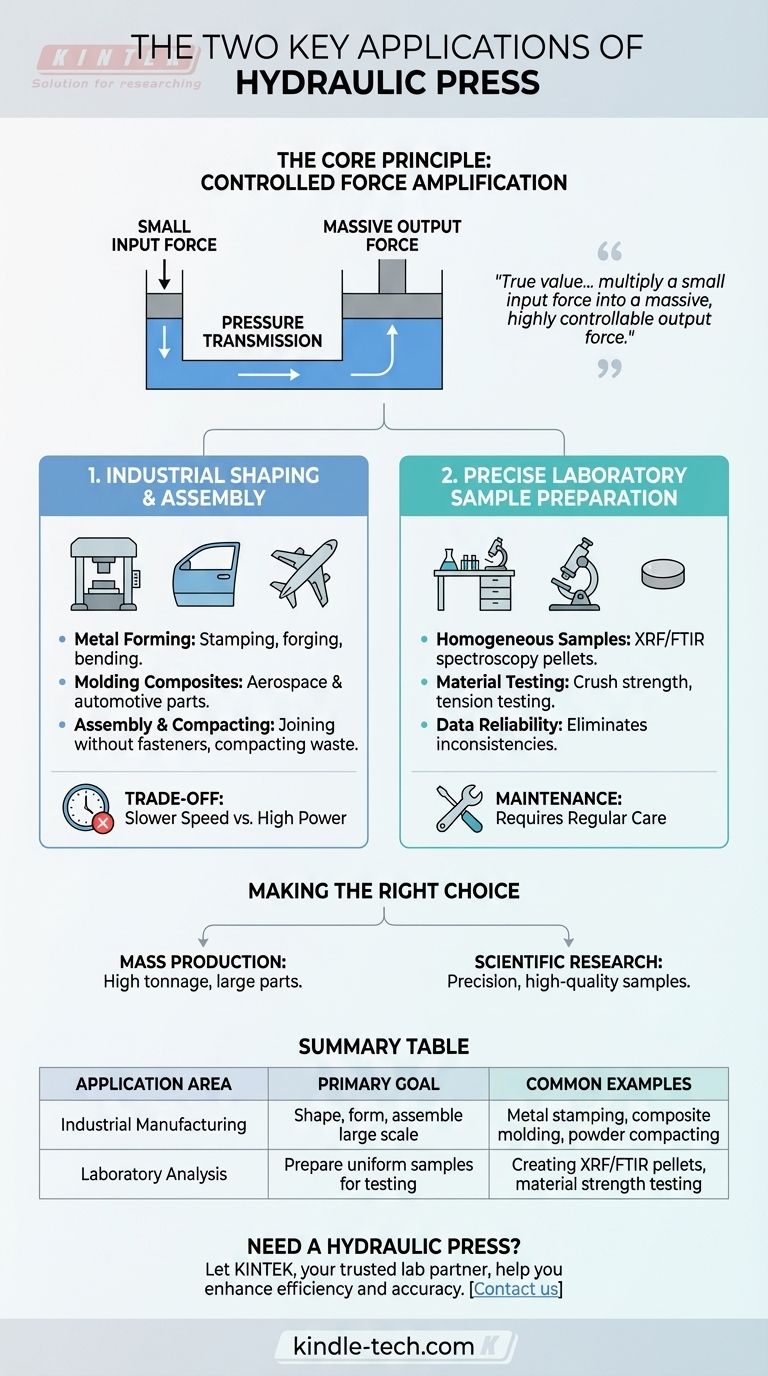

At its core, a hydraulic press is used for two fundamentally different but related purposes: large-scale industrial manufacturing and precise laboratory analysis. In manufacturing, it uses immense force to shape, stamp, or assemble materials like metal. In the lab, it applies controlled pressure to prepare small, uniform samples for scientific testing.

The true value of a hydraulic press isn't in any single application, but in its unique ability to multiply a small input force into a massive, highly controllable output force. This single principle is what makes it indispensable for both shaping car doors and preparing delicate samples for spectroscopic analysis.

The Core Principle: Controlled Force Amplification

A hydraulic press operates on a simple concept known as Pascal's Principle. This principle states that pressure applied to an enclosed fluid is transmitted equally throughout the fluid.

How It Works

A small amount of force is applied to a small piston, which pressurizes hydraulic fluid. This pressure then acts on a much larger piston, generating a proportionally larger output force.

This mechanism allows the press to generate exceptionally high tonnage (force) with a relatively simple and compact design.

The Key Advantage: Controllable Power

Unlike purely mechanical presses that deliver force in a rapid, fixed stroke, a hydraulic press allows for precise control over the pressure. The force can be applied gradually, held constant, and released slowly.

This control is critical for tasks like deep drawing metal or molding complex composite materials without fracturing them.

Application 1: Industrial Shaping and Assembly

In an industrial context, the primary goal is to use immense force to form, cut, or join materials on a large scale.

Metal Forming and Forging

This is the most common application. Hydraulic presses are used to stamp sheet metal into car body panels, forge raw metal billets into engine components, and bend heavy steel plates for construction.

The high tonnage and controlled pressure ensure that the metal deforms into the desired shape without cracking.

Molding Composites and Plastics

Modern manufacturing relies heavily on composites like carbon fiber and advanced plastics. A hydraulic hot press combines heat and pressure to mold these materials.

This is essential in the aerospace and automotive industries for creating strong, lightweight parts, such as body panels and structural components.

Assembling and Compacting

The power of a hydraulic press is also used for assembly operations like clinching, which joins sheets of metal without fasteners. It is also used to compact powders or waste materials into dense blocks.

Application 2: Precise Laboratory Sample Preparation

In a laboratory, the scale is much smaller, but the need for control is even greater. The goal is to prepare perfect samples for accurate analysis.

Creating Homogeneous Samples for Analysis

For techniques like X-ray Fluorescence (XRF) or FTIR Spectroscopy, the sample must be perfectly uniform. A laboratory hydraulic press is used to compress powders into a solid, smooth pellet or thin film.

This process eliminates inconsistencies in the material, ensuring that the analytical instrument reads a representative sample and produces reliable data.

Material Strength and Durability Testing

Engineers and material scientists use hydraulic presses to test the limits of their materials. A sample can be compressed to find its crush strength or placed in a fixture to perform tension testing, where it is pulled apart.

This allows researchers to verify material quality and understand how substances behave under extreme pressure.

Understanding the Trade-offs

While incredibly versatile, hydraulic presses are not the solution for every problem. Understanding their limitations is key to using them effectively.

Speed vs. Power

The primary trade-off for a hydraulic press is speed. They are typically slower than their mechanical counterparts. For high-speed, repetitive tasks like stamping simple metal washers, a mechanical press is often a better choice.

Maintenance and Complexity

While the design concept is simple, a hydraulic system involves fluid, pumps, hoses, and seals. These components require regular maintenance to prevent leaks and ensure the press delivers consistent, reliable pressure over its lifespan.

Making the Right Choice for Your Goal

The application of a hydraulic press is determined entirely by the scale and precision required for the task.

- If your primary focus is mass production and shaping large parts: You need an industrial press for its high tonnage, used in tasks like vehicle part stamping, forging, or molding composite panels.

- If your primary focus is scientific research and quality control: A laboratory press is essential for creating the consistent, high-quality pellets and films required for accurate spectroscopic analysis or material strength testing.

Ultimately, the hydraulic press is a masterclass in versatility, demonstrating how one fundamental principle of physics can be scaled to build everything from an airplane wing to the perfect sample for a scientific breakthrough.

Summary Table:

| Application Area | Primary Goal | Common Examples |

|---|---|---|

| Industrial Manufacturing | Shape, form, or assemble materials on a large scale | Metal stamping, forging, composite molding, powder compacting |

| Laboratory Analysis | Prepare uniform samples for accurate scientific testing | Creating pellets for XRF/FTIR spectroscopy, material strength testing |

Need a Hydraulic Press for Your Specific Application?

Whether you are in industrial manufacturing and require high-tonnage force for shaping materials, or in a laboratory setting needing precise pressure for sample preparation, KINTEK has the right solution for you. Our hydraulic presses are engineered for reliability, control, and performance, ensuring you achieve consistent results every time.

Let KINTEK, your trusted lab equipment partner, help you enhance your efficiency and accuracy.

Contact us today to discuss your requirements and discover how our hydraulic presses can meet your unique needs!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy