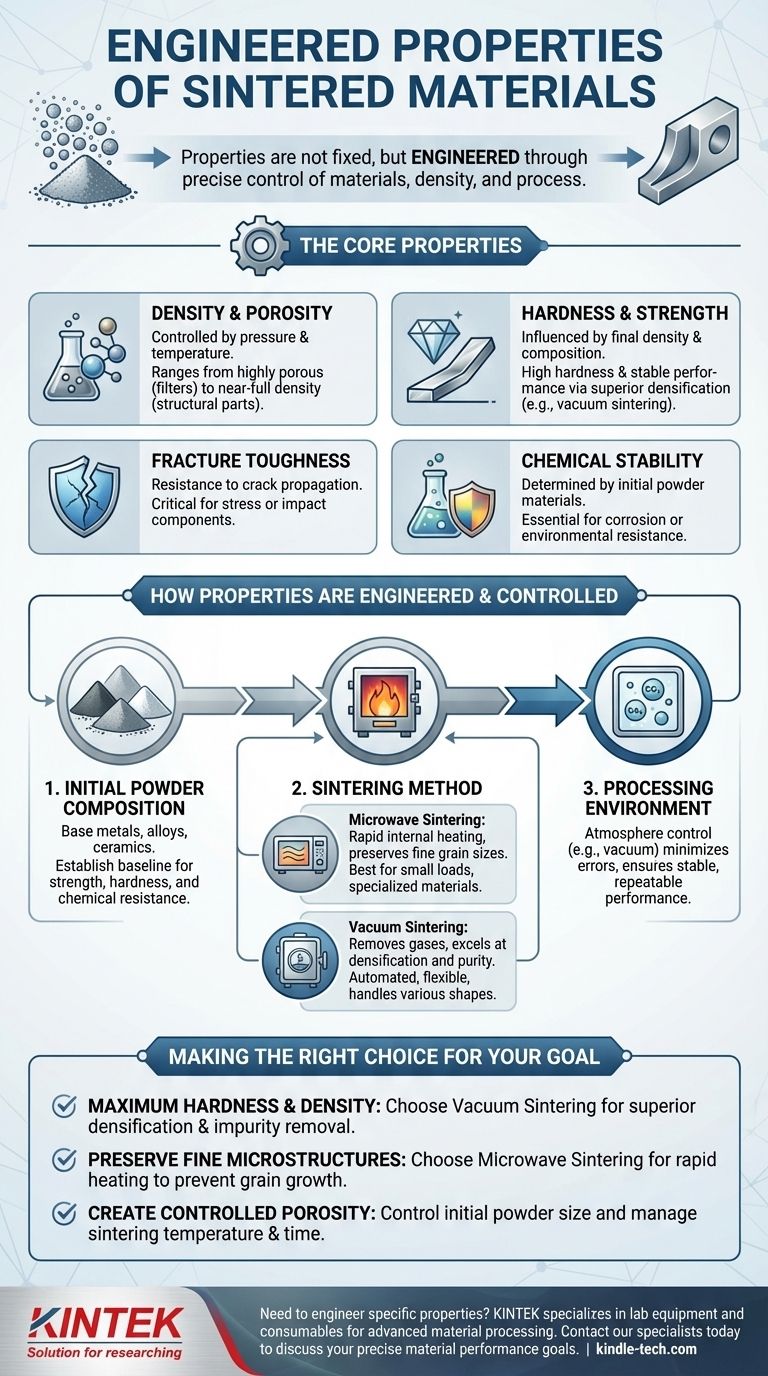

The single most important characteristic of sintered materials is that their properties are not fixed, but engineered. By precisely controlling the base materials, density, and manufacturing process, it's possible to create components with a wide range of specific physical and mechanical properties, including high hardness, controlled porosity, excellent strength, and chemical stability.

Sintering is fundamentally a process of control. The final properties of a component are a direct result of deliberate choices made about the initial powder composition and the specific sintering technique used, allowing for performance characteristics that are tailored to the application.

The Core Properties of Sintered Components

Sintering allows for the deliberate engineering of several key material properties. These are not independent variables; a change in one, such as density, will directly impact others, like strength and hardness.

Density and Porosity

The most fundamental property controlled through sintering is density. By adjusting process parameters like pressure and temperature, manufacturers can create parts ranging from highly porous (for filters) to nearly fully dense (for structural components). This is often measured using the Archimedes method.

Hardness and Strength

Hardness (resistance to surface indentation) and bending strength (resistance to breaking under a load) are directly influenced by the material's final density and composition. Processes like vacuum sintering are known for producing parts with high hardness and stable performance due to superior densification.

Fracture Toughness

Fracture toughness measures a material's ability to resist the propagation of cracks. This is a critical property for components subjected to stress or impact. The indentation method is a common way to measure this characteristic in sintered parts.

Chemical Stability

The chemical stability of a sintered part is largely determined by the initial powder materials used in the mix. This is especially critical in sintered ceramics, where resistance to corrosion or reaction with the environment is a primary design requirement.

How Properties are Engineered and Controlled

The final properties of a sintered component are not accidental. They are the outcome of a series of deliberate engineering decisions that begin with the raw materials and extend through the entire manufacturing cycle.

The Initial Powder Composition

Everything starts with the powder. The choice of base metals, alloys, or ceramic compounds establishes the potential range of final properties. The blend of these powders determines the baseline for strength, hardness, and chemical resistance before the sintering process even begins.

The Sintering Method

The technique used to apply heat and pressure has a profound impact. Different methods generate heat in different ways, which affects the final microstructure of the material.

For example, microwave sintering generates heat internally, which can be faster and more energy-efficient while preserving very fine grain sizes. In contrast, conventional methods heat the material from the outside in.

The Processing Environment

The atmosphere in which sintering occurs is critical. Vacuum sintering, for instance, removes gases from the raw materials, leading to products with better densification and purity. This controlled environment minimizes human error and ensures stable, repeatable performance.

Understanding the Trade-offs: Process vs. Outcome

Choosing a sintering process involves balancing speed, cost, scale, and the desired final properties. No single method is universally superior; each comes with a distinct set of advantages and limitations.

Microwave Sintering

This advanced method is excellent for processing small loads quickly and efficiently. Its ability to maintain fine microstructures makes it highly effective for specialized applications like bioceramics.

However, its productivity is limited as it often sinters one part at a time. Furthermore, microwaves only penetrate a short distance in conductive materials, and some powders may not heat effectively at all.

Vacuum Sintering

This process excels at producing highly dense, hard, and pure components with stable, repeatable performance. Its high level of automation and flexibility allows it to handle various product shapes and sizes effectively.

The primary considerations for vacuum sintering revolve around the equipment's complexity and the batch nature of the process, which can influence cycle times and overall throughput compared to continuous sintering methods.

Making the Right Choice for Your Goal

The optimal approach to sintering depends entirely on the intended application and the most critical performance characteristic.

- If your primary focus is maximum hardness and density: A process like vacuum sintering is often the ideal choice, as it excels at removing impurities and achieving superior densification.

- If your primary focus is preserving fine microstructures in advanced materials: Consider microwave sintering, which offers rapid heating that can prevent grain growth.

- If your primary focus is creating a porous material for filtration: The key is to control the initial powder size and limit the final density through careful management of sintering temperature and time.

Ultimately, the power of sintering lies in its ability to transform simple powders into complex, high-performance components with precisely engineered properties.

Summary Table:

| Key Property | Description & Control | Common Application |

|---|---|---|

| Density & Porosity | Controlled by pressure & temperature. Ranges from highly porous to near-full density. | Filters, Structural Parts |

| Hardness & Strength | Directly influenced by final density and composition. Enhanced by processes like vacuum sintering. | Cutting Tools, Wear Parts |

| Fracture Toughness | Resistance to crack propagation. Critical for impact or stress-bearing components. | Engine Parts, Industrial Tools |

| Chemical Stability | Determined by the initial powder materials, especially in ceramics. | Corrosion-Resistant Components, Bioceramics |

Need to engineer a component with specific properties? The experts at KINTEK are here to help. We specialize in lab equipment and consumables for advanced material processing, including sintering technologies. Whether your goal is maximum hardness, controlled porosity, or superior chemical stability, we can provide the right solutions for your laboratory's needs.

Contact our specialists today to discuss how we can help you achieve precise material performance.

Visual Guide

Related Products

- Electric Split Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

People Also Ask

- What are the considerations of powder metallurgy? Key Factors for Manufacturing Success

- Why is cold working better than hot working? A Guide to Choosing the Right Metal Forming Process

- Purpose of CIP in c-LLZO ceramic pellets? Achieve >90% Density & Superior Uniformity with Cold Isostatic Pressing

- What is the process of CIP and HIP? Forming vs. Densifying for Superior Materials

- What are the applications of cold isostatic pressing? Achieve Uniform Density for Complex Parts