Oxidation in heat treatment is a chemical reaction between the hot surface of a metal component and an oxidizing agent, most commonly oxygen. As the metal's temperature increases, its atoms become more reactive, dramatically accelerating the rate at which they combine with oxygen from the surrounding atmosphere to form a layer of metal oxide, also known as scale.

The presence of oxygen, amplified by high temperatures, is the direct cause of oxidation. Therefore, successful heat treatment is not just about managing temperature; it is fundamentally about controlling the furnace atmosphere to eliminate or displace the oxygen that damages your parts.

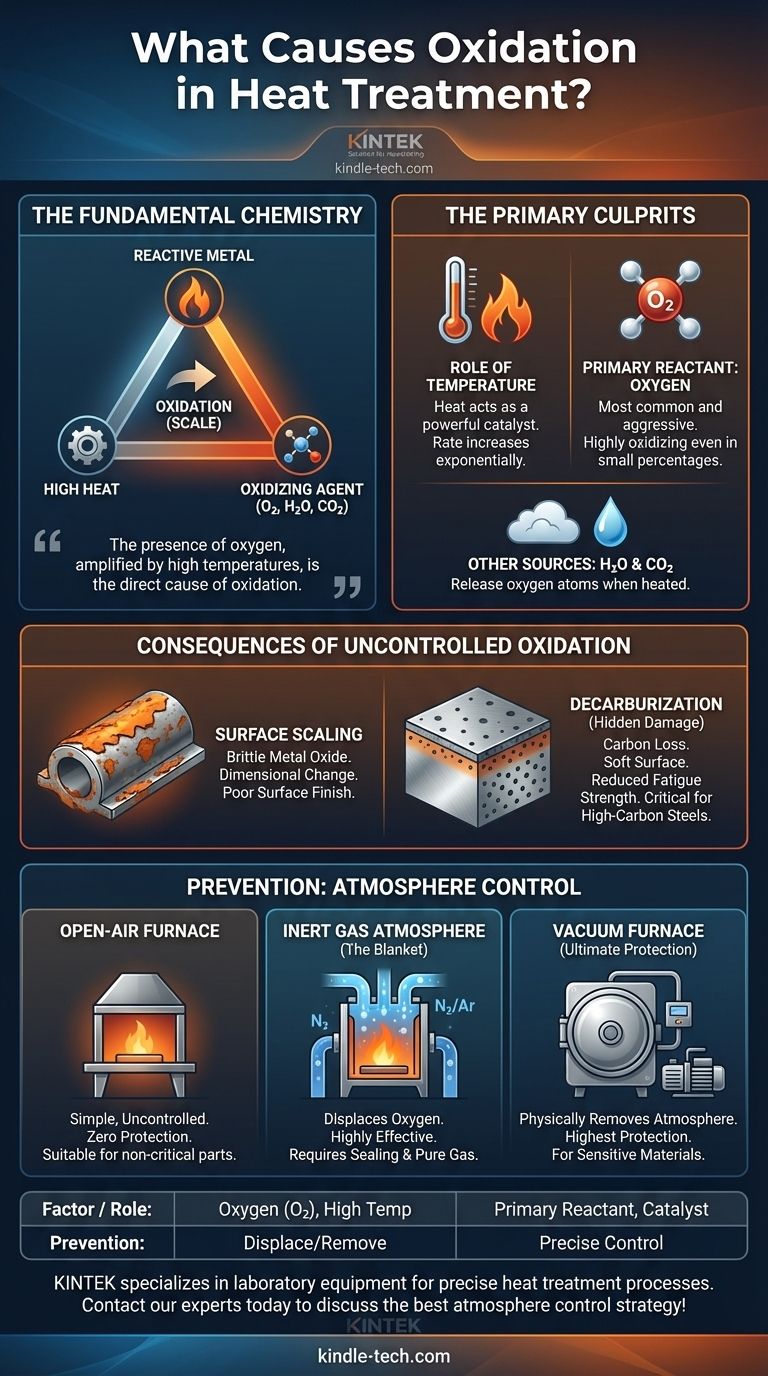

The Fundamental Chemistry of Oxidation

To prevent oxidation, you must first understand the elements that cause it. The process is a simple but destructive triangle: a reactive metal, sufficient heat, and an oxidizing agent.

The Role of Temperature

Heat acts as a powerful catalyst for oxidation. At room temperature, most engineering metals like steel are relatively stable. However, as you apply heat, you are supplying the energy needed to break chemical bonds and initiate the reaction with oxygen.

The rate of oxidation does not increase linearly with temperature; it increases exponentially. This is why a part can emerge from a low-temperature tempering process with minimal discoloration, while the same part can be covered in thick, flaky scale after a high-temperature hardening or annealing cycle.

The Primary Reactant: Oxygen

Oxygen is the most common and aggressive oxidizing agent in heat treatment. It readily combines with the iron in steel (forming iron oxides, or rust and scale) and with other metals like aluminum, titanium, and copper.

Even a small percentage of oxygen in a furnace atmosphere can cause significant surface damage. The air we breathe, which is approximately 21% oxygen, is highly oxidizing at typical heat treatment temperatures.

Other Oxidizing Sources in the Furnace

While atmospheric oxygen is the main culprit, it is not the alone. Water vapor (H₂O) and carbon dioxide (CO₂) are also potent oxidizing agents at high temperatures.

When heated, H₂O and CO₂ can break down and release their oxygen atoms, which then react with the metal surface. This is why using a seemingly "inert" gas that has high moisture content can still lead to unexpected oxidation.

The Consequences of Uncontrolled Oxidation

Oxidation is not merely a cosmetic issue. It can fundamentally compromise the mechanical integrity and dimensional accuracy of a component.

Surface Scaling and Dimensional Change

The most visible result of oxidation is scale, a brittle layer of metal oxide that forms on the component's surface. This scale is often flaky and poorly adhered.

When the scale is removed through cleaning processes like sandblasting or acid pickling, a small amount of the base metal is lost. This results in a loss of dimensional accuracy, which can be critical for high-precision parts. The surface finish is also degraded, becoming rough and pitted.

Decarburization: The Hidden Damage

For carbon steels, a more insidious problem occurs alongside oxidation: decarburization. At high temperatures, oxygen atoms can react not just with the iron, but also with the carbon atoms within the steel's surface layer.

This reaction pulls carbon out of the steel, leaving behind a soft, low-carbon iron layer. A decarburized surface has significantly lower hardness and wear resistance, and dramatically reduced fatigue strength, potentially leading to premature component failure in the field.

Understanding the Trade-offs: Atmosphere vs. Cost

Preventing oxidation involves creating a furnace atmosphere that is free of oxygen and other oxidizing agents. The method you choose involves a direct trade-off between the level of protection and the cost and complexity of the process.

Open-Air Furnaces: Simple but Uncontrolled

Heating a part in an open-air furnace is the simplest and cheapest method. However, it offers zero protection from oxidation. This approach is only suitable for non-critical components or parts that will have their entire surface layer machined away after treatment.

Inert Gas Atmospheres: The Protective Blanket

A common solution is to flood the furnace with an inert gas, such as nitrogen or argon. These gases displace the oxygen, creating a protective "blanket" around the part.

This method is highly effective for preventing general oxidation and scaling. However, it requires a well-sealed furnace to prevent air leaks and a continuous supply of gas, which adds operational cost. Gas purity is also critical, as moisture or oxygen contaminants in the supply can still cause issues.

Vacuum Furnaces: The Ultimate Protection

A vacuum furnace provides the highest level of protection by physically removing the atmosphere—and therefore the oxygen—from the heating chamber. By operating in a near-perfect vacuum, there are virtually no molecules left to react with the hot metal surface.

This is the preferred method for highly sensitive materials (like titanium or refractory metals), high-carbon steels prone to decarburization, and any application requiring a perfectly bright, clean surface finish. The trade-off is significantly higher equipment cost and longer cycle times.

Choosing the Right Approach for Your Application

Selecting the correct atmospheric control strategy is a critical decision based on your material, your budget, and the final requirements for the part.

- If your primary focus is cost-effectiveness for non-critical parts: An open-air furnace may be sufficient, but you must account for post-treatment cleaning and dimensional loss.

- If your primary focus is preventing scaling on standard steels: An inert atmosphere of nitrogen or argon provides a reliable balance of protection and operational cost.

- If your primary focus is a pristine surface finish or protecting sensitive alloys: A vacuum furnace is the most effective and reliable method, ensuring parts emerge clean and dimensionally accurate.

- If your primary focus is preventing surface decarburization in high-carbon tool steels: A high-purity vacuum or a precisely controlled active atmosphere is essential to preserve surface hardness and fatigue life.

Ultimately, mastering heat treatment requires treating the furnace atmosphere with the same precision you apply to temperature and time.

Summary Table:

| Factor | Role in Oxidation | Prevention Method |

|---|---|---|

| Oxygen (O₂) | Primary reactant, forms metal oxide (scale) | Displace with inert gas or use vacuum |

| High Temperature | Catalyst, exponentially increases reaction rate | Precise temperature control is essential |

| Water Vapor (H₂O) & CO₂ | Secondary oxidizing agents | Use dry, high-purity gas supplies |

| Consequence | Impact on Part | Solution Goal |

| Scaling | Dimensional loss, poor surface finish | Eliminate oxygen contact |

| Decarburization | Soft surface, reduced fatigue strength | Protect carbon content in steel |

Protect your critical components from costly oxidation damage. KINTEK specializes in providing laboratory equipment and consumables for precise heat treatment processes. Whether you need an inert gas atmosphere system or a high-performance vacuum furnace, our solutions are designed to deliver clean, dimensionally accurate parts with preserved mechanical properties. Contact our experts today to discuss the best atmosphere control strategy for your application!

Visual Guide

Related Products

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

People Also Ask

- Why nitrogen is used in furnace? A Cost-Effective Shield for High-Temperature Processes

- How we can develop inert atmosphere for a chemical reaction? Master Precise Atmospheric Control for Your Lab

- What is meant by inert atmosphere? A Guide to Preventing Oxidation & Ensuring Safety

- What is the purpose of inert atmosphere? A Guide to Protecting Your Materials and Processes

- Can nitrogen gas be heated? Leverage Inert Heat for Precision and Safety