In essence, plasma arc melting (PAM) is a highly specialized process that uses a jet of ionized gas—a plasma—to melt and refine metals. Unlike conventional melting, which simply liquefies a material, PAM is an ultra-high-temperature furnace technology designed to produce exceptionally clean and high-quality ingots from reactive and high-performance metals like titanium and superalloys.

Plasma arc melting is not just a melting process; it is a purification process. Its primary value lies in its ability to remove contaminants and achieve precise metallurgical control, making it indispensable for critical applications in aerospace, medical, and defense industries.

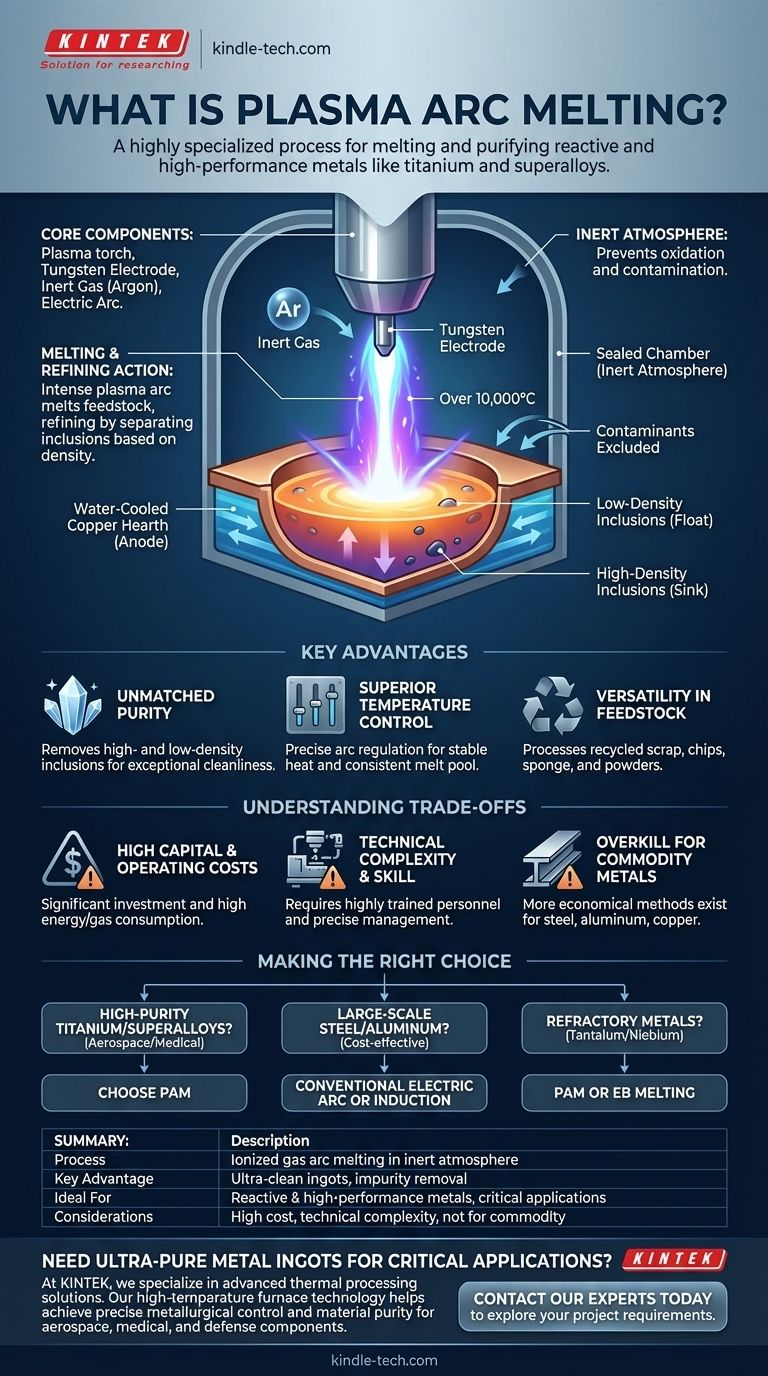

How Plasma Arc Melting Works

Understanding the PAM process requires looking at how it generates and uses a controlled plasma arc within an inert environment to achieve results that other methods cannot.

The Core Components

A plasma arc furnace consists of one or more plasma torches, which act as the heat source. A torch uses a tungsten electrode (cathode) through which an inert gas, typically argon, is passed. A powerful electric arc ionizes this gas, converting it into a superheated plasma jet.

