Ultimately, a furnace's power consumption is most directly influenced by its efficiency. While factors like size and age play a role, efficiency is the measure of how effectively the furnace converts energy input (like gas or electricity) into usable heat. The less energy wasted in this process, the lower the overall power consumption required to achieve a target temperature.

The core principle is simple: a furnace's energy consumption is not a fixed number. It is a dynamic outcome dictated by the unit's operational efficiency and the external conditions it must overcome.

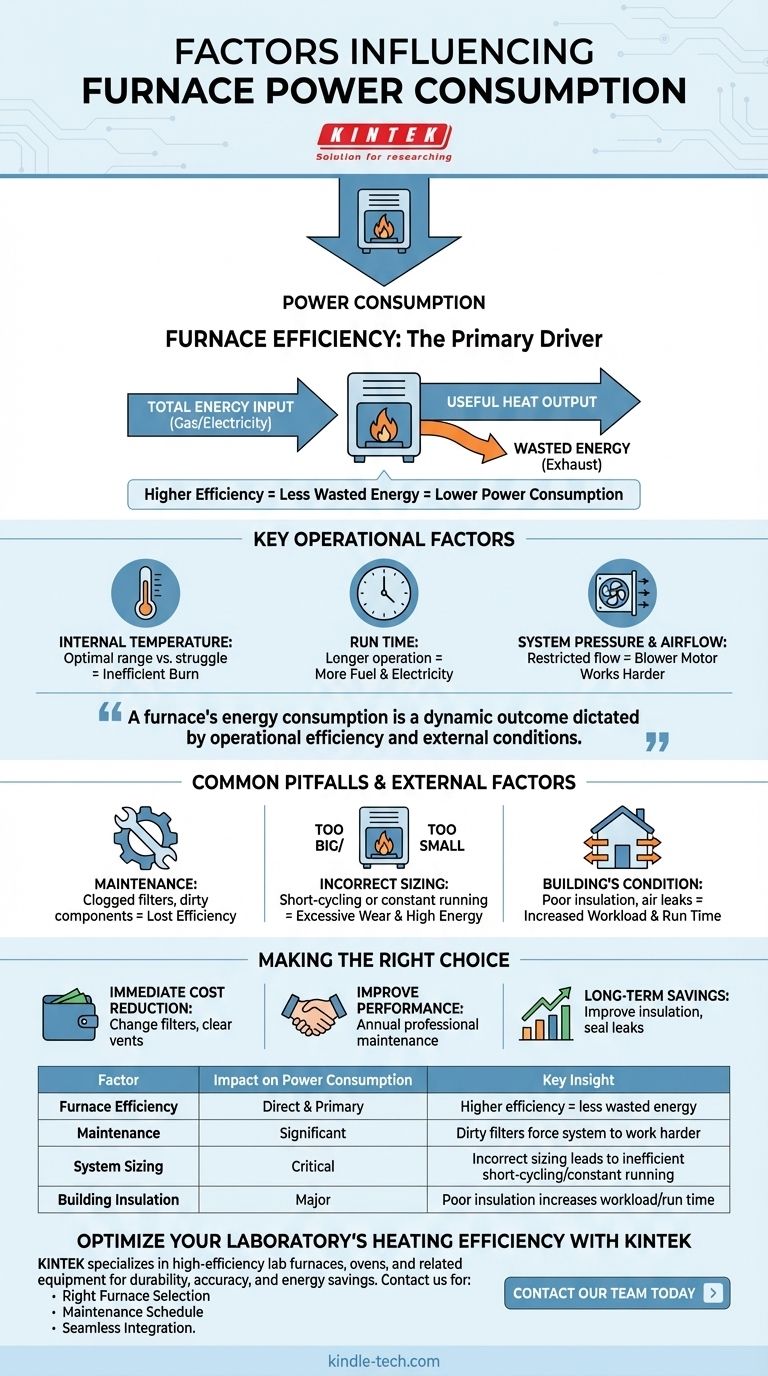

The Core Principle: Furnace Efficiency Explained

A furnace's job is to convert fuel into heat. How well it performs this conversion is the single most important factor determining how much power it uses over time.

What is Efficiency?

Efficiency is the ratio of a furnace's useful heat output to its total energy input. For example, a furnace with an 80% efficiency rating converts 80% of its fuel into heat for your space, while the remaining 20% is lost as exhaust.

A higher efficiency rating means less wasted energy.

How Inefficiency Drives Consumption

A low-efficiency unit must run longer or burn more fuel to produce the same amount of heat as a high-efficiency unit. This extended operation directly translates to higher electricity usage for components like the blower fan and higher fuel consumption.

Key Operational Factors Driving Consumption

Several core operational parameters influence a furnace's moment-to-moment efficiency and, therefore, its power consumption.

Internal Temperature

Every furnace is designed to operate within a specific temperature range for optimal performance. A system that struggles to reach or maintain this temperature due to internal issues will burn fuel inefficiently, increasing overall consumption.

Run Time

The total time the furnace must operate to heat a space is a primary driver of energy use. Longer run times mean more fuel and electricity are consumed. This is influenced by the furnace's heating capacity relative to the space's needs.

System Pressure & Airflow

For forced-air systems, the blower motor uses a significant amount of electricity. If airflow is restricted by dirty filters or blocked vents, the motor must work harder and draw more power to circulate air. This internal system pressure is critical for efficient operation.

Common Pitfalls and External Factors

A furnace does not operate in a vacuum. Its real-world performance is heavily impacted by maintenance and the environment it serves.

The Critical Role of Maintenance

Proper management and maintenance are essential for optimal performance. A furnace with clogged filters, dirty burners, or unlubricated motors will lose efficiency, forcing it to work harder and consume more power to do the same job.

Incorrect Sizing

A furnace that is too large for a space will heat it too quickly and turn off, a process called "short-cycling." This constant starting and stopping is highly inefficient. Conversely, an undersized unit will run constantly, leading to excessive wear and high energy bills.

The Building's Condition

The furnace's workload is determined by the building itself. Poor insulation, air leaks around windows and doors, and unsealed ducts force the furnace to run much more frequently to compensate for the constant heat loss, directly increasing power consumption.

Making the Right Choice for Your Goal

Understanding these factors allows you to take control of your furnace's energy usage.

- If your primary focus is immediate cost reduction: Regularly replace air filters and ensure all vents are clear to maintain proper airflow.

- If your primary focus is improving system performance: Schedule professional annual maintenance to ensure the furnace is clean, calibrated, and operating safely.

- If your primary focus is long-term energy savings: Invest in improving your building's insulation and sealing air leaks to reduce the furnace's overall workload.

By shifting your focus from the furnace alone to the entire heating system, you can achieve significant and lasting reductions in power consumption.

Summary Table:

| Factor | Impact on Power Consumption | Key Insight |

|---|---|---|

| Furnace Efficiency | Direct & Primary | Higher efficiency = less wasted energy and lower consumption. |

| Maintenance | Significant | Dirty filters or lack of tuning force the system to work harder. |

| System Sizing | Critical | An incorrectly sized furnace leads to inefficient short-cycling or constant running. |

| Building Insulation | Major | Poor insulation increases the furnace's workload and run time. |

Optimize Your Laboratory's Heating Efficiency with KINTEK

Is your lab furnace consuming more energy than it should? The factors outlined above are critical for maintaining precise temperature control and managing operational costs in a laboratory setting. KINTEK specializes in high-efficiency lab furnaces, ovens, and related equipment designed for durability, accuracy, and energy savings.

Our experts can help you:

- Select the right furnace for your specific application and space requirements.

- Implement a maintenance schedule to ensure peak performance and longevity.

- Integrate solutions that work seamlessly with your lab's environment.

Reduce your energy costs and improve your lab's performance. Contact our team today for a personalized consultation!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat Sintering Brazing Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- How to vacuum out a furnace? A Step-by-Step Guide to Safe DIY Maintenance

- What is vacuum heat treatment process? Achieve Superior Control, Cleanliness, and Quality

- What materials are used in a vacuum furnace? A Guide to Hot Zone Materials and Processed Metals

- Is heat Cannot travel in a vacuum True or false? Discover How Heat Crosses the Void of Space

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost