The fundamental advantage of a sealed vacuum furnace is its ability to create a chemically pure environment, preventing unwanted reactions and contamination during high-temperature processing. This controlled atmosphere ensures superior material properties, process repeatability, and a level of quality that is often unachievable with conventional furnaces that operate in the presence of air.

A vacuum furnace isn't just about heating; it's about mastering the entire material science environment. By removing atmospheric gases, you gain precise control over the final chemical and physical properties of a component, making this technology indispensable for advanced materials and mission-critical parts.

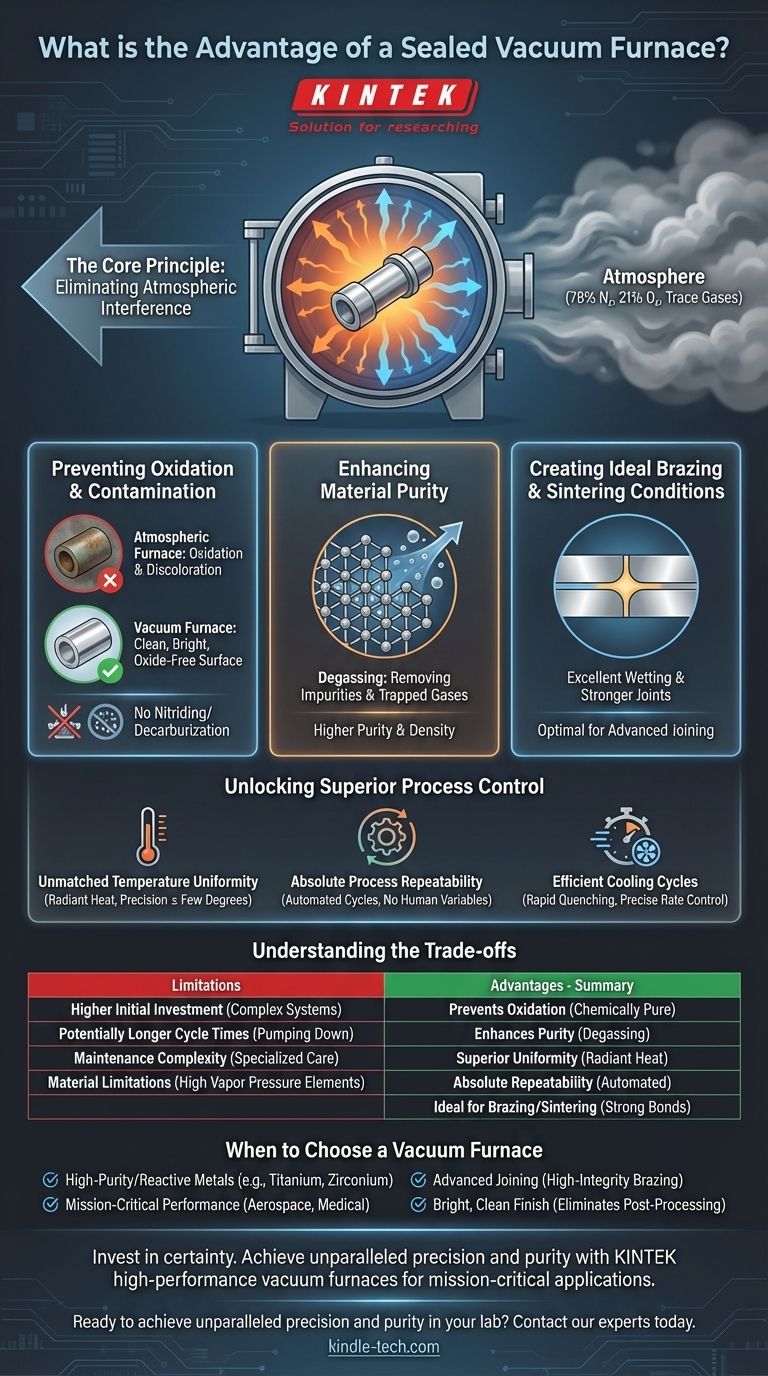

The Core Principle: Eliminating Atmospheric Interference

The primary value of a vacuum furnace stems from what it removes: the atmosphere. Normal air contains approximately 78% nitrogen, 21% oxygen, and trace amounts of other gases that can be highly reactive at elevated temperatures.

Preventing Oxidation and Contamination

At high temperatures, oxygen readily reacts with most metals to form a brittle, discolored oxide layer. A vacuum furnace removes virtually all the oxygen, completely preventing oxidation and resulting in clean, bright parts that often require no secondary cleaning.

Similarly, other atmospheric gases like nitrogen and water vapor can cause unwanted reactions like nitriding or decarburization, which negatively alter the material's surface properties.

Enhancing Material Purity

The vacuum does more than just prevent contamination from entering; it actively helps remove impurities from the material itself.

Volatile substances and trapped gases within the material can be "pulled out" by the vacuum system. This outgassing process, known as degassing, results in a final product with higher purity and density.

Creating Ideal Brazing and Sintering Conditions

Processes like brazing (joining metals with a filler alloy) and sintering (fusing powders into a solid mass) demand exceptionally clean surfaces.

The vacuum environment removes surface oxides just before the materials reach their melting or bonding temperatures, promoting excellent wetting and creating stronger, more reliable joints and denser final parts.

Unlocking Superior Process Control

By operating in a sealed environment, vacuum furnaces offer a level of control that atmospheric furnaces cannot match. This control translates directly to quality and consistency.

Unmatched Temperature Uniformity

In a conventional furnace, heat is transferred via convection (air currents), which can create hot and cold spots. In a vacuum, heat is transferred primarily through radiation, which is far more uniform.

This ensures the entire workpiece, regardless of its geometry, reaches and maintains the target temperature with extreme precision, typically within a few degrees.

Absolute Process Repeatability

Modern vacuum furnaces are highly automated. The entire heat treatment cycle—from pumping down the vacuum to precise heating ramps, soak times, and controlled cooling—is managed by a computer.

This removes human variables and guarantees that every part in a batch, and every subsequent batch, undergoes the exact same metallurgical process, ensuring consistent, repeatable results.

Efficient Cooling Cycles

Many vacuum furnaces are equipped with systems for rapid cooling, or quenching, using high-pressure inert gas like argon or nitrogen.

This allows for precise control over the cooling rate, which is critical for achieving specific hardness and microstructures in steels and other alloys. It also significantly shortens the overall process cycle time.

Understanding the Trade-offs

While powerful, vacuum furnaces are not the universal solution for all heat treatment needs. Objectivity requires acknowledging their limitations.

Higher Initial Investment

Vacuum furnaces are complex systems involving vacuum pumps, sealed chambers, and sophisticated control systems. This makes their initial capital cost significantly higher than that of conventional atmospheric furnaces.

Potentially Longer Cycle Times

While quenching can be rapid, the initial step of "pumping down" the chamber to the required vacuum level takes time. For some simple, low-value processes, the total cycle time may be longer than in an atmospheric furnace.

Maintenance Complexity

The vacuum system, including pumps, valves, and chamber seals, requires specialized and diligent maintenance to ensure optimal performance and prevent leaks, which can compromise the entire process.

Material Limitations

Materials with a high vapor pressure can be problematic. In a high vacuum, elements like zinc, cadmium, magnesium, or lead can "boil off" or sublimate from the alloy, altering its composition.

When to Choose a Vacuum Furnace

Your decision should be driven by the required outcome for your component. A vacuum furnace is the correct choice when precision and purity are non-negotiable.

- If your primary focus is high-purity or reactive metals: Choose a vacuum furnace for materials like titanium, zirconium, and certain superalloys that are intolerant of atmospheric contamination.

- If your primary focus is mission-critical performance: Use a vacuum furnace for aerospace, medical, or defense components where metallurgical perfection and repeatable mechanical properties are paramount.

- If your primary focus is advanced joining: A vacuum furnace is essential for high-integrity brazing and diffusion bonding, where surface cleanliness dictates the strength of the final bond.

- If your primary focus is a bright, clean finish: Select a vacuum furnace to eliminate post-processing steps like acid cleaning or sandblasting, saving time and resources.

Ultimately, a vacuum furnace is an investment in certainty, delivering unparalleled control over the final outcome of your material.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Prevents Oxidation & Contamination | Creates a chemically pure environment, eliminating surface reactions. |

| Enhances Material Purity | Removes impurities and gases from the material itself (degassing). |

| Superior Temperature Uniformity | Radiant heating ensures even heat distribution for consistent results. |

| Absolute Process Repeatability | Automated cycles guarantee identical treatment for every batch. |

| Ideal for Brazing & Sintering | Promotes perfect wetting and strong bonds on exceptionally clean surfaces. |

Ready to achieve unparalleled precision and purity in your lab?

KINTEK specializes in high-performance vacuum furnaces designed for mission-critical applications in aerospace, medical, and advanced materials R&D. Our equipment delivers the controlled environment you need to prevent contamination, ensure repeatable results, and unlock superior material properties.

Invest in certainty for your most critical processes. Contact our experts today to discuss how a KINTEK vacuum furnace can meet your specific laboratory needs.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Can I vacuum the inside of my furnace? A Guide to Safe DIY Cleaning vs. Professional Service

- At what temperature does molybdenum evaporate? Understanding Its High-Temperature Limits

- Why would you braze instead of solder? For Superior Joint Strength and High-Temperature Performance

- What is the maximum temperature in a vacuum furnace? It Depends on Your Materials and Process Needs

- Can an arc happen in a vacuum? Yes, and here's how to prevent it in your high-voltage design.