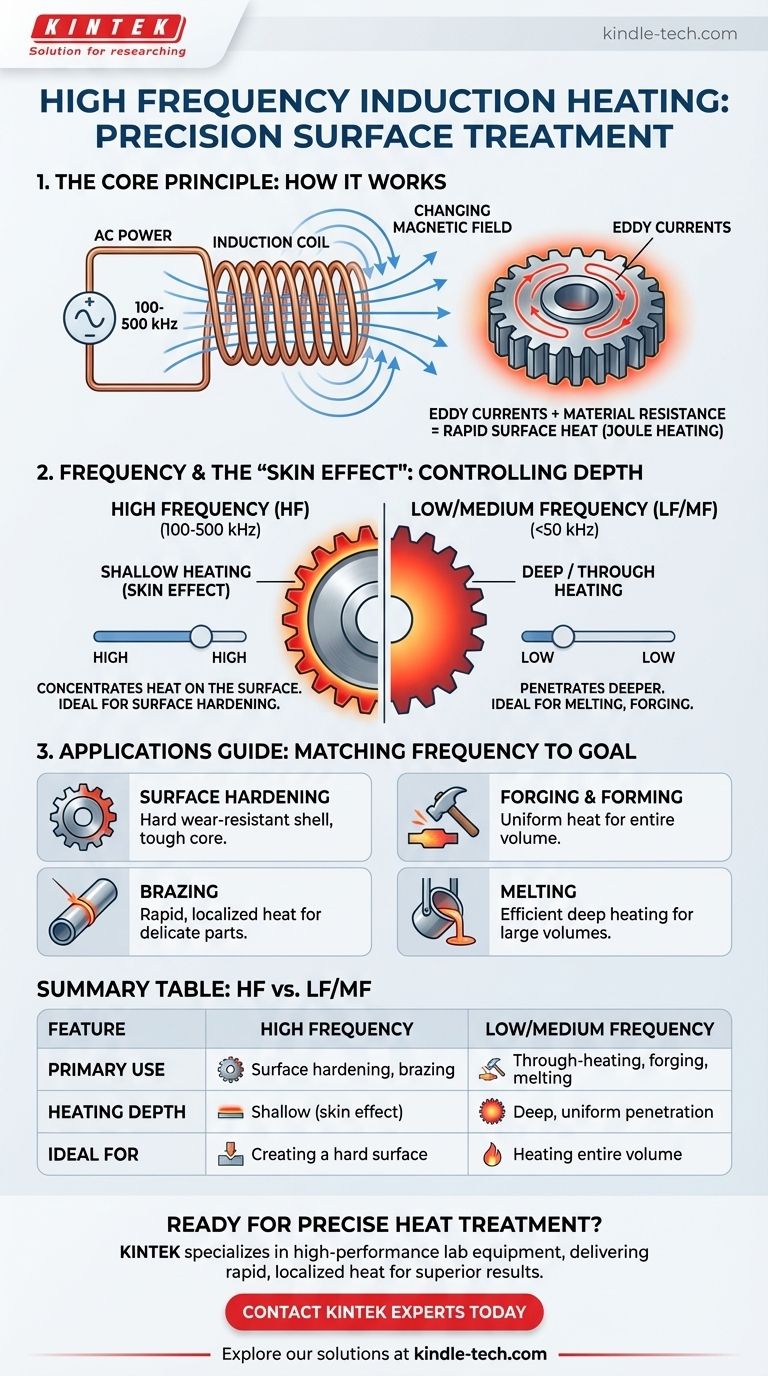

In essence, high frequency induction heating is a non-contact process that uses an alternating current, typically between 100 kHz and 500 kHz, to rapidly generate intense heat on the surface of a conductive material. The defining characteristic of using a high frequency is that it concentrates the heating effect in a very shallow layer, a phenomenon known as the "skin effect." This precision makes it ideal for applications where only the exterior of a part needs to be treated, such as surface hardening.

The central principle to grasp is that frequency is the primary control for heating depth. High frequency confines heat to the surface for treatments like case hardening, while lower frequencies penetrate deeper to heat the entire volume of a part for processes like melting or forging.

The Core Principle: How Induction Heating Works

Induction heating is a remarkably direct method of converting electrical energy into heat within a part itself, without flames or external heating elements. The process relies on fundamental principles of electromagnetism.

From Electricity to a Magnetic Field

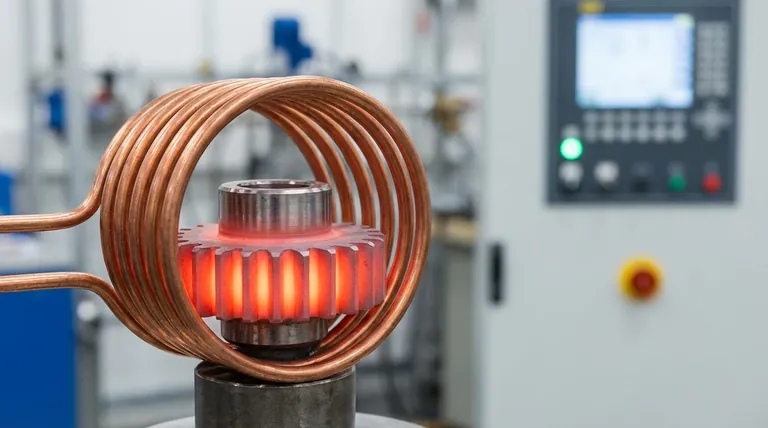

The process begins with an induction coil, often made of copper tubing, which acts as a solenoid. A powerful alternating current (AC) is passed through this coil, generating an intense and rapidly changing magnetic field in the space within and around it.

The Role of Eddy Currents

When a conductive workpiece, such as a steel gear, is placed inside this magnetic field, the field induces electrical currents within the metal. These are known as eddy currents, which mirror the path of the current in the main coil but flow in the opposite direction.

Generating Heat Through Resistance

The workpiece material has a natural electrical resistance. As these powerful eddy currents are forced to flow through the material, they overcome this resistance, and the energy is dissipated as heat. This is the same principle of resistive heating (Joule heating) that makes an electric stove burner glow.

Why Frequency is the Critical Control Parameter

The choice of AC frequency is not arbitrary; it is the single most important parameter for controlling where the heat is generated within the workpiece. This is due to a physical principle called the skin effect.

The "Skin Effect"

In AC circuits, current tends to flow more densely at the surface, or "skin," of a conductor. As the frequency of the current increases, this effect becomes more pronounced, forcing the eddy currents into an even thinner layer at the surface.

High Frequency for Surface Treatment

High frequency (HF) systems, operating from 100 kHz to 500 kHz, leverage the skin effect to its fullest. They concentrate immense energy into a surface layer that can be mere fractions of a millimeter thick.

This makes HF induction perfect for surface hardening (also known as case hardening), where the goal is to create a very hard, wear-resistant outer shell while leaving the core of the part tough and ductile to absorb shock.

Low and Medium Frequency for Deeper Heating

In contrast, lower frequencies (typically below 50 kHz) have a much less pronounced skin effect. The induced eddy currents can penetrate far deeper into the material, resulting in more uniform, through-part heating. This is essential for applications like melting large volumes of metal, forging, or through-hardening an entire component.

Understanding the Trade-offs

While powerful, high frequency induction is not a universal solution. The choice of frequency involves balancing several factors to optimize the process for a specific goal.

Precision vs. Application

High frequency provides unmatched precision for surface treatments. However, using an HF system to try and melt a large crucible of steel would be incredibly inefficient, as only the top layer would heat effectively. The equipment must be matched to the task.

Material Properties Matter

The electrical resistivity and magnetic properties of the workpiece interact with the frequency. A frequency that works perfectly for a carbon steel part may be less efficient for a low-resistivity material like copper or aluminum, requiring adjustments to the process parameters to achieve the desired heating profile.

The Importance of Coil Design

The efficiency of energy transfer depends heavily on the "coupling," or the proximity and shape of the coil relative to the workpiece. For precise surface heating with HF, coil design is even more critical to ensure the magnetic field is applied exactly where it is needed.

Making the Right Choice for Your Application

Selecting the correct frequency range is fundamental to a successful induction heating process. Your choice should be dictated entirely by the desired outcome for your material.

- If your primary focus is surface hardening or case hardening: High frequency is the definitive choice for creating a hard, shallow, wear-resistant layer on a component.

- If your primary focus is brazing small, delicate parts: High frequency provides the rapid, localized heat needed to melt the filler alloy without damaging the surrounding assembly.

- If your primary focus is heating an entire part for forging or forming: A low or medium frequency is required to ensure the heat penetrates uniformly throughout the component's volume.

- If your primary focus is melting a large volume of metal: A low frequency is essential to drive heat deep into the charge and create the stirring action needed for a homogenous melt.

Ultimately, mastering induction heating means understanding frequency as a precise tool to control exactly where and how your part is heated.

Summary Table:

| Feature | High Frequency (100-500 kHz) | Low/Medium Frequency (<50 kHz) |

|---|---|---|

| Primary Use | Surface hardening, case hardening, brazing | Through-heating, forging, melting |

| Heating Depth | Shallow (skin effect) | Deep, uniform penetration |

| Ideal For | Creating a hard, wear-resistant surface | Heating the entire volume of a part |

Ready to achieve precise, efficient heat treatment in your lab?

KINTEK specializes in high-performance lab equipment, including induction heating systems tailored for surface hardening, brazing, and more. Our solutions deliver rapid, localized heat for superior results and enhanced productivity.

Contact our experts today to discuss how KINTEK's induction heating technology can meet your specific laboratory needs.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What role does a vacuum hot pressing sintering furnace play in the fabrication of CuCrFeMnNi alloys? Achieve High Purity

- What are the advantages of using a vacuum hot press for CuCr50? Achieve Superior Density & Purity in Alloy Production

- Why is a high vacuum preferred over argon for sintering VC/Cu composites? Achieve Superior Wetting and Bond Strength

- What are the advantages of using vacuum hot pressing for CoCrCuFeNi? Superior Strength via Microstructural Control

- Why is the vacuum system of a Vacuum Hot Pressing furnace critical for ODS ferritic stainless steel performance?