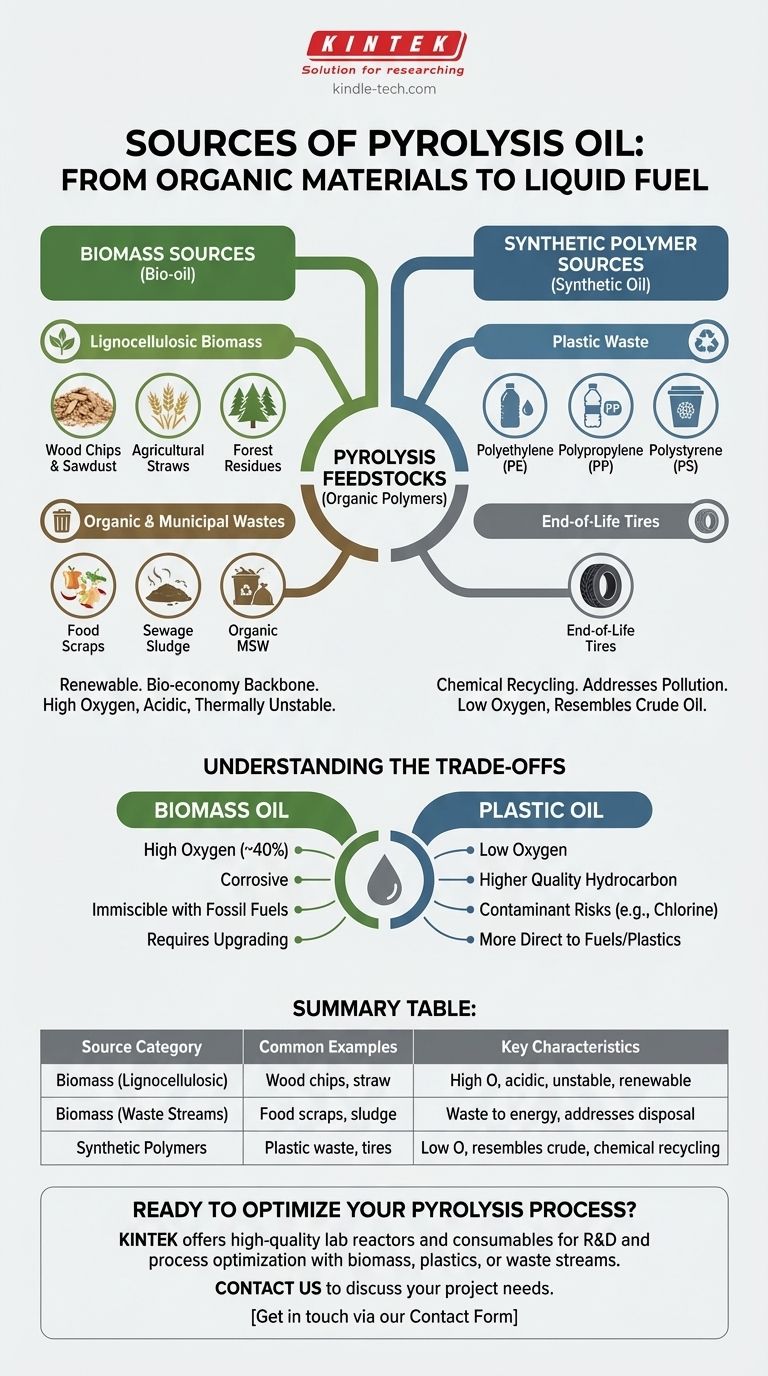

In short, the primary sources for pyrolysis oil are organic materials, most notably biomass (like wood and agricultural waste) and plastic waste. The process converts these solid feedstocks into a liquid fuel or chemical precursor, often referred to as bio-oil or pyrolysis oil.

Pyrolysis is fundamentally a conversion technology. The choice of source material is the single most important factor, as it dictates not only the chemical properties and quality of the final oil but also the economic and environmental viability of the entire process.

What Defines a Pyrolysis Source?

Pyrolysis is the thermal decomposition of materials in an oxygen-starved environment. Any material rich in organic polymers, whether natural or synthetic, can theoretically be used as a feedstock.

The Core Requirement: Organic Polymers

For a material to be a viable source, it must be composed of long-chain organic molecules. Heat breaks these large molecules down into smaller, volatile compounds that can be condensed into a liquid oil.

