At its core, ash content is a direct measure of the total amount of inorganic, non-combustible material within a substance. After a sample is completely burned under controlled conditions, the residue that remains—the "ash"—is weighed. This value is typically expressed as a percentage of the original sample's weight.

Ash content is not a measure of imperfection; it is a critical data point that reveals the quantity of mineral fillers, reinforcements, or inorganic impurities within a material. It serves as a fundamental indicator of composition, quality, and consistency.

What Ash Content Reveals About Composition

The ash value provides a clear window into the non-organic components of a material, which are often present by design.

Identifying Inorganic Fillers

Many materials, especially polymers, are not pure. They contain inorganic fillers to modify their properties.

Ash content directly quantifies the percentage of these additives, such as calcium carbonate, talc, or silica.

Quantifying Reinforcements

For high-strength applications, materials are often reinforced with inorganic substances.

The ash test is a simple way to verify the loading percentage of reinforcements like glass fibers or mineral fibers, which are crucial for achieving desired mechanical properties like stiffness and durability.

Detecting Impurities

In materials intended to be pure, any significant ash content can indicate contamination.

This is a red flag in quality control, suggesting the presence of unwanted inorganic residues from the manufacturing process or raw materials.

The Role of Ash Content in Quality Control

For manufacturers, ash content is less of an analytical curiosity and more of a critical process control tool.

Verifying Material Specifications

Products are designed with a specific percentage of filler or reinforcement to meet performance targets.

The ash test is the primary method used to confirm that a batch of material meets these exact specifications before it is used or shipped.

Ensuring Consistency

Consistency is the hallmark of quality manufacturing. Tracking the ash content from batch to batch is a powerful way to monitor process stability.

Deviations in the ash value can signal a problem in mixing ratios or raw material supply long before it affects the final product's performance.

Understanding the Limitations

While incredibly useful, the ash content value does not tell the whole story. It's essential to recognize its limitations.

It Is a Quantitative, Not Qualitative, Measure

The ash test tells you how much inorganic material is present, but it does not tell you what that material is.

For example, a 30% ash content could be 30% glass fiber as intended, or it could be 25% glass fiber and 5% unknown contamination. Further analysis, such as spectroscopy, is required for chemical identification.

Context Is Everything

A "good" or "bad" ash value is entirely dependent on the material's specification.

A 40% ash content is expected for a glass-filled nylon but would indicate massive contamination in a material that is supposed to be a pure polymer. The number is meaningless without its proper context.

Making the Right Choice for Your Goal

Your interpretation of an ash content value depends entirely on your objective.

- If your primary focus is quality assurance: Use ash content as a fast and reliable check to ensure incoming materials and outgoing products meet their specified filler percentages.

- If your primary focus is material development: Treat ash content as a key variable that directly influences physical properties like stiffness, strength, and density.

- If your primary focus is failure analysis: An unexpected ash content can be a critical clue, pointing toward material contamination or an incorrect formulation as the root cause of a problem.

Ultimately, understanding ash content empowers you to validate material composition and guarantee product performance.

Summary Table:

| Aspect | What Ash Content Reveals |

|---|---|

| Composition | Quantity of inorganic fillers (e.g., talc, calcium carbonate) and reinforcements (e.g., glass fibers). |

| Quality Control | Verifies material meets specifications and ensures batch-to-batch consistency. |

| Impurity Detection | Flags unwanted inorganic contamination in raw materials or final products. |

| Limitation | Measures quantity, not quality; identifies 'how much,' not 'what' the inorganic material is. |

Need precise ash content analysis to ensure your material quality and consistency? KINTEK specializes in providing reliable lab equipment and consumables for accurate testing. Our solutions help you verify filler percentages, detect impurities, and maintain strict quality control standards. Contact our experts today to find the right tools for your laboratory's needs!

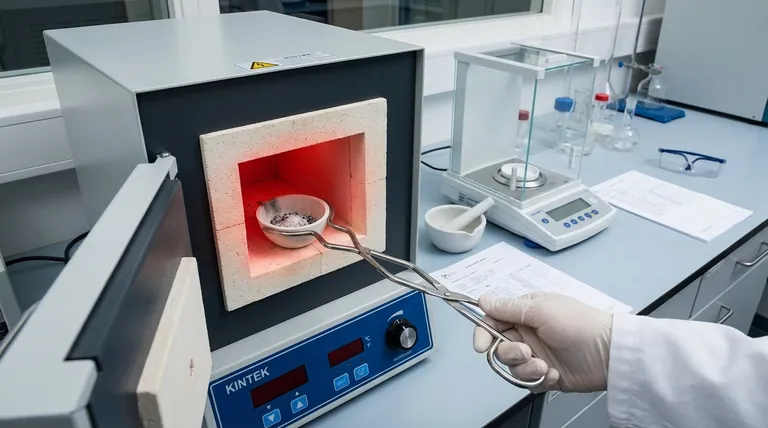

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the function of a laboratory oven in the pretreatment of cigarette filter waste? Preserving Cellulose Acetate

- What role does a high-temperature box-type resistance furnace play in the homogenization annealing of AFA steel?

- What is a laboratory oven? A Guide to Precision Heating for Scientific Applications

- What is the refractory material used in muffle furnace? Choose the Right Lining for Your Lab's Needs

- What is ashing in chemistry? Enhance Analytical Accuracy with Ashing Techniques

- How do I choose a heat treatment process? Select the Right Method for Your Metal Components

- What equipment is used to determine ash content? The Essential Muffle Furnace Guide

- How does a laboratory muffle furnace contribute to the generation of active metal oxide components? Optimize Catalysis