In short, "PVD diamond" is most often a marketing term, not a technical one. It describes a product coated using Physical Vapor Deposition (PVD) to achieve a highly durable finish that may have a specific aesthetic, but it is not a layer of actual diamond. The PVD process bonds a microscopic-thin film of a hard, resilient material onto a base metal in a vacuum, creating a surface far superior to traditional plating.

The term "PVD diamond" is used to convey the toughness and premium quality of a coating, not its composition. The underlying technology, Physical Vapor Deposition, is a sophisticated vacuum coating process that creates exceptionally hard, pure, and durable thin-film surfaces on a wide range of products.

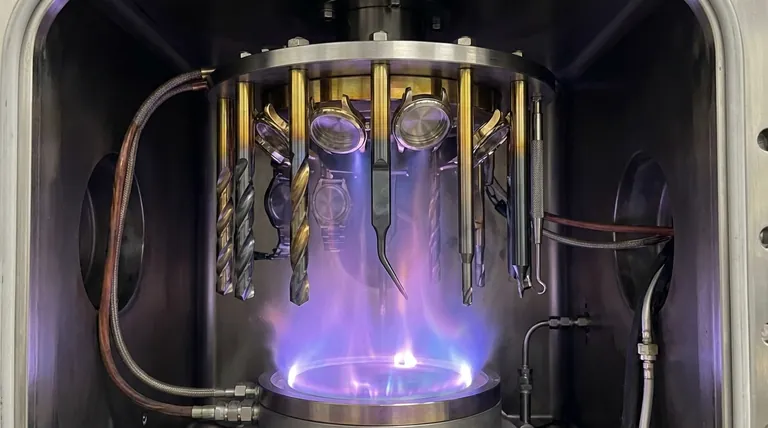

How Does the PVD Process Actually Work?

Physical Vapor Deposition is a high-tech process that fundamentally changes a material's surface properties. It's best understood as a three-stage sequence performed inside a high-vacuum chamber.

Stage 1: Vaporization

First, a solid source material, often a high-purity metal or ceramic like titanium or zirconium, is vaporized. This is done using intense heat or plasma, turning the solid material directly into a gas of individual atoms or molecules.

Stage 2: Migration

These vaporized particles then travel across the vacuum chamber. The vacuum is critical because it ensures there are no other atoms (like oxygen or nitrogen from the air) for the coating material to collide with, guaranteeing an extremely pure film.

Stage 3: Deposition

Finally, the vaporized material deposits onto the target object (the substrate). It builds up layer by layer, atom by atom, forming a thin, dense, and highly uniform coating that is molecularly bonded to the surface beneath it.

What PVD Coatings Actually Provide

The result of the PVD process is a finish that is far more than just a layer of paint. Its unique characteristics are why it's used in demanding fields from medical devices to aerospace.

Exceptional Hardness and Durability

PVD coatings are significantly harder and more resistant to corrosion and wear than coatings applied by traditional methods like electroplating. This bond at the atomic level makes the coating extremely difficult to chip or fade.

Superior Purity and Adhesion

Because it's applied in a vacuum, the coating is exceptionally pure and free of contaminants. The strong bond to the substrate means it won't flake or peel, providing long-lasting protection and color.

Environmentally Responsible

Compared to processes like electroplating, which involve harsh chemicals and produce hazardous waste, PVD is a clean, dry, and environmentally friendly process.

Understanding the Trade-offs

While PVD offers remarkable performance, it's crucial to understand its limitations. A clear understanding prevents misconceptions about what the coating can and cannot do.

It Is a Thin Film

The PVD coating is incredibly thin, often just a few microns thick. While extremely hard, it does not change the fundamental properties of the base material. The overall strength and dent resistance of an object depend on the substrate, not the coating.

Susceptible to Deep Gouges

The coating's hardness protects exceptionally well against light scratches and daily wear. However, a deep gouge or impact that deforms the base metal underneath can still damage or break through the PVD layer.

Quality Is Not Universal

The final quality, durability, and color of a PVD coating depend heavily on the specific materials used and the precision of the application process. A "PVD" label on its own is not a guarantee of the highest quality; the reputation of the manufacturer is also a key factor.

Making the Right Choice for Your Product

When evaluating a product marketed with a "PVD diamond" or similar finish, your decision should be guided by your primary goal for that item.

- If your primary focus is aesthetics and daily wear resistance: A PVD coating on jewelry or a watch is an excellent choice for maintaining color and preventing minor scratches.

- If your primary focus is extreme performance: For tools or industrial components, look for specific PVD coating types like TiN (Titanium Nitride) or DLC (Diamond-Like Carbon), as these offer documented hardness and lubricity properties.

- If your primary focus is value: Recognize that you are paying for a superior surface finish that drastically outperforms traditional plating, not for a product made of a new, indestructible material.

Ultimately, PVD is a proven technology that produces one of the most durable and high-quality surface finishes available today.

Summary Table:

| Feature | What PVD Coating Is | What PVD Coating Is Not |

|---|---|---|

| Composition | A thin film of metal or ceramic (e.g., Titanium Nitride) | A layer of actual diamond |

| Durability | Extremely hard, scratch-resistant, and corrosion-resistant | Indestructible or immune to deep gouges |

| Bonding | Molecular bond for superior adhesion, won't flake or peel | A superficial layer like paint or traditional plating |

| Process | A clean, dry, vacuum-based (Physical Vapor Deposition) process | A wet, chemical-heavy process like electroplating |

Need a durable, high-performance coating for your lab equipment or components?

At KINTEK, we specialize in advanced PVD coating solutions for laboratory needs. Our coatings provide exceptional hardness, purity, and longevity, protecting your valuable equipment from wear and corrosion. Whether you require specific coatings like TiN for tools or a durable finish for precision components, our expertise ensures a superior result.

Contact our coating experts today to discuss how KINTEK's PVD technology can enhance your products' performance and lifespan.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- CVD Diamond Domes for Industrial and Scientific Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- How do you calculate coating coverage? A Practical Guide to Accurate Material Estimation

- What is the hot filament chemical vapour deposition of diamond? A Guide to Synthetic Diamond Coating

- What is direct current DC magnetron sputtering? A Guide to High-Quality Thin Film Deposition

- What machine is used to make lab-grown diamonds? Discover the HPHT & CVD Technologies

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis