Ultimately, a “good” mini heat press is a precision tool defined by its ability to deliver consistent, edge-to-edge heat safely and reliably. While models like the Cricut EasyPress Mini are a popular benchmark, the best choice is not about a brand but about specific features that solve the core problems a standard home iron cannot. A quality mini press provides the control needed for professional results on small or challenging surfaces.

A great mini heat press solves the problem of applying heat transfers to small, curved, or irregular items where a home iron fails and a traditional press is too cumbersome. Its value lies in precise temperature control and even heating, but its main trade-off is the reliance on manual, user-applied pressure.

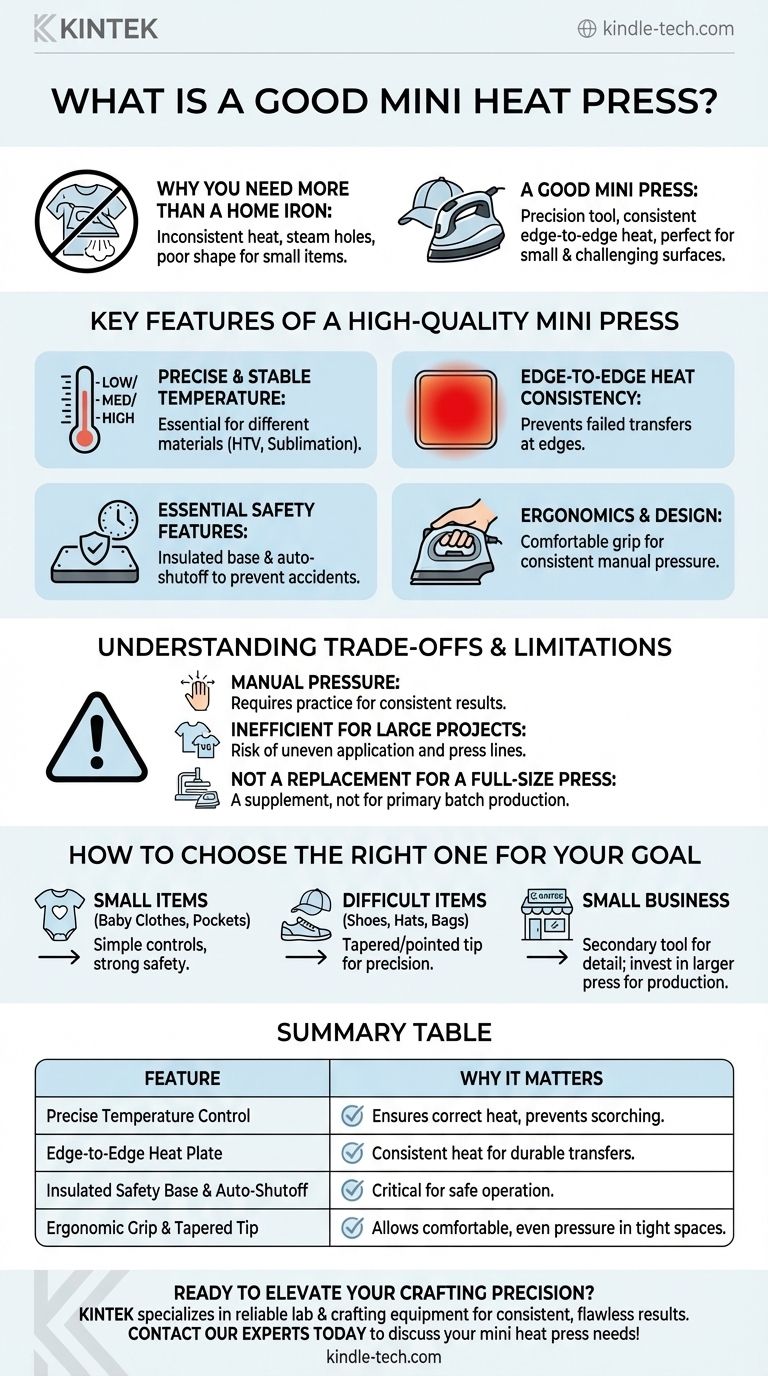

Why You Need More Than a Home Iron

For anyone serious about heat transfer crafts, moving beyond a standard household iron is a critical step. A dedicated mini press addresses the fundamental flaws of using a tool not designed for the job.

The Problem with Irons

A home iron is designed for removing wrinkles with steam and movement, not for static, even heat application. Its surface has holes for steam and suffers from significant temperature fluctuations, leading to inconsistent and peeling transfers.

Furthermore, an iron's shape is not suited for navigating around seams, buttons, or the curved surfaces of items like hats and shoes.

Where Mini Presses Excel

A mini heat press shines with projects that are small, awkwardly shaped, or require precision. Its compact, solid heat plate provides consistent thermal energy directly where you need it.

This makes it the ideal tool for personalizing shoes, stuffed animals, hats, baby bodysuits, and adding small logos or labels near seams on larger garments.

Portability and Convenience

Mini presses are lightweight, portable, and require minimal storage space. This makes them a perfect fit for hobbyists with limited room or those who need to take their crafting tools to different locations.

Key Features of a High-Quality Mini Heat Press

When evaluating a mini heat press, focus on the technical capabilities that directly impact the quality and safety of your work.

Precise and Stable Temperature

The most critical feature is the ability to set and hold a specific temperature. Look for models with multiple distinct heat settings (e.g., low, medium, high) that correspond to the needs of different materials like heat-transfer vinyl (HTV), Infusible Ink, or sublimation transfers.

Edge-to-Edge Heat Plate Consistency

A quality press uses a solid, ceramic-coated plate that distributes heat evenly across its entire surface. This ensures that every part of your design receives the correct temperature, preventing failed transfers at the edges.

Essential Safety Features

Working with high heat demands respect. A reliable mini press must include an insulated safety base to rest the hot tool on when not in use.

An auto-shutoff feature is another non-negotiable function, turning the press off after a period of inactivity to prevent accidents.

Ergonomics and Design

The press should feel comfortable and balanced in your hand. A well-designed ergonomic grip allows you to apply firm, even pressure without straining your wrist, which is crucial for achieving a durable bond.

Understanding the Trade-offs and Limitations

While incredibly useful, a mini heat press is a specialized tool with clear limitations. Understanding these is key to avoiding frustration.

The Challenge of Manual Pressure

Unlike a clamshell or swing-away press that locks down, a mini press relies entirely on you to provide consistent pressure. This is a skill that requires practice. Applying too little pressure, or applying it unevenly, is the most common cause of failed transfers.

Inefficiency for Larger Projects

Using a mini press for a large design is not recommended. It requires you to press the area in multiple overlapping sections, which dramatically increases the risk of uneven application, visible press lines, or scorching the material.

Not a Replacement for a Full-Size Press

If you plan to produce items in batches or frequently work with full-front T-shirt designs, a mini press is not the right primary tool. It is a supplement to a larger press, not a substitute for one.

How to Choose the Right Mini Press for Your Goal

Your specific projects should guide your choice. Match the tool to your most common tasks.

- If your primary focus is crafting with HTV on small items (e.g., baby clothes, pockets): Prioritize a model with simple controls and strong safety features, as this will cover the majority of your needs.

- If your primary focus is personalizing difficult items (e.g., shoes, hats, structured bags): Look for a press with a tapered or pointed tip for maximum precision and the ability to get into tight corners.

- If your primary focus is starting a small business: View a mini press as a secondary tool for customization and detail work, but invest in at least a small (9"x9" or larger) traditional press for your primary production.

Choosing the right tool empowers you to execute your creative vision with precision and consistency.

Summary Table:

| Feature | Why It Matters |

|---|---|

| Precise Temperature Control | Ensures correct heat for different materials (HTV, sublimation), preventing scorching or peeling. |

| Edge-to-Edge Heat Plate | Provides consistent heat across the entire design for professional, durable transfers. |

| Insulated Safety Base & Auto-Shutoff | Critical for safe operation, preventing accidents and burns. |

| Ergonomic Grip & Tapered Tip | Allows for comfortable, even pressure and access to tight spaces like hats and shoes. |

Ready to Elevate Your Crafting Precision?

A high-quality mini heat press is the key to unlocking professional-grade results on small, curved, or intricate items. Whether you're personalizing shoes, baby clothes, or adding detailed logos, the right tool makes all the difference.

KINTEK specializes in reliable lab and crafting equipment, helping you achieve consistent, flawless results. Our expertise ensures you get the precise control and safety features you need for your projects.

Let us help you find the perfect tool for your creative vision. Contact our experts today to discuss your mini heat press needs!

Visual Guide

Related Products

- Automatic Laboratory Heat Press Machine

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Infrared Heating Quantitative Flat Plate Press Mold

People Also Ask

- What are the advantages of using a hot press for Li7P2S8I0.5Cl0.5? Boost Conductivity with Precision Densification

- What role does a hot press play in treating the CAL-GPE interface? Optimize Performance for Flexible Lithium Batteries

- Why is a laboratory hot press required for Oxygen Depolarized Cathodes? Ensure Precision Molding and Conductivity.

- How is pressure generated and applied in a hot press? Master High-Intensity Hydraulic & Pneumatic Systems

- What is a hydraulic floor press used for? A Versatile Tool for Industrial and Lab Applications