In essence, atmospheric pressure chemical vapor deposition (APCVD) is a method for creating thin, solid films on a surface by using chemical reactions from gases at standard air pressure. Unlike more common forms of chemical vapor deposition (CVD) that require a costly and complex vacuum, APCVD operates in a simpler chamber open to the atmosphere or filled with an inert gas, making the process faster and more economical.

The central takeaway is that APCVD intentionally trades the ultra-high purity and precision of vacuum-based CVD for significantly higher deposition speeds and lower equipment costs. It is a choice driven by the need for high-throughput manufacturing where absolute perfection is secondary to efficiency.

The Fundamental CVD Process

What is Chemical Vapor Deposition?

Chemical vapor deposition (CVD) is a foundational technique in materials science and manufacturing. It involves placing a target object, known as a substrate, inside a reaction chamber.

One or more volatile gases, called precursors, are then introduced into the chamber. These precursors react or decompose on the hot substrate surface, leaving behind a solid material deposit—the thin film.

The Purpose of a Thin Film

This process is used to deposit a wide variety of materials, including semiconductors, ceramics, and metals. These films can provide protective coatings against wear and corrosion, create photovoltaic layers for solar cells, or build the microscopic structures found in modern electronics.

The Critical Difference: Pressure's Role in Deposition

While all CVD processes share the same basic principle, the pressure inside the reaction chamber fundamentally changes the equipment, the process, and the final quality of the film.

Why Most CVD Uses a Vacuum

Many high-precision applications, especially in the semiconductor industry, use Low-Pressure CVD (LPCVD) or Ultra-High Vacuum CVD (UHV-CVD).

Operating in a vacuum removes atmospheric contaminants like oxygen and nitrogen, which could otherwise become trapped in the film and degrade its performance. Lower pressure also increases the "mean free path" of gas molecules, allowing them to coat complex, three-dimensional surfaces more uniformly.

How Atmospheric Pressure CVD (APCVD) Works

APCVD eliminates the need for expensive vacuum pumps and complex, sealed chambers. The process can often be run continuously, with substrates moving through the reaction zone on a conveyor belt, rather than being processed in discrete batches.

This operational simplicity and high throughput are the primary reasons for its use. Precursor gases are introduced into the chamber, typically carried by a high flow of an inert gas like nitrogen or argon, to displace the surrounding air and drive the reaction.

Understanding the Trade-offs: APCVD vs. Vacuum CVD

Choosing APCVD over a vacuum-based method is a deliberate engineering decision based on a clear set of trade-offs between cost, speed, and quality.

Advantage: Speed and Throughput

The most significant advantage of APCVD is its high deposition rate. Because there is a higher concentration of precursor molecules available at atmospheric pressure, films grow much faster than in a vacuum. This is ideal for industrial-scale production.

Advantage: Lower Cost and Simplicity

By avoiding the need for a vacuum, the equipment for APCVD is substantially cheaper, simpler to operate, and easier to maintain. This lowers the barrier to entry and reduces overall manufacturing costs.

Disadvantage: Film Purity and Contamination

The primary drawback is the risk of contamination. It is very difficult to completely eliminate ambient air (oxygen, water vapor) from an atmospheric pressure system. This can lead to the unintentional incorporation of impurities into the film, which is unacceptable for high-performance microelectronics.

Disadvantage: Poor Uniformity on Complex Shapes

At atmospheric pressure, precursor gases are more likely to react in the gas phase before reaching the substrate, which can form tiny particles that rain down and create a non-uniform film. The process is also diffusion-limited, making it difficult to coat intricate trenches or complex topographies evenly.

Making the Right Choice for Your Goal

Your application's specific requirements for purity, uniformity, and cost will determine whether APCVD is the appropriate method.

- If your primary focus is producing high-purity microelectronics (e.g., CPU transistors): You need the pristine, highly uniform films produced by vacuum-based CVD methods like LPCVD.

- If your primary focus is low-cost, large-area coating (e.g., protective layers on glass or solar cells): The high speed and economic efficiency of APCVD make it the superior choice, as minor impurities are often tolerable.

- If your primary focus is coating complex 3D parts uniformly: A vacuum-based process is necessary to ensure the precursor gases can reach and evenly coat all surfaces.

Ultimately, selecting the right deposition technique requires a clear understanding of the trade-off between the perfection achievable in a vacuum and the efficiency gained by operating at atmospheric pressure.

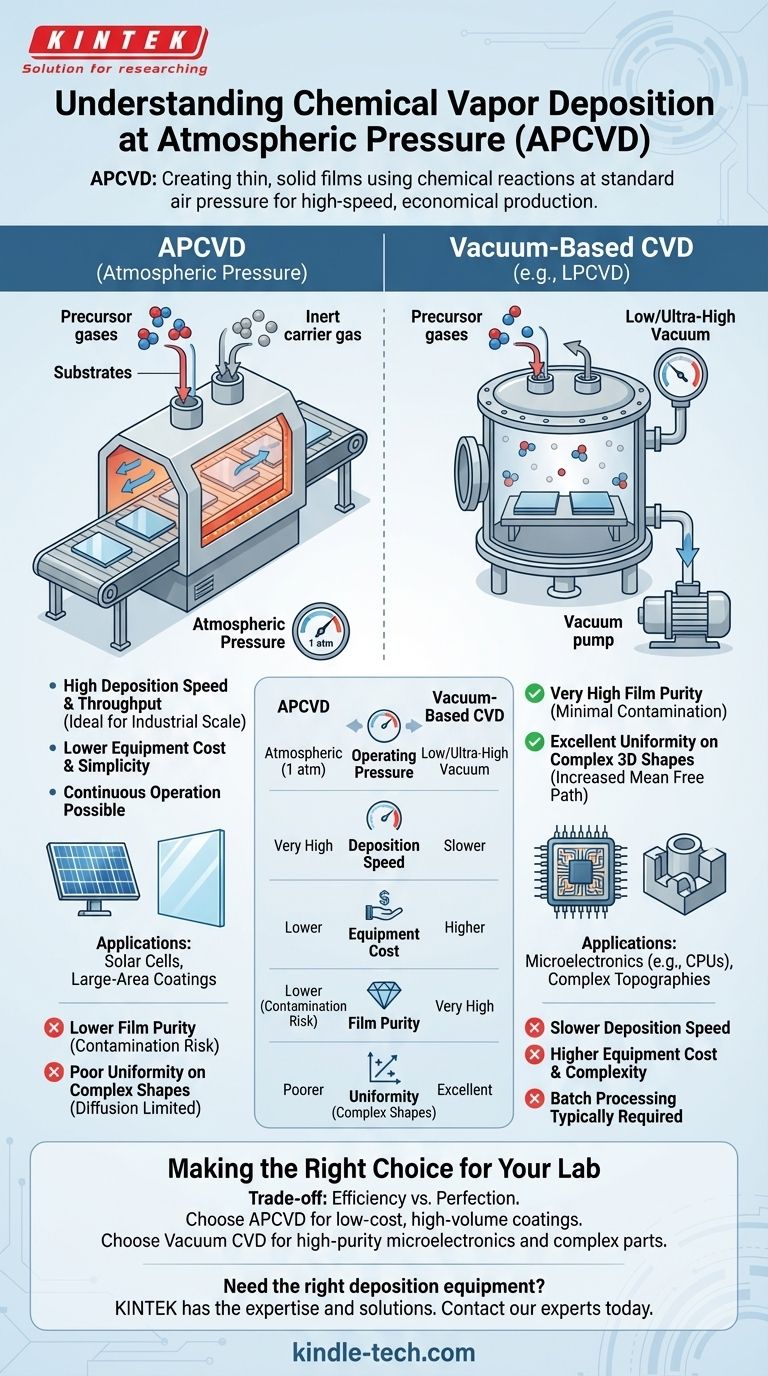

Summary Table:

| Aspect | APCVD | Vacuum-Based CVD (e.g., LPCVD) |

|---|---|---|

| Operating Pressure | Atmospheric Pressure | Low or Ultra-High Vacuum |

| Deposition Speed | Very High | Slower |

| Equipment Cost | Lower | Higher |

| Film Purity | Lower (risk of contamination) | Very High |

| Uniformity on Complex Shapes | Poorer | Excellent |

| Ideal For | High-throughput industrial coatings, solar cells | High-purity microelectronics, complex 3D parts |

Need the right deposition equipment for your lab's specific goals?

Whether your priority is the high-throughput efficiency of APCVD or the ultra-pure results of vacuum-based systems, KINTEK has the expertise and equipment to meet your laboratory's thin film deposition needs. Our range of CVD solutions is designed to help you achieve optimal performance and cost-effectiveness.

Contact our experts today to discuss your project and find the perfect solution for your research or production.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- How does PACVD equipment improve DLC coatings? Unlock Low Friction and High Heat Resistance

- What is the role of the HF-CVD system in preparing BDD electrodes? Scalable Solutions for Boron-Doped Diamond Production

- What are the advantages of using HFCVD for BDD electrodes? Scaling Industrial Diamond Production Efficiently

- What is the specific function of the metal filament in HF-CVD? Key Roles in Diamond Growth

- What is the hot filament chemical vapour deposition of diamond? A Guide to Synthetic Diamond Coating