Brazing is a metal-joining process that uses a filler metal with a lower melting point than the base metals being joined. From a safety perspective, it is a high-hazard operation requiring strict controls for toxic fumes, fire, high-pressure gases, and chemical exposure.

The most critical aspect of brazing safety is not just managing the visible flame and heat, but controlling the invisible and often highly toxic fumes generated from the filler metal, base metal coatings, and flux.

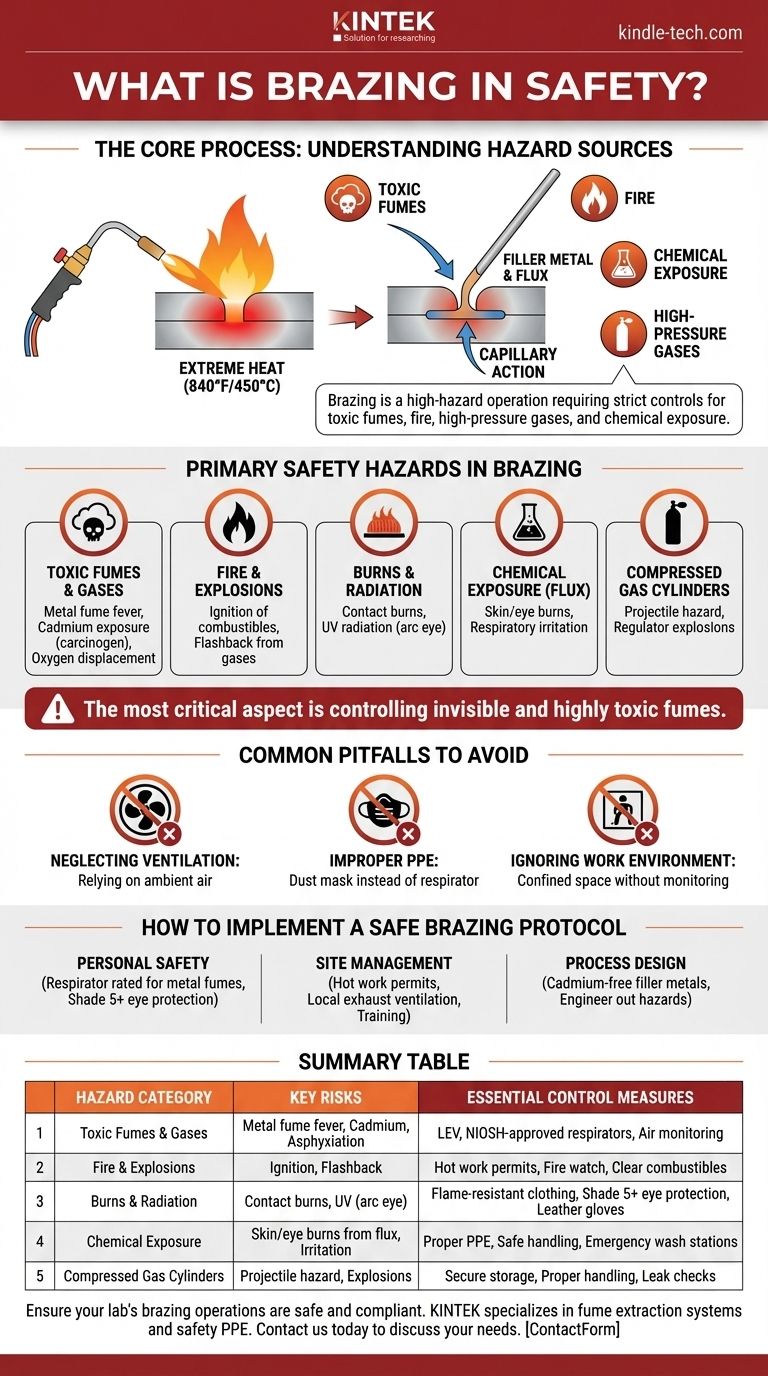

The Core Process: Understanding Hazard Sources

Brazing creates a strong, permanent bond between metal parts without melting them. Understanding how it works is key to identifying the points where hazards are introduced into the environment.

What is Brazing?

The process involves heating two or more closely fitted metal parts to a temperature above 840°F (450°C). A filler metal is then introduced, which is drawn into the gap between the parts by capillary action, creating a solid metallurgical bond upon cooling.

This use of extreme heat, specialized gases, and chemical agents is the foundation of all associated safety risks.

The Role of High Heat

The heat, typically from an oxy-fuel torch, is the most obvious hazard. It not only melts the filler metal but can also ignite any combustible materials in the work area.

The workpiece itself remains dangerously hot long after the flame is removed, presenting a significant burn risk.

The Filler Metal and Flux

The filler metal and the chemical flux are the primary sources of airborne hazards. When heated, these materials vaporize and release fumes.

Fillers may contain toxic metals like cadmium, zinc, or lead. Fluxes often contain fluorides, which can be highly irritating or toxic when inhaled.

Primary Safety Hazards in Brazing

A comprehensive safety plan must address several distinct categories of risk, each with its own control measures. The failure to manage any one of these can lead to serious injury or long-term health effects.

Toxic Fumes and Gases

This is the most insidious hazard. Inhaling metal fumes can cause "metal fume fever," an acute flu-like illness.

Long-term exposure to fumes from filler metals containing cadmium is extremely dangerous, as it is a known carcinogen and can cause severe kidney and lung damage.

Gases like nitrogen, often used to purge tubing, can displace oxygen in enclosed areas, creating a deadly asphyxiation hazard with no warning signs.

Fire and Explosions

The combination of a high-temperature open flame and flammable gases like acetylene presents a constant fire risk.

Work areas must be completely cleared of combustible materials like wood, paper, and flammable liquids. A hot work permit and a dedicated fire watch are often required by safety regulations.

Burns and Radiation

Contact burns from the flame, torch tip, or hot workpiece are common and severe. The intense flame also emits ultraviolet (UV) radiation, which can cause "arc eye" or "welder's flash," a painful burn to the cornea.

Chemical Exposure from Flux

Brazing flux is corrosive. Direct contact can cause chemical burns to the skin and eyes. Fumes from the flux are also a significant respiratory irritant.

Compressed Gas Cylinder Dangers

The fuel and oxygen cylinders are under immense pressure. If a cylinder is damaged or a valve is knocked off, it can become a projectile. Improper setup can also lead to flashback, where the flame travels back into the hoses and regulator, potentially causing an explosion.

Common Pitfalls to Avoid

Even experienced technicians can become complacent. Trusting that a job is "quick" or "minor" often leads to overlooking fundamental safety protocols with serious consequences.

Neglecting Ventilation

Relying on ambient air movement is a critical mistake. Adequate ventilation is non-negotiable. This means using local exhaust ventilation (LEV) systems that capture fumes at the source or working in a well-ventilated open area.

Improper Personal Protective Equipment (PPE)

Using the wrong PPE is as bad as using none at all. A simple dust mask offers zero protection against toxic metal fumes. A NIOSH-approved respirator with the correct cartridges is required.

Proper PPE for brazing includes a respirator, flame-resistant clothing, leather gloves, and shade 5 or higher eye protection.

Ignoring the Work Environment

Failing to assess the workspace is a recipe for disaster. Brazing in a confined space without proper air monitoring and ventilation can be fatal due to fume buildup or oxygen displacement.

How to Implement a Safe Brazing Protocol

Your safety strategy should be proactive, focusing on eliminating hazards before work begins.

- If your primary focus is personal safety: Always prioritize respiratory protection and ensure you are using a respirator rated for metal fumes, not just dust.

- If your primary focus is site management: Mandate the use of hot work permits, ensure local exhaust ventilation is in place and functioning, and verify technician training is current.

- If your primary focus is process design: Specify the use of cadmium-free filler metals wherever possible to engineer out the most severe fume hazard from the start.

Ultimately, a safe brazing operation is built on a consistent and unwavering commitment to managing every known risk.

Summary Table:

| Hazard Category | Key Risks | Essential Control Measures |

|---|---|---|

| Toxic Fumes & Gases | Metal fume fever, cadmium exposure, oxygen displacement | Local exhaust ventilation, NIOSH-approved respirators, air monitoring |

| Fire & Explosions | Ignition of combustibles, flashback from gases | Hot work permits, fire watch, clear work area of flammables |

| Burns & Radiation | Contact burns, UV radiation (arc eye) | Flame-resistant clothing, shade 5+ eye protection, leather gloves |

| Chemical Exposure | Skin/eye burns from flux, respiratory irritation | Proper PPE, safe handling procedures, emergency wash stations |

| Compressed Gas Cylinders | Projectile hazard, regulator explosions | Secure storage, proper handling, leak checks |

Ensure your lab's brazing operations are safe and compliant. KINTEK specializes in providing laboratory equipment and consumables, including fume extraction systems and safety PPE designed to protect your team from brazing hazards. Our experts can help you select the right safety solutions tailored to your specific laboratory needs. Contact us today to discuss how we can enhance your lab's safety protocols and protect your personnel.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

People Also Ask

- Where is cold-rolled steel used? Applications from Automotive to Appliances

- What is the energy efficiency of pyrolysis? It's a System, Not a Single Number

- What is the history of magnetron sputtering? The 1974 Breakthrough That Revolutionized Thin-Film Coating

- Where are evaporators used in food industry? Concentrate Products & Reduce Costs

- How does rotary vacuum evaporator work? Gentle, Efficient Solvent Removal Explained

- How does carburizing work? Achieve Superior Surface Hardness and Core Toughness

- What affects the rate of melting? Master the Key Factors for Precise Control

- Which torch brazing has a high production rate, reduced costs, and uniform quality? Discover Automated Torch Brazing