The Melting and Refining Action

The material to be melted is placed in a water-cooled copper hearth or crucible, which acts as the anode. The plasma arc is directed at the material, with temperatures in the arc's core reaching over 10,000°C. This intense, focused energy rapidly melts the feedstock.

As the metal liquefies into a molten pool, the process begins its refining work. Lighter impurities, known as low-density inclusions, float to the surface and can be consolidated, while heavier high-density inclusions sink and become trapped at the bottom of the solidified ingot.

The Importance of the Inert Atmosphere

The entire process is conducted in a sealed chamber filled with an inert gas. This controlled atmosphere is critical because it prevents the highly reactive molten metal from being contaminated by oxygen and nitrogen from the air, which would degrade its properties.

Key Advantages of the PAM Process

Engineers and metallurgists choose PAM when the material's final quality is non-negotiable. Its advantages are centered on purity and control.

Unmatched Purity and Cleanliness

By effectively removing both high- and low-density inclusions, PAM produces a metal ingot with exceptional cleanliness. This is vital for materials like titanium alloys, where even microscopic impurities can lead to premature fatigue failure in a jet engine turbine blade or a medical implant.

Superior Temperature and Process Control

The energy output of the plasma torch can be precisely regulated, independent of the operating pressure inside the furnace. This provides a very stable and controllable heat source, allowing for a consistent melt pool and a predictable, uniform final product.

Versatility in Feedstock Material

PAM furnaces are flexible and can process a wide range of raw material forms. This includes everything from recycled scrap and machined chips to raw metal sponge and powders, allowing for efficient use of resources.

Understanding the Trade-offs and Limitations

While powerful, plasma arc melting is not a universal solution. Its specialized nature comes with significant considerations.

High Capital and Operating Costs

PAM furnaces are complex, precision-engineered systems that represent a significant capital investment. They also have high operating costs due to their consumption of electrical energy and large quantities of inert gas.

Technical Complexity and Skill Requirement

Operating a PAM furnace is not a simple task. It requires highly trained personnel who can manage the delicate balance between arc power, gas flow, cooling rates, and melting progression to ensure a successful outcome.

It's Overkill for Commodity Metals

For standard carbon steel, aluminum, or copper, much cheaper and higher-volume methods like induction furnaces or electric arc furnaces are far more economical. PAM is reserved for high-value materials where its refining benefits justify the cost.

Making the Right Choice for Your Goal

Selecting a melting technology depends entirely on your material and performance requirements. PAM is a tool for achieving the highest standards of metallurgical purity.

- If your primary focus is producing high-purity titanium or superalloys for aerospace or medical use: PAM is the industry standard, offering unparalleled cleanliness and property control.

- If your primary focus is large-scale, cost-effective production of steel or aluminum: Conventional electric arc or induction furnaces are the appropriate, economical choice.

- If your primary focus is melting refractory metals like tantalum or niobium: PAM is a leading candidate, competing with Electron Beam (EB) melting, which operates in a high vacuum.

Ultimately, understanding the capabilities of plasma arc melting empowers you to create materials that meet the most demanding specifications with uncompromising quality.

Summary Table:

| Feature | Description |

|---|---|

| Process | Uses an ionized gas (plasma) arc to melt and refine metals in an inert atmosphere. |

| Key Advantage | Produces ultra-clean ingots by removing both high- and low-density impurities. |

| Ideal For | Reactive & high-performance metals (titanium, superalloys), aerospace, medical implants. |

| Considerations | High capital/operating costs, technical complexity, not for commodity metals. |

Need to produce ultra-pure metal ingots for critical applications?

At KINTEK, we specialize in advanced thermal processing solutions for demanding laboratory and R&D environments. Our expertise in high-temperature furnace technology can help you achieve the precise metallurgical control and material purity required for aerospace, medical, and defense components.

Let's discuss how our specialized equipment can meet your specific material challenges. Contact our experts today to explore your project requirements.

Visual Guide

Related Products

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Lab-Scale Vacuum Induction Melting Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- What is the melting of electric furnace? A Guide to Precise, Efficient Metal Melting

- What are the disadvantages of coreless type induction furnace? Key Trade-offs in Flexibility vs. Efficiency

- Does induction heating work with copper? Yes, with the right high-frequency equipment.

- How does heating occur in induction heating? Unlock the Power of Internal, Non-Contact Heat

- What is the efficiency of an induction furnace? Achieve 75-95% Energy Savings with Direct Heating

- How hot does a magnetic induction heater get? Achieve Precise Temperatures from 100°C to 3000°C

- How to design induction furnace? A Guide to Core Components and Efficient Melting Systems

- What metals can be melted in an induction furnace? A Guide to Efficient Melting for Any Conductive Metal