The Ideal Feedstock Characteristics

The best feedstocks generally have low moisture content, as water consumes significant energy to evaporate, reducing the process's efficiency. They should also have low ash (inorganic) content, as this material does not convert to oil and can complicate operations.

Primary Sources: Biomass Feedstocks

When pyrolysis oil is derived from biomass, it is often called bio-oil. These sources are renewable and form the backbone of the bio-economy.

Lignocellulosic Biomass

This is the most common category and includes plant matter composed of cellulose, hemicellulose, and lignin.

Examples include wood chips, sawdust, forest residues, agricultural straws (like wheat or corn stover), and dedicated energy crops like switchgrass. Oil from these sources is high in oxygen, making it acidic and thermally unstable.

Organic and Municipal Wastes

This category focuses on turning waste streams into valuable products.

Sources include food scraps, sewage sludge, and the organic fraction of municipal solid waste (MSW). This approach simultaneously addresses waste management challenges and energy production.

Emerging Sources: Synthetic Polymers

Using synthetic polymers is a powerful tool for chemical recycling and addressing pollution from materials that do not easily biodegrade.

Plastic Waste

Pyrolysis can effectively break down common plastics like polyethylene (PE), polypropylene (PP), and polystyrene (PS) into a synthetic oil.

This oil has a much lower oxygen content than biomass-derived oil and more closely resembles a conventional crude oil, making it a promising feedstock for producing new plastics or fuels.

End-of-Life Tires

Scrap tires are a significant global waste problem. Pyrolysis breaks them down into a hydrocarbon-rich oil, a solid carbon char (carbon black), and steel, recovering value from all components.

Understanding the Trade-offs

The source material is not just an input; it defines the output. Choosing a feedstock involves critical trade-offs between oil quality, process complexity, and environmental goals.

The Biomass vs. Plastic Dilemma

Oil from biomass is renewable but has challenging properties. Its high oxygen content (up to 40%) makes it corrosive, immiscible with fossil fuels, and prone to aging and polymerization, requiring significant upgrading to be used as a transport fuel.

Oil from plastics, on the other hand, is a higher-quality hydrocarbon fuel. However, the feedstock can be contaminated with substances like chlorine (from PVC) that can produce highly corrosive acids and toxic byproducts if not managed properly.

The Problem of Contamination and Pre-treatment

Real-world feedstocks are rarely pure. Agricultural residues contain ash and soil. Municipal waste contains a complex mixture of materials.

This "dirty" nature of many feedstocks requires extensive pre-treatment steps like drying, shredding, and sorting. These steps add cost and complexity to the overall process, directly impacting its economic feasibility.

Making the Right Choice for Your Goal

Selecting a pyrolysis feedstock depends entirely on your primary objective.

- If your primary focus is renewable energy and carbon neutrality: Lignocellulosic biomass like wood or agricultural residues is the ideal starting point.

- If your primary focus is waste management and the circular economy: Mixed plastic waste, end-of-life tires, and municipal solid waste are your key targets.

- If your primary focus is producing high-grade fuels or new plastics: Plastic-derived pyrolysis oil offers a more direct pathway with less need for intensive chemical upgrading.

Ultimately, understanding the origin of pyrolysis oil is the first step toward harnessing its potential to solve critical energy and environmental challenges.

Summary Table:

| Source Category | Common Examples | Key Characteristics of Oil Produced |

|---|---|---|

| Biomass (Lignocellulosic) | Wood chips, sawdust, agricultural straw | High oxygen content, acidic, thermally unstable, renewable |

| Biomass (Waste Streams) | Food scraps, sewage sludge, organic MSW | Turns waste into energy, addresses disposal challenges |

| Synthetic Polymers | Plastic waste (PE, PP, PS), end-of-life tires | Low oxygen content, resembles crude oil, enables chemical recycling |

Ready to turn your feedstock into valuable pyrolysis oil? The right lab equipment is critical for R&D and process optimization. KINTEK specializes in high-quality pyrolysis lab reactors and consumables, helping you accurately test and scale your process—whether you're working with biomass, plastics, or waste streams. Contact us today to discuss your project needs and let our experts help you achieve your energy recovery or recycling goals. Get in touch via our Contact Form

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Test Sieves and Sieving Machines

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products