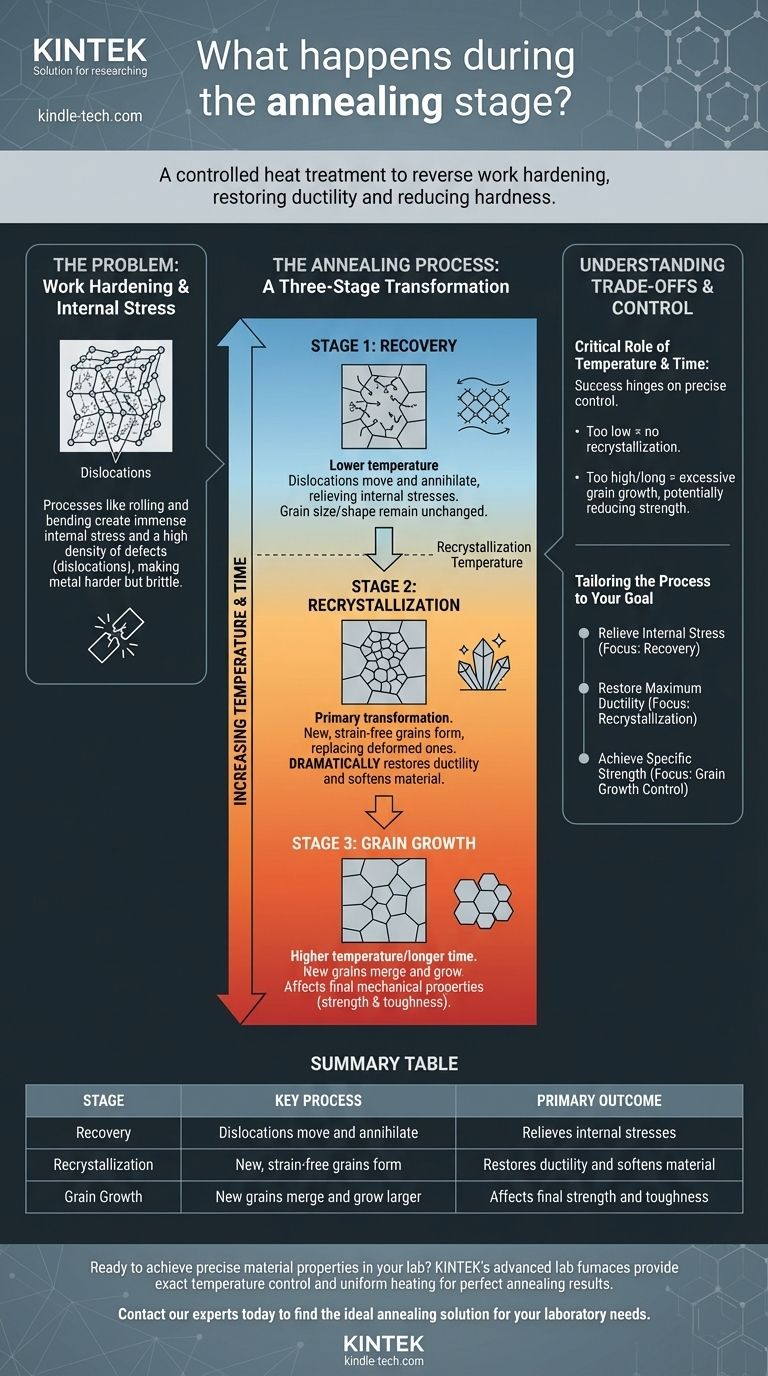

In essence, annealing is a controlled heat treatment designed to reverse the effects of work hardening in metals. It systematically restores a material's ductility and reduces its hardness by heating it above its recrystallization temperature, allowing its internal crystal structure to repair itself. This transformation happens across three distinct stages: recovery, recrystallization, and grain growth.

The fundamental purpose of annealing is to relieve internal stresses and repair the microscopic damage induced during fabrication processes. By using thermal energy, it resets the metal's grain structure, making it softer, more stable, and easier to work with.

The Problem: Why Annealing is Necessary

Before a metal is annealed, its internal structure is often in a state of high stress and disorder. Understanding this initial state is key to understanding why the process is so critical.

Internal Stress and Work Hardening

Processes like casting, rolling, or bending create immense stress within a metal's crystal lattice. This "work hardening" introduces a high density of defects, primarily linear ones called dislocations.

While this makes the metal harder, it also makes it more brittle and difficult to shape further without cracking. Annealing is the solution to this problem.

The Annealing Process: A Three-Stage Transformation

As the temperature of the metal is raised and held, its microstructure undergoes a predictable series of changes. Each stage addresses a different aspect of the internal damage.

Stage 1: Recovery

The recovery stage occurs at a lower temperature, before the primary transformation begins. During this phase, the metal begins to soften as the thermal energy allows dislocations to move and annihilate each other.

This process significantly relieves the internal stresses that were locked into the material. However, the overall size and shape of the metal's grains do not yet change.

Stage 2: Recrystallization

This is the heart of the annealing process. As the temperature rises above the material's specific recrystallization temperature, something profound happens.

Entirely new, strain-free grains begin to nucleate and grow. These new crystals consume and replace the old, deformed grains that were filled with dislocations. This is the primary mechanism that restores ductility and dramatically softens the material.

Stage 3: Grain Growth

If the metal is held at the annealing temperature after recrystallization is complete, the grain growth stage begins.

During this phase, the newly formed, strain-free grains start to merge and grow larger. This can be a desired or undesired outcome, as grain size has a significant impact on a material's final mechanical properties, such as strength and toughness.

Understanding the Trade-offs

Annealing is not simply a matter of heating and cooling. The process must be precisely controlled to achieve the desired outcome, as improper execution can lead to unintended consequences.

The Risk of Excessive Grain Growth

While recrystallization is essential, allowing grains to grow too large can sometimes be detrimental. Overly large grains can, in some materials, reduce strength and fracture toughness.

The Critical Role of Temperature and Time

The success of annealing hinges on two parameters: temperature and duration. If the temperature is too low, recrystallization will not occur. If it's too high or held for too long, excessive grain growth can compromise the material's final properties.

Matching the Process to Your Goal

By understanding the distinct stages, you can tailor the annealing process to meet specific engineering requirements.

- If your primary focus is relieving internal stress: A low-temperature treatment that focuses on the recovery stage may be sufficient, though a full anneal provides the most complete relief.

- If your primary focus is restoring maximum ductility for further forming: You must ensure the material fully passes through the recrystallization stage to create a new, workable grain structure.

- If your primary focus is achieving a specific mechanical strength: Careful control of temperature and time during the grain growth stage is critical to producing the precise grain size needed for your application.

Ultimately, mastering annealing means using heat to precisely manipulate a metal's internal architecture to achieve its intended performance.

Summary Table:

| Stage | Key Process | Primary Outcome |

|---|---|---|

| Recovery | Dislocations move and annihilate | Relieves internal stresses |

| Recrystallization | New, strain-free grains form | Restores ductility and softens material |

| Grain Growth | New grains merge and grow larger | Affects final strength and toughness |

Ready to achieve precise material properties in your lab?

KINTEK's advanced lab furnaces provide the exact temperature control and uniform heating required for perfect annealing results. Whether you're relieving stress or tailoring grain structure, our equipment ensures reliable and repeatable performance.

Contact our experts today to find the ideal annealing solution for your laboratory needs.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

People Also Ask

- What is the difference between upflow and horizontal furnace? Find the Perfect Fit for Your Home's Layout

- Why does heating increase temperature? Understanding the Molecular Dance of Energy Transfer

- How do you clean a tubular furnace tube? A Step-by-Step Guide to Safe and Effective Maintenance

- What is the temperature of a quartz tube furnace? Master the Limits for Safe, High-Temp Operation

- What is quartz tube heating? Achieve Instant, Targeted Heat with Infrared Radiation