In materials science and manufacturing, sputtering is a physical vapor deposition (PVD) method used to create exceptionally thin and uniform films of material. The process works by ejecting atoms from a source material, known as a "target," by bombarding it with high-energy ions inside a vacuum chamber. These ejected atoms then travel and deposit onto a substrate, gradually building a new material layer with highly controlled properties.

Sputtering is fundamentally a process of momentum exchange. It uses an energized gas plasma to create a stream of ions that act like a microscopic sandblaster, precisely chipping atoms off a target material and redepositing them to form a high-performance coating.

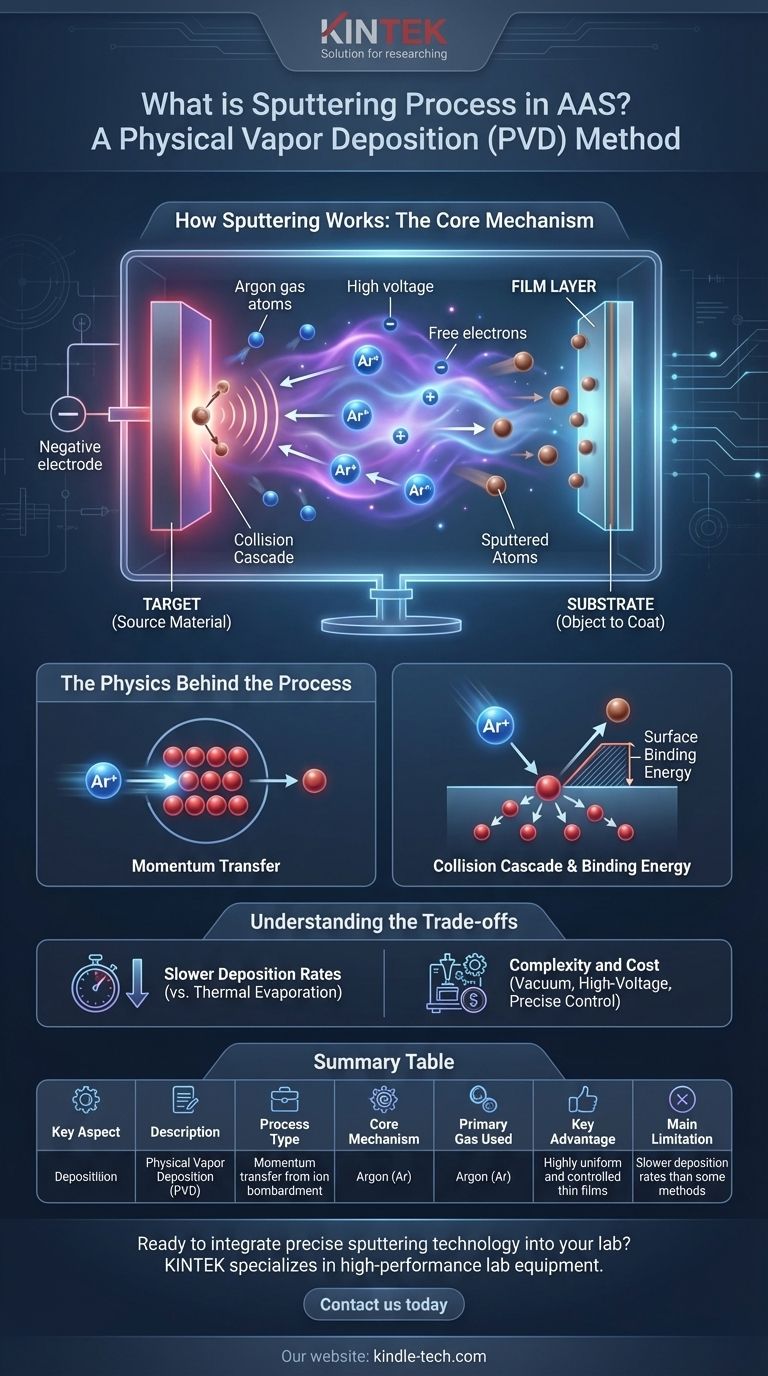

How Sputtering Works: The Core Mechanism

To understand sputtering, it's best to visualize it as a sequence of events occurring within a highly controlled environment.

