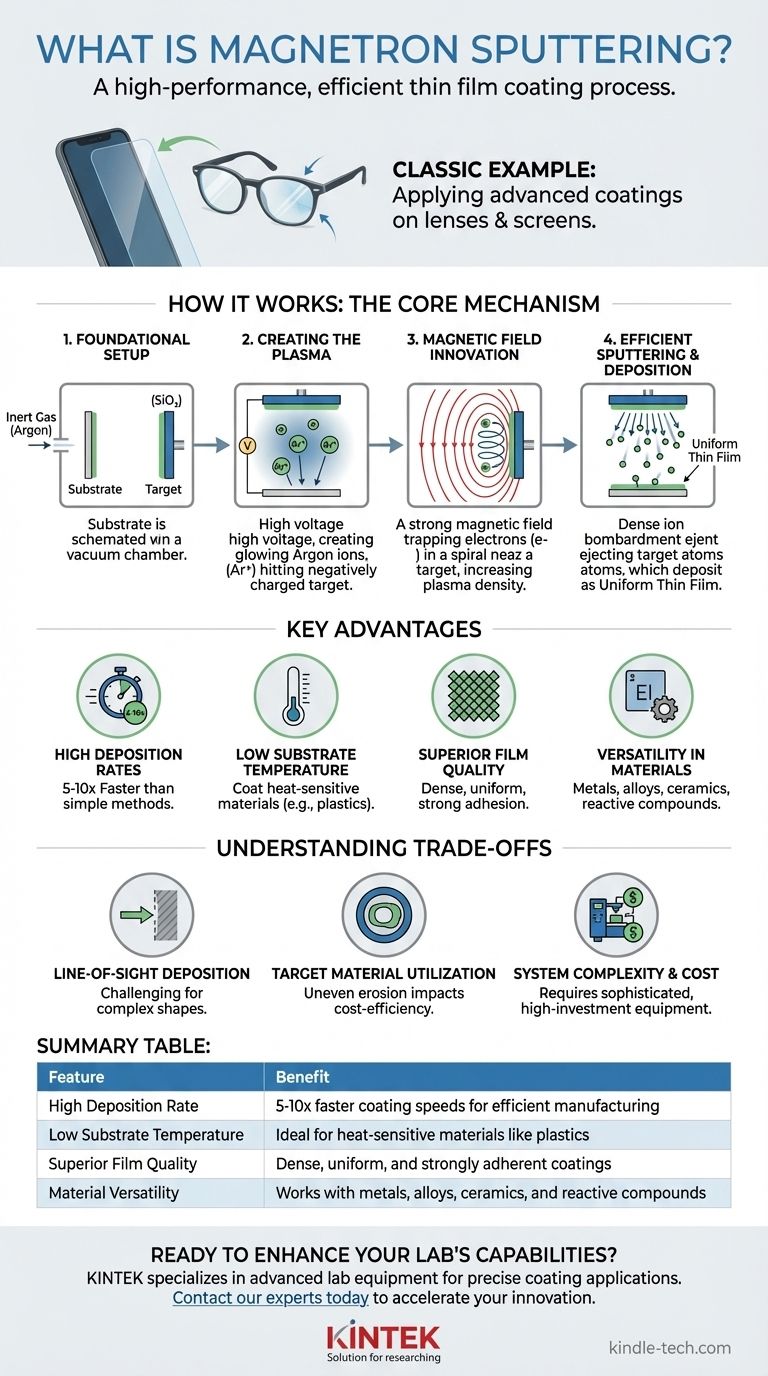

A classic example of magnetron sputtering is the application of an anti-reflective and scratch-resistant coating on eyeglass lenses or smartphone screens. In this process, a target made of a material like silicon dioxide is bombarded with ions in a vacuum chamber. The magnetic field concentrates this bombardment, efficiently ejecting microscopic particles of the material, which then deposit as a perfectly uniform, ultra-thin film onto the surface of the lens or glass.

Magnetron sputtering is not just a method for coating a surface; it is a highly controlled and efficient engineering process. It uses a magnetic field to intensify the plasma used for deposition, resulting in faster, denser, and higher-quality thin films at lower temperatures than other methods.

How Magnetron Sputtering Works

To understand its value, it's essential to grasp the core mechanism that sets magnetron sputtering apart from other deposition techniques. The process elegantly solves the speed and efficiency problems of earlier methods.

The Foundational Setup

The process begins in a vacuum chamber containing the object to be coated (the substrate) and a block of the coating material (the target). A small amount of an inert gas, typically Argon, is introduced into the chamber.

Creating the Plasma

A high voltage is applied to the target, making it a negative electrode (cathode). This electric field ionizes the Argon gas, stripping electrons from the Argon atoms and creating a glowing, energized mixture of ions and electrons known as a plasma. The positively charged Argon ions are then accelerated violently toward the negatively charged target.

The Magnetic Field: A Critical Innovation

This is the "magnetron" part. A powerful magnetic field is established parallel to the target's surface. This field acts like a magnetic trap for the lightweight electrons in the plasma, forcing them into a spiral path near the target instead of letting them escape.

The Result: Highly Efficient Sputtering

Trapping the electrons dramatically increases their density near the target. This dense cloud of electrons collides with and ionizes many more Argon atoms, creating a significantly denser, more intense plasma. This leads to a massive increase in the number of Argon ions bombarding the target, which in turn ejects—or "sputters"—target atoms at a much higher rate. These sputtered atoms travel and deposit onto the substrate as a thin film.

Key Advantages of the Process

The unique use of a magnetic field gives magnetron sputtering several distinct advantages that make it a go-to choice for high-performance coatings.

High Deposition Rates

By creating a denser plasma, magnetron sputtering achieves coating speeds that are 5 to 10 times faster than simple diode sputtering. This makes it ideal for industrial-scale manufacturing.

Low Substrate Temperature

The process is remarkably efficient, meaning less energy is wasted as heat transferred to the substrate. This allows for the coating of heat-sensitive materials, such as plastics and polymers, without causing damage or deformation.

Superior Film Quality

The high-energy arrival of sputtered atoms results in films that are exceptionally dense, uniform, and have strong adhesion to the substrate. This is critical for protective and optical coatings where performance is paramount.

Versatility in Materials

Virtually any metal, alloy, or ceramic can be made into a target and sputtered. Furthermore, by introducing reactive gases like nitrogen or oxygen into the chamber, compound films like titanium nitride (a hard coating) or indium tin oxide (a transparent conductor) can be created.

Understanding the Trade-offs

No process is perfect. Being a trusted advisor means acknowledging the practical limitations of a technology.

Line-of-Sight Deposition

Sputtering is a physical, line-of-sight process. Atoms travel in a relatively straight line from the target to the substrate. This can make it challenging to achieve a uniform coating on objects with complex shapes, deep trenches, or shadowed areas.

Target Material Utilization

The magnetic field that traps electrons also confines the most intense ion bombardment to a specific region on the target, often called a "racetrack." This leads to uneven erosion of the target material, meaning a significant portion may be unused, impacting cost-efficiency.

System Complexity and Cost

Magnetron sputtering systems require sophisticated vacuum chambers, high-voltage power supplies, and powerful magnet arrays. The initial capital investment and maintenance for such equipment can be substantial compared to simpler coating methods.

How to Apply This Knowledge

Understanding these principles allows you to identify when magnetron sputtering is the right tool for the job.

- If your primary focus is high-volume manufacturing of uniform coatings: The high deposition rate and excellent uniformity of magnetron sputtering are its defining advantages.

- If your primary focus is coating heat-sensitive materials like plastics: The characteristic low-temperature operation makes this one of the few viable high-performance coating methods.

- If your primary focus is creating high-purity, dense films for advanced applications: The control and quality afforded by the sputtering process are essential for semiconductors, optics, and medical devices.

Ultimately, magnetron sputtering provides a powerful solution for creating high-performance thin films that are integral to the technology we use every day.

Summary Table:

| Feature | Benefit |

|---|---|

| High Deposition Rate | 5-10x faster coating speeds for efficient manufacturing |

| Low Substrate Temperature | Ideal for heat-sensitive materials like plastics |

| Superior Film Quality | Dense, uniform, and strongly adherent coatings |

| Material Versatility | Works with metals, alloys, ceramics, and reactive compounds |

Ready to enhance your lab's capabilities with high-performance thin films? KINTEK specializes in advanced lab equipment and consumables for precise coating applications. Whether you're developing optical coatings, protective layers, or electronic components, our solutions deliver the uniformity and quality your research demands. Contact our experts today to discuss how our magnetron sputtering systems can accelerate your innovation.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Molybdenum Vacuum Heat Treat Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- What temperature range can an Ultra Freezer operate at? Essential Guide to ULT Freezer Performance

- What is the process of thin film formation? A Guide to Atomic-Level Surface Engineering

- Which type of material is used in hot forging? Choosing the Right Metal for Strength and Performance

- What is RF or DC sputtering? Choose the Right Thin Film Deposition Method

- What are the applications of radioactivity in industry? Enhancing Quality, Safety, and Efficiency

- How much does biomass cost compared to other energy sources? A Guide to Costs, Trade-offs, and Value

- What is the composition of an evaporator? The 3 Essential Components for Efficient Evaporation

- What is the purpose of a laboratory furnace? Achieve Precise High-Temperature Processing