At its core, the annealing process systematically alters a material's properties by making it softer and more ductile. This is achieved through a controlled heat treatment cycle that involves heating the material to a specific temperature, holding it there, and then cooling it slowly. The primary goals are to relieve internal stresses, increase softness and ductility, and refine the material's internal grain structure, making it easier to work with.

The central purpose of annealing is to fundamentally "reset" a material's microstructure. By reducing internal defects and relieving stress, it trades hardness and strength for a significant increase in ductility and workability.

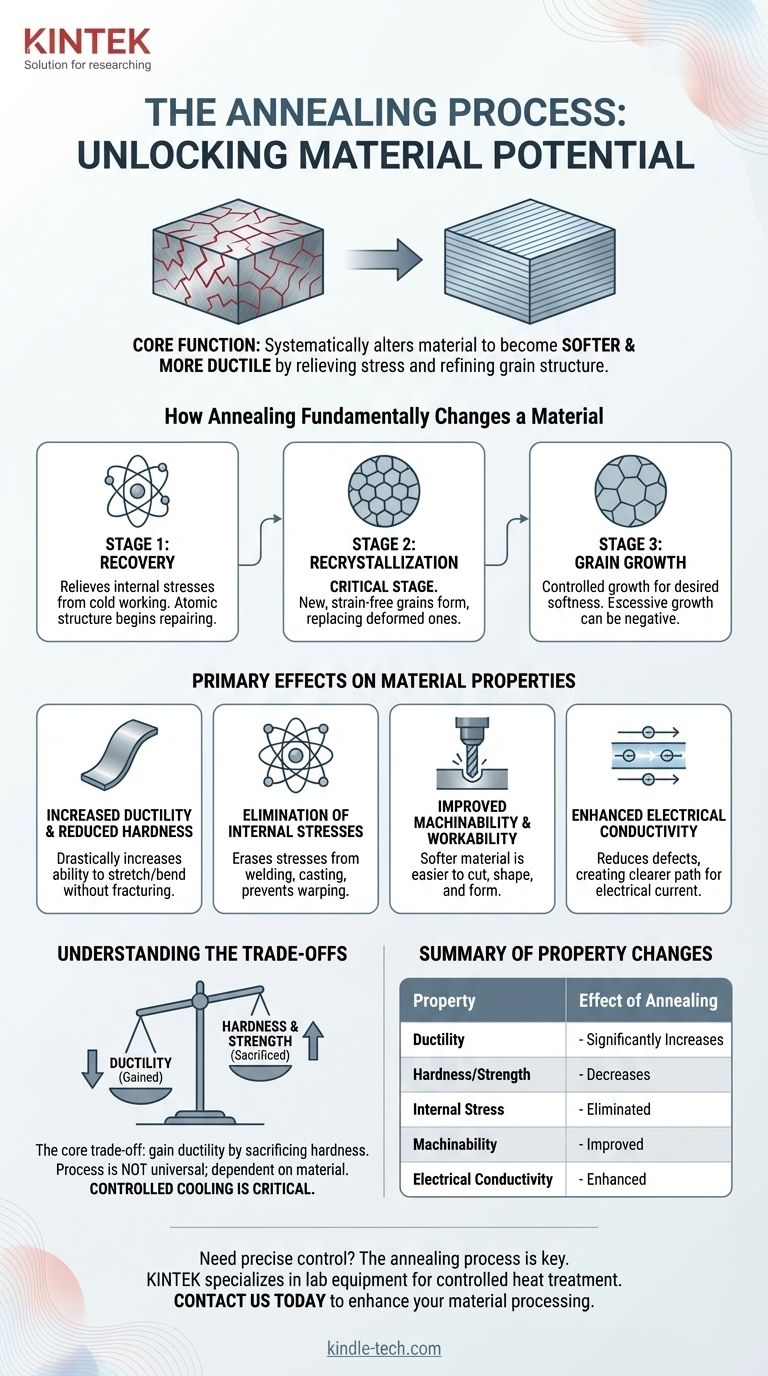

How Annealing Fundamentally Changes a Material

Annealing is not merely a heating process; it's a precise, three-stage transformation at the microscopic level. Understanding these stages is key to understanding its effects on a material's final properties.

Stage 1: Recovery

Before any major structural changes, the material first undergoes recovery. As the temperature rises, this initial stage relieves internal stresses that may have been introduced during processes like cold working or machining. The atomic structure gains enough energy to begin repairing minor defects.

Stage 2: Recrystallization

This is the most critical stage. As the material is held at its target temperature, new, strain-free grains begin to form and grow. These new crystals replace the old, deformed ones that were full of dislocations—microscopic defects that make a material hard and brittle.

Stage 3: Grain Growth

If the material is held at the annealing temperature for too long, the new, strain-free grains will continue to grow larger. This stage must be carefully controlled, as excessive grain growth can sometimes negatively impact certain properties, but a controlled growth phase is essential for achieving the desired softness.

The Primary Effects on Material Properties

The microstructural reset that occurs during annealing translates directly into tangible changes in the material's mechanical and physical behavior.

Increased Ductility and Reduced Hardness

This is the most well-known effect. By eliminating dislocations and creating a more uniform grain structure, annealing drastically increases a material's ability to be stretched, bent, or formed without fracturing. This comes at the direct expense of hardness and tensile strength.

Elimination of Internal Stresses

Processes like welding, casting, and cold forming create significant stress within a material's structure. Annealing allows the atomic lattice to relax into a lower-energy state, effectively erasing this internal stress. This is critical for preventing warping, cracking, or dimensional instability later in the part's life.

Improved Machinability and Workability

A softer, more ductile, and stress-free material is fundamentally easier to cut, shape, and form. The improved workability after annealing reduces tool wear and allows for more aggressive manufacturing processes, such as deep drawing or complex bending.

Enhanced Electrical Conductivity

The crystal structure dislocations that make a material hard also impede the flow of electrons. By reducing the number of these defects, the annealing process creates a clearer path for electrical current, often resulting in a measurable increase in conductivity.

Understanding the Trade-offs

Annealing is a powerful tool, but its application involves balancing competing properties. It is not a universal solution for improving a material.

The Hardness vs. Ductility Balance

The core trade-off is unavoidable: you gain ductility by sacrificing hardness and strength. The goal of annealing is to move the material to a softer, more workable state. If high strength is the end goal, another form of heat treatment will be required after the forming process is complete.

The Process is Not Universal

The correct annealing process is highly dependent on the specific material. The required temperatures, hold times, and cooling rates for steel are vastly different from those for aluminum, copper, or brass. Each alloy system has its own unique requirements to achieve the desired microstructural changes.

Controlled Cooling is Critical

The rate of cooling is arguably as important as the heating temperature. The characteristically slow cooling rate of annealing is what allows the new, stress-free grain structure to form properly. Cooling too quickly can introduce new stresses or create a different, harder microstructure, defeating the purpose of the process.

Making the Right Choice for Your Goal

Annealing should be viewed as a precise tool to prepare a material for a specific task or to restore its properties after a demanding process.

- If your primary focus is preparing for significant shaping (e.g., deep drawing or stamping): Annealing is essential to maximize ductility and prevent the material from cracking during forming.

- If your primary focus is stabilizing a part after welding or heavy machining: A stress-relief anneal is critical to prevent future distortion and ensure dimensional accuracy.

- If your primary focus is restoring workability to a strain-hardened material: Annealing can reset the microstructure, making the material soft and ductile again for further processing steps.

Ultimately, annealing provides you with precise control over a material's internal structure to achieve specific, predictable engineering outcomes.

Summary Table:

| Property Change | Effect of Annealing |

|---|---|

| Ductility | Significantly Increases |

| Hardness/Strength | Decreases |

| Internal Stress | Eliminated |

| Machinability | Improved |

