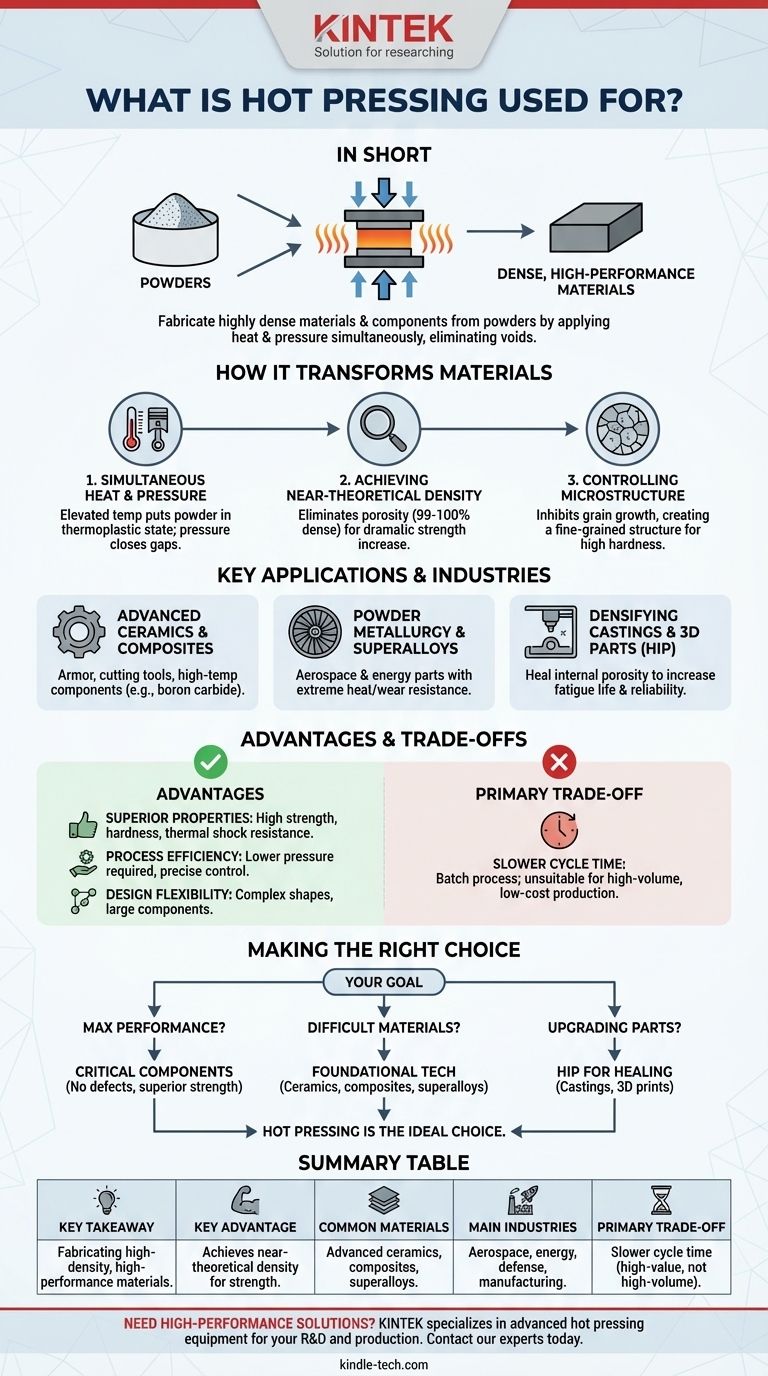

In short, hot pressing is used to fabricate highly dense, high-performance materials and components from powders. By applying heat and pressure simultaneously, the process consolidates powders into a solid mass, eliminating internal voids and creating parts with superior mechanical properties that are often impossible to achieve through other manufacturing methods.

The fundamental purpose of hot pressing is not just to shape a material, but to fundamentally engineer its internal microstructure. It is the chosen method when the primary goal is achieving maximum density and strength in materials that are otherwise difficult to consolidate.

How Hot Pressing Fundamentally Transforms Materials

Hot pressing is more than just a forming process; it is a materials science technique that actively improves the end product. The magic lies in the simultaneous application of thermal and mechanical energy.

Simultaneous Heat and Pressure

Unlike cold pressing, where pressure is applied first and then the part is heated (sintered), hot pressing does both at once. The elevated temperature puts the powder material into a thermoplastic state, making it more pliable and aiding mass transfer between particles.

This allows the applied pressure to be far more effective at closing the gaps and pores between powder grains.

Achieving Near-Theoretical Density

The primary outcome of this process is the elimination of porosity. By forcing the powder particles to deform and bond under heat, hot pressing can produce components that are 99-100% of their theoretical maximum density.

This void-free structure is directly responsible for the dramatic increase in a part's strength, durability, and resistance to failure.

Controlling Microstructure

The combination of heat and pressure also allows for precise control over the material's final grain structure. Because the process can be done at lower temperatures and for shorter times than conventional sintering, it effectively inhibits unwanted grain growth.

The result is a fine-grained microstructure, which is a key contributor to high material strength and hardness.

Key Applications and Industries

Because it produces superior materials, hot pressing is reserved for components where performance and reliability are non-negotiable.

Advanced Ceramics and Composites

Many advanced ceramics (like boron carbide or silicon nitride) and composite materials cannot be melted and cast like metals. Hot pressing is a primary method for consolidating these powders into dense, solid forms for use in armor, cutting tools, and high-temperature industrial components.

Powder Metallurgy and Superalloys

The aerospace and energy industries rely on superalloys to create parts for extreme environments, like turbine blades. Hot pressing and its variant, Hot Isostatic Pressing (HIP), are used to consolidate superalloy powders into fully dense components that have exceptional resistance to heat, wear, and fatigue.

Densifying Castings and 3D-Printed Parts

A critical application, often using HIP, is to heal defects in components made by other methods. Metal castings and even some metal 3D-printed parts can contain microscopic internal pores. Subjecting these parts to a hot pressing cycle collapses these voids, significantly increasing their fatigue life and reliability.

Understanding the Advantages and Trade-offs

Choosing hot pressing involves weighing its significant benefits against its process limitations. It is a specialized tool for specific challenges.

Advantage: Superior Material Properties

The ability to create fully dense, fine-grained parts is the number one reason to use hot pressing. This directly translates to higher strength, hardness, and resistance to wear and thermal shock.

Advantage: Process Efficiency and Control

By heating the material during compression, the pressure required can be as little as one-tenth of that needed for cold pressing. This can mean smaller, less expensive equipment. Modern IT controls also allow for precise management of the densification process, ensuring consistent quality.

Advantage: Design Flexibility

The process is well-suited for producing parts with complex shapes and accurate dimensions. It can also be used to fabricate very large-diameter components that would be difficult to produce otherwise.

The Primary Trade-off: Cycle Time and Volume

Hot pressing is a batch process. Heating, pressing, and cooling a single component or a small batch of components takes a significant amount of time. This makes it unsuitable for the high-volume, low-cost production typical of consumer goods. Its value is in high-performance applications, not mass production.

Making the Right Choice for Your Goal

Ultimately, the decision to use hot pressing depends entirely on your material and performance requirements.

- If your primary focus is maximum performance and reliability: Hot pressing is the ideal choice for creating critical components that are free of internal defects and possess superior strength.

- If your primary focus is processing difficult-to-form materials: For advanced ceramics, composites, or superalloys that cannot be melted and cast, hot pressing is a foundational manufacturing technology.

- If your primary focus is upgrading existing components: Use Hot Isostatic Pressing (HIP) to heal internal porosity in castings or 3D-printed metal parts, dramatically increasing their service life.

Choosing the right manufacturing process is about matching the technique to the engineering challenge you need to solve.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Primary Use | Fabricating high-density, high-performance materials from powders. |

| Key Advantage | Achieves near-theoretical density for superior strength and durability. |

| Common Materials | Advanced ceramics, composites, superalloys. |

| Main Industries | Aerospace, energy, defense, manufacturing. |

| Primary Trade-off | Slower cycle time, making it ideal for high-value, not high-volume, production. |

Need to fabricate high-performance components with superior strength and density?

At KINTEK, we specialize in providing advanced hot pressing solutions and lab equipment for developing and producing high-performance ceramics, composites, and superalloys. Our expertise can help you achieve the material properties critical for your most demanding applications.

Contact our experts today to discuss how our equipment can enhance your R&D and production capabilities.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What advantages does hot pressing sintering equipment provide for NASICON? Achieve 100% Dense Solid Electrolyte Plates

- What conditions does a Vacuum Hot Pressing Furnace provide for Copper-MoS2-Mo composites? Achieve Peak Densification

- What role does a high-temperature hot press play in the sintering of NITE-SiC? Optimize Your Densification Process

- How does the uniaxial pressing function of a vacuum hot press furnace influence the microstructure of ZrC-SiC ceramics?

- What are the advantages of using a vacuum hot press for CuCr50? Achieve Superior Density & Purity in Alloy Production