At its core, a workshop press is a tool designed to apply a massive, controlled amount of force to a small area. It uses hydraulic or mechanical leverage to perform tasks that would be impossible with manual strength, such as installing or removing press-fit bearings, bending thick metal, or straightening bent shafts. It is a cornerstone piece of equipment in automotive repair, metal fabrication, and general maintenance shops.

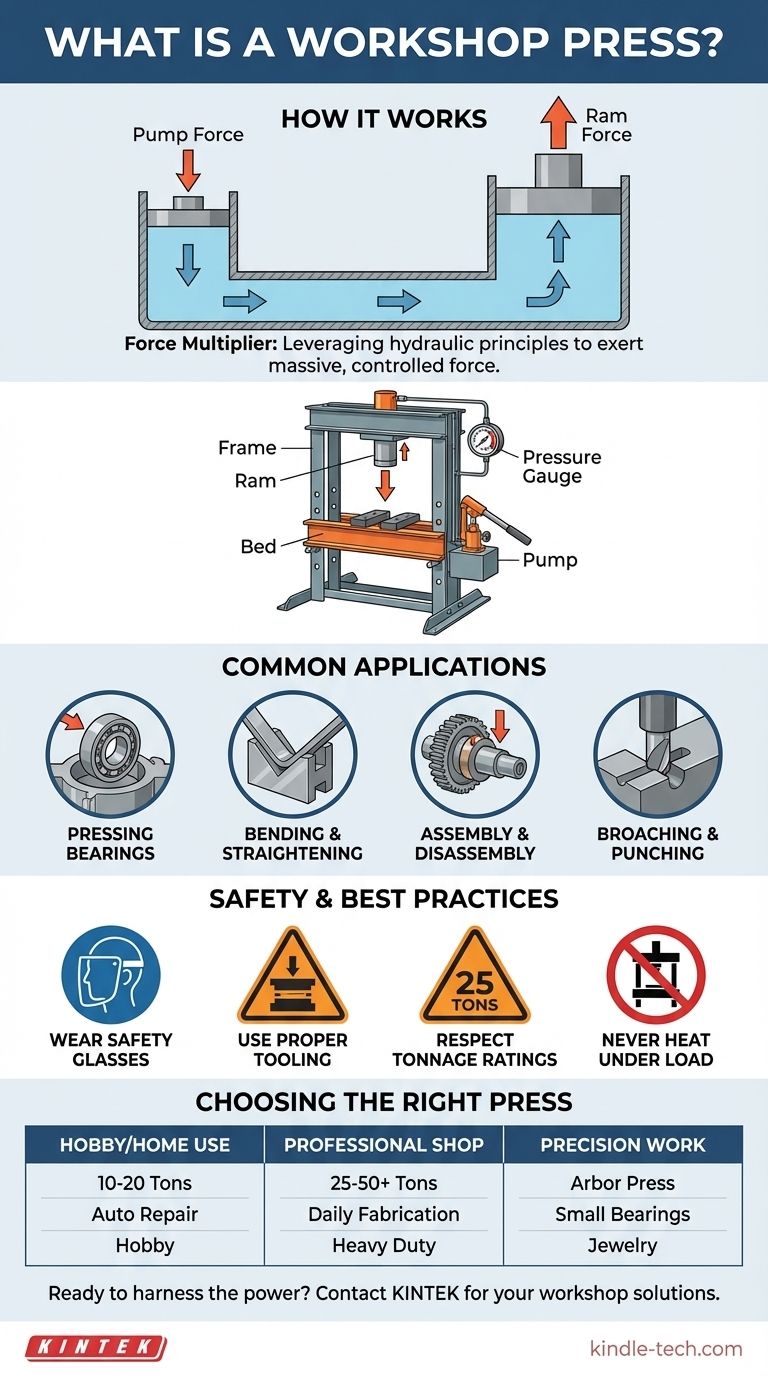

A workshop press is not just a tool; it's a force multiplier. By leveraging hydraulic principles, it allows a single operator to exert tons of controlled force for pressing, bending, and assembling components with high precision and safety.

How a Workshop Press Works

Understanding a press begins with understanding the source of its power. While some simple presses use mechanical screws or levers, the vast majority of modern workshop presses are hydraulic.

The Principle of Hydraulic Force

A hydraulic press operates on Pascal's Law, which states that pressure applied to a confined fluid is transmitted undiminished throughout the fluid.

The system uses two pistons in a sealed cylinder filled with oil. An operator pumps a handle (or uses a powered pump) to apply a small amount of force to a small piston. This creates pressure in the hydraulic fluid, which then acts on a much larger piston (the ram), multiplying the initial force immensely.

Key Components of a Hydraulic Press

A typical press consists of several distinct parts working in concert:

- Frame: The main structure, usually an "H-Frame" or "A-Frame," that withstands the immense opposing forces generated during operation.

- Ram: The large, movable piston that is forced downward to apply pressure to the workpiece.

- Pump: A manual hand pump or a powered (air or electric) hydraulic pump that creates the fluid pressure.

- Pressure Gauge: A critical safety and precision component that shows the operator exactly how much force is being applied, usually measured in tons.

- Bed: The adjustable cross-member or table that supports the workpiece. Its height can be changed to accommodate objects of different sizes.

Common Applications in the Workshop

A press is a versatile tool, but its applications all center around the controlled application of linear force.

Pressing Bearings and Bushings

This is arguably the most common use. A press provides the steady, even pressure required to push bearings or suspension bushings into or out of their housings without damaging the component or the housing itself.

Bending and Straightening Metal

With the use of V-blocks and other accessories, a press can be used to create clean, precise bends in flat bar, round stock, or other metal profiles. It is also invaluable for straightening parts, such as a bent axle or tie rod, that have been deformed in use.

Assembly and Disassembly

The press is essential for assembling components that have an interference fit, such as pressing a gear onto a motor shaft. It is equally useful for separating such parts, applying the force needed to overcome the tight fit.

Broaching and Punching

With specialized tooling, a press can be used to cut keyways into hubs (broaching) or to punch holes through metal plates. This allows for precise shaping that would be difficult with other methods.

Understanding the Trade-offs and Safety Considerations

While incredibly useful, the power of a workshop press demands respect and a clear understanding of its risks.

The Dangers of Extreme Force

The forces involved are enormous. A component that is not properly supported or has a hidden flaw can shatter under load, sending shrapnel across the workshop at high speed. Always wear safety glasses and use a guard if possible.

The Need for Proper Tooling

The press itself is only half the equation. You must use appropriate press plates, blocks, and arbors to support the workpiece correctly and distribute force evenly. Using sockets, random scraps of steel, or other improper supports is a common cause of accidents and damaged parts.

Tonnage Ratings Matter

Presses are rated by the maximum force they can generate, such as a "20-ton press." Using a press that is underrated for a job will fail to accomplish the task, while using one that is grossly overrated can make it difficult to feel and control the pressure, increasing the risk of damaging the part.

Never Heat and Press Simultaneously

Never apply a torch to a part while it is under pressure in the press. The combination of thermal stress and physical load can lead to an explosive, catastrophic failure of the component. Heat parts separately before placing them in the press if thermal expansion is needed.

Making the Right Choice for Your Needs

The right press depends entirely on the scale and frequency of your work.

- If your primary focus is home auto repair or hobby fabrication: A 10 to 20-ton H-frame hydraulic press is versatile and powerful enough for most tasks like wheel bearings, U-joints, and suspension bushings.

- If you run a professional fabrication or heavy-duty repair shop: A 25 to 50-ton press with a powered pump and a movable ram head provides the efficiency and power needed for daily, demanding work.

- If your work involves only small-scale precision tasks: A simple, bench-mounted mechanical arbor press is an excellent, low-cost option for small bearings, pins, and jewelry making.

Ultimately, a workshop press transforms tasks that seem impossible into routine, controlled procedures, giving you precise command over immense force.

Summary Table:

| Aspect | Key Details |

|---|---|

| Primary Function | Applies controlled, massive force for pressing, bending, and straightening. |

| Common Types | Hydraulic (H-Frame/A-Frame) and Mechanical (Arbor Press). |

| Typical Applications | Installing/removing bearings & bushings, bending metal, straightening shafts, assembly/disassembly. |

| Key Safety Considerations | Always wear safety glasses, use proper tooling (press plates/blocks), and never heat a part under pressure. |

| Tonnage Guide | Hobby/Home Use: 10-20 tons. Professional Shop: 25-50+ tons. Precision Work: Bench-mounted arbor press. |

Ready to harness the power of a workshop press in your lab or workshop?

KINTEK specializes in providing robust and reliable lab equipment, including workshop presses perfect for your maintenance, fabrication, or R&D needs. Whether you're in automotive repair, metalworking, or general lab maintenance, our equipment ensures precision, safety, and durability.

Contact us today to find the perfect press for your application and experience the KINTEK difference in quality and support!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy