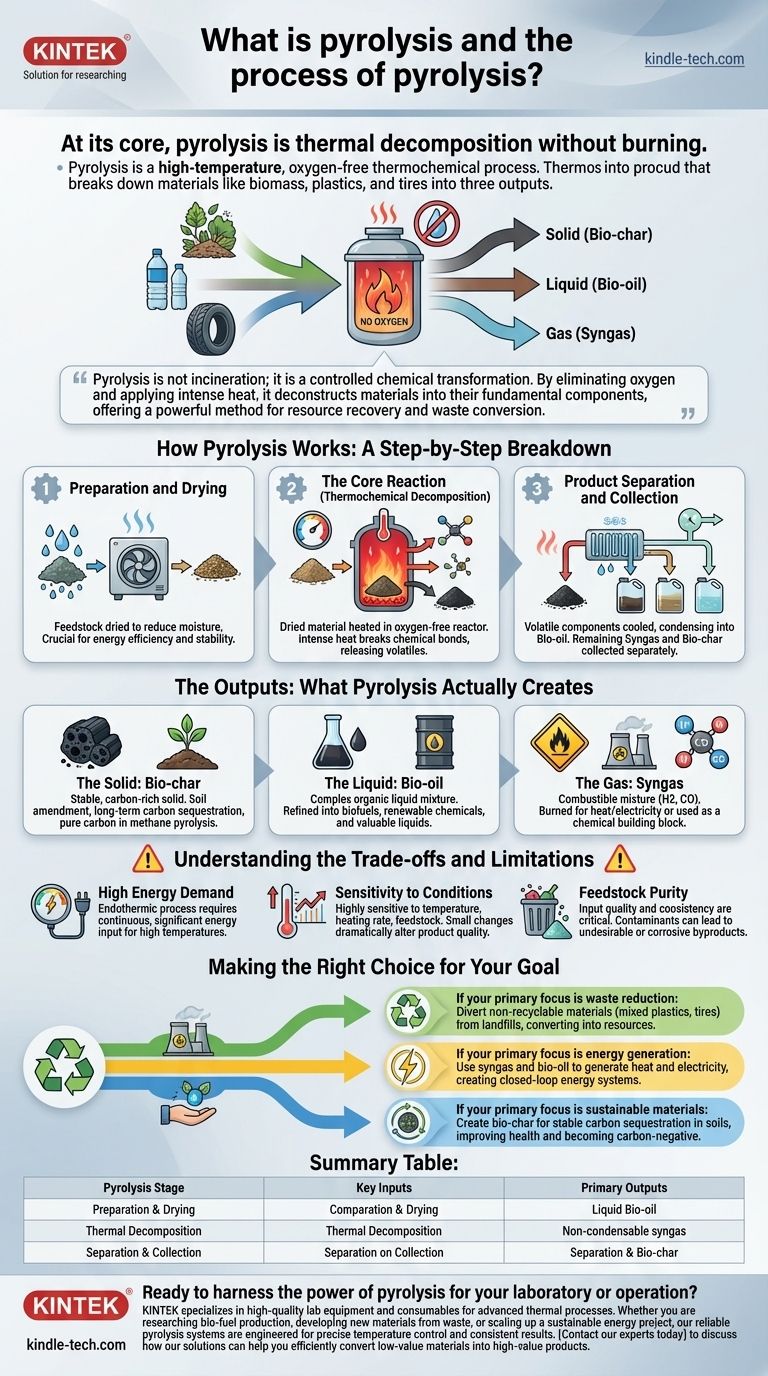

At its core, pyrolysis is thermal decomposition without burning. It is a thermochemical process that uses high temperatures in an oxygen-free environment to break down complex materials like biomass, plastics, or tires. Instead of combusting, the material deconstructs into three valuable outputs: a solid (bio-char), a liquid (bio-oil), and a gas (syngas).

Pyrolysis is not incineration; it is a controlled chemical transformation. By eliminating oxygen and applying intense heat, it deconstructs materials into their fundamental components, offering a powerful method for resource recovery and waste conversion.

How Pyrolysis Works: A Step-by-Step Breakdown

The pyrolysis process is a precise, multi-stage operation designed to control the breakdown of a feedstock into predictable outputs. Each stage serves a critical function in the overall transformation.

Stage 1: Preparation and Drying

Before the core reaction can begin, the input material, or feedstock, must be prepared. The most crucial step is drying the material to significantly reduce its moisture content.

Water requires a large amount of energy to vaporize and can interfere with the stability of the pyrolysis reaction. Effective drying ensures the process is more energy-efficient and consistent.

Stage 2: The Core Reaction (Thermochemical Decomposition)

The dried feedstock is fed into a sealed reactor devoid of oxygen. Here, it is subjected to very high temperatures, which act as the catalyst for its decomposition.

The intense heat breaks the complex chemical bonds within the material, causing it to break down and release volatile components. This is the central "pyrolysis" step where the material fundamentally changes its state.

Stage 3: Product Separation and Collection

As the volatile components leave the reactor as a hot gas, they are cooled. This causes certain compounds to condense into a liquid known as bio-oil.

The remaining non-condensable gases form syngas, which is collected separately. The solid, carbon-rich residue left behind in the reactor is bio-char.

The Outputs: What Pyrolysis Actually Creates

The value of pyrolysis lies in its ability to convert a single low-value input into multiple high-value outputs. The specific yield of each product depends on the feedstock and process conditions.

The Solid: Bio-char

Bio-char is a stable, carbon-rich solid similar to charcoal. It has excellent applications in agriculture as a soil amendment and is a recognized method for long-term carbon sequestration. In methane pyrolysis, this product is pure solid carbon.

The Liquid: Bio-oil

Also known as pyrolysis oil, this is a complex liquid mixture of organic compounds. After refining, it can be upgraded into biofuels, renewable chemicals, and other valuable liquid products.

The Gas: Syngas

Syngas, or synthesis gas, is a mixture of combustible gases, primarily hydrogen and carbon monoxide. It can be burned directly to generate heat and electricity to power the pyrolysis facility itself or be used as a chemical building block.

Understanding the Trade-offs and Limitations

While powerful, pyrolysis is a technically demanding process with specific operational challenges that must be managed for it to be effective and economical.

High Energy Demand

Pyrolysis is an endothermic process, meaning it requires a continuous and significant input of energy to maintain the high temperatures needed for the reaction. This energy cost is a primary factor in its economic viability.

Sensitivity to Conditions

The process is highly sensitive to key parameters like temperature, heating rate, and the type of feedstock used. Small variations can dramatically alter the ratio and quality of the final products, requiring sophisticated process controls.

Feedstock Purity

The quality and consistency of the input material are critical. Contaminants within the feedstock can lead to undesirable or corrosive byproducts, potentially damaging equipment and reducing the value of the outputs.

Making the Right Choice for Your Goal

Pyrolysis is not a single solution but a versatile platform technology. Its application depends entirely on the desired outcome, whether it's waste management, energy production, or material creation.

- If your primary focus is waste reduction: Pyrolysis offers a powerful way to divert non-recyclable materials like mixed plastics or tires from landfills, converting them into valuable resources.

- If your primary focus is energy generation: The syngas and bio-oil produced can be used to generate heat and electricity, creating a closed-loop energy system from various waste streams.

- If your primary focus is sustainable materials: The bio-char created is a stable form of carbon that can sequester carbon in agricultural soils, improving their health and creating a carbon-negative product.

Ultimately, pyrolysis provides a sophisticated toolkit for transforming low-value materials into high-value products through controlled thermal chemistry.

Summary Table:

| Pyrolysis Stage | Key Inputs | Primary Outputs |

|---|---|---|

| Preparation & Drying | Feedstock (e.g., biomass, plastics) | Dried material ready for decomposition |

| Thermal Decomposition | Heat (no oxygen) | Hot vapor of volatile compounds |

| Separation & Collection | Cooled vapor | Bio-oil (liquid), Syngas, Bio-char (solid) |

Ready to harness the power of pyrolysis for your laboratory or operation?

KINTEK specializes in high-quality lab equipment and consumables for advanced thermal processes. Whether you are researching bio-fuel production, developing new materials from waste, or scaling up a sustainable energy project, our reliable pyrolysis systems are engineered for precise temperature control and consistent results.

Contact our experts today to discuss how our solutions can help you efficiently convert low-value materials into high-value products.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Test Sieves and Sieving Machines

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Vacuum Dental Porcelain Sintering Furnace

People Also Ask

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products