The Essential Setup

The process begins by placing two key components into a vacuum chamber: the target and the substrate. The target is made of the material you wish to deposit, while the substrate is the object you want to coat.

The chamber is pumped down to a vacuum to remove contaminants. Then, a small, precise amount of an inert gas, almost always Argon (Ar), is introduced.

Creating the Plasma

A high voltage is applied across the chamber, making the target the negative electrode (cathode). This strong electric field energizes the inert gas.

Free electrons in the chamber accelerate and collide with the neutral Argon atoms, knocking off their electrons. This creates positively charged Argon ions (Ar+) and releases more electrons, resulting in a self-sustaining, glowing discharge known as a plasma.

The Bombardment Phase

The positively charged Argon ions are powerfully attracted and accelerated towards the negatively charged target.

They strike the target surface with tremendous kinetic energy. This is not a chemical reaction but a purely physical, high-impact collision.

Ejection and Deposition

The impact of the Argon ions dislodges or "sputters" atoms from the target material, ejecting them into the vacuum chamber.

These ejected atoms travel through the chamber and land on the substrate, condensing to form a thin, solid film. This process is repeated billions of time to build the film layer by atomic layer.

The Physics Behind the Process

Sputtering relies on fundamental principles of physics to achieve its precision. Understanding these concepts reveals why it is such a powerful technique.

It's All About Momentum Transfer

The core of the process is the transfer of momentum from the incoming Argon ion to the atoms of the target. It's a physical collision, similar to a cue ball striking a rack of billiard balls.

The efficiency of this transfer depends on the energy of the ions and the relative masses of the ion and target atoms.

Understanding the Collision Cascade

A single ion impact doesn't just chip off one atom. It sets off a collision cascade within the first few atomic layers of the target material.

Energy is transferred from atom to atom below the surface until the cascade reaches the surface with enough energy to eject an atom.

The Role of Surface Binding Energy

For a target atom to be sputtered, the energy it receives from the collision cascade must be greater than the surface binding energy. This is the energy that holds the atom to the bulk material.

This principle is why sputtering is a controlled physical process rather than a simple melting or evaporation technique.

Understanding the Trade-offs

While powerful, sputtering is not the ideal solution for every application. Its primary limitations are practical and economic.

Slower Deposition Rates

Compared to some other methods like thermal evaporation, sputtering can be a slower process. Building up thicker films can take a significant amount of time.

Complexity and Cost

Sputtering systems require a vacuum, high-voltage power supplies, and precise gas control. This makes the equipment complex and more expensive than simpler coating methods, representing a significant capital investment.

Applying This to Your Goal

Understanding sputtering allows you to appreciate its role in creating the high-performance materials that drive modern technology.

- If your primary focus is materials science: Recognize sputtering as a tool for creating films with precisely controlled grain structure, density, and orientation.

- If your primary focus is engineering or manufacturing: View sputtering as a highly reliable and repeatable process for producing uniform, durable, and functional coatings on components like semiconductors, optical lenses, and medical implants.

- If you are new to the topic: Remember the core concept: using high-energy ions in a plasma to physically knock atoms off a source and onto a surface.

Sputtering is a cornerstone technology, enabling the creation of materials and devices that would otherwise be impossible to fabricate.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process Type | Physical Vapor Deposition (PVD) |

| Core Mechanism | Momentum transfer from ion bombardment |

| Primary Gas Used | Argon (Ar) |

| Key Advantage | Highly uniform and controlled thin films |

| Main Limitation | Slower deposition rates than some methods |

Ready to integrate precise sputtering technology into your lab? KINTEK specializes in high-performance lab equipment, including sputtering systems, to help you achieve superior thin-film coatings for your research and production needs. Our experts are ready to help you select the perfect solution. Contact us today to discuss your specific application!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Gold Disc Electrode

People Also Ask

- How does plasma vapor deposition work? A Low-Temperature Coating Solution for Sensitive Materials

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What is plasma enhanced? A Guide to Low-Temperature, High-Precision Manufacturing

- What are the advantages of plasma enhanced CVD? Enable Low-Temperature, High-Quality Thin Film Deposition