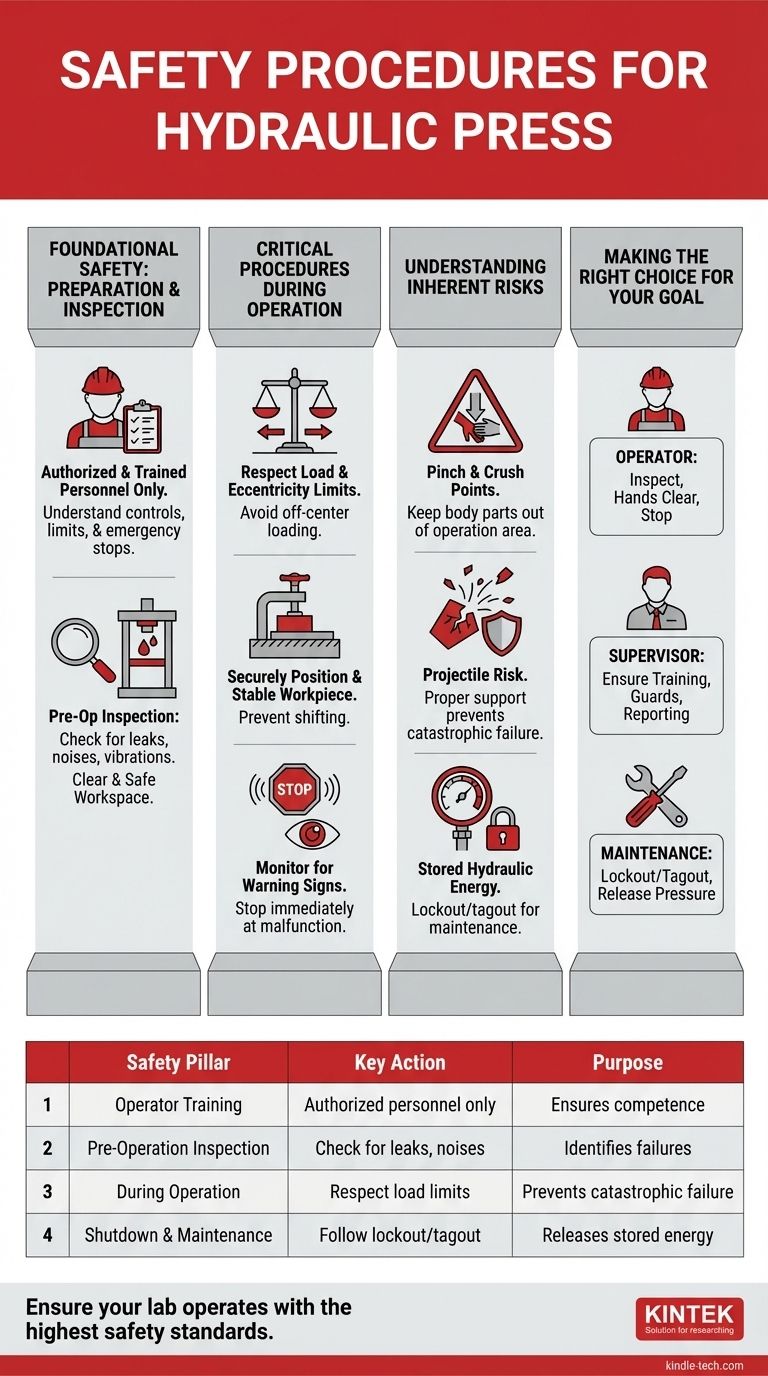

At its core, hydraulic press safety is a disciplined process built on four pillars: proper training, pre-operation inspection, adherence to load limits, and a standardized shutdown procedure. Only authorized personnel may operate the machine, and it must be stopped immediately if any signs of malfunction—such as oil leaks, unusual noises, or excessive vibration—are detected.

A hydraulic press multiplies force to an unforgiving degree. Therefore, safety is not merely a checklist but a constant state of awareness. The goal is to manage this immense energy and prevent catastrophic failure by understanding and respecting the machine's operational limits at all times.

Foundational Safety: Preparation and Inspection

Before any work begins, the operator and the machine must be properly prepared. This foundational stage is the most critical for preventing incidents.

The Operator is the First Line of Defense

Only personnel who have received specific, documented training on the press they are using should be authorized to operate it. This training ensures they understand the machine's unique controls, limits, and emergency stop procedures.

Inspecting the Machine's Health

Before every use, conduct a visual inspection. Look for hydraulic oil leaks on the floor or around fittings, as this can indicate a loss of pressure or a pending hose failure. Listen for any loud or unusual noises and feel for abnormal vibrations during startup, as these are often the first signs of internal mechanical problems.

Maintaining a Clear and Safe Workspace

The area around the hydraulic press must be kept completely clear of tools, materials, and other obstructions. A clean workspace prevents trip hazards and ensures you have a clear path to move away from the press in an emergency.

Critical Procedures During Operation

While the press is active, your focus must be on the workpiece and the machine's feedback.

Respecting Load and Eccentricity Limits

Never exceed the press's maximum tonnage rating. Equally important is to avoid eccentricity, which is off-center loading. Placing a workpiece off-center concentrates the machine's entire force on one side, creating dangerous stress on the frame and ram that can lead to component failure.

Securing the Workpiece

Ensure the workpiece is positioned securely and is stable on the press bed. An improperly placed part can shift or tilt under pressure, potentially causing it to be ejected from the press at high velocity or creating a sudden, dangerous eccentric load.

Monitoring for Warning Signs

Constant vigilance is key. If you see, hear, or feel anything abnormal during the pressing cycle—new noises, increased vibration, or leaks—stop the machine immediately. Do not attempt to "push through" a problem.

Understanding the Inherent Risks

Trusting the machine requires understanding its potential for failure. A hydraulic press is simple in principle but harbors immense stored energy.

The Danger of Pinch and Crush Points

The most obvious risk is the crush hazard between the ram and the press bed. Always keep your hands and all body parts out of the point of operation. Use appropriate tools to load and unload workpieces.

The Projectile Risk

A failing component or a shattered workpiece can become a projectile with lethal force. This is why respecting load limits and ensuring the workpiece is properly supported is not optional—it is essential for preventing catastrophic failure.

The Hazard of Stored Hydraulic Energy

Even when a press is turned off, the hydraulic system can retain high-pressure fluid. This stored energy can cause injury if a line is disconnected or a component is removed improperly. Maintenance and repair require specific lockout/tagout and pressure-release procedures.

Making the Right Choice for Your Goal

Adherence to safety protocols must be adapted to your specific role and responsibilities.

- If your primary focus is operating the press: Always perform a pre-use inspection, never place your hands in the die area, and stop immediately if you suspect a problem.

- If your primary focus is supervising the work area: Ensure that only trained and authorized personnel use the press, that safety guards are in place, and that there is a clear and enforced procedure for reporting malfunctions.

- If your primary focus is maintenance and repair: Always follow full lockout/tagout procedures and safely release all stored hydraulic pressure before beginning any work on the machine.

Ultimately, safety is a proactive discipline, not a reactive measure.

Summary Table:

| Safety Pillar | Key Action | Purpose |

|---|---|---|

| Operator Training | Authorized personnel only | Ensures competence with controls and emergency stops |

| Pre-Operation Inspection | Check for leaks, noises, vibrations | Identifies potential failures before use |

| During Operation | Respect load limits, avoid eccentric loading | Prevents catastrophic machine failure |

| Shutdown & Maintenance | Follow lockout/tagout procedures | Safely releases stored hydraulic energy |

Ensure your lab operates with the highest safety standards. Proper equipment is the foundation of a safe workflow. KINTEK specializes in reliable lab equipment and consumables, serving laboratory needs with precision-engineered hydraulic presses and safety accessories.

Contact us today to discuss your specific requirements and let our experts help you build a safer, more efficient lab environment.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Manual Lab Heat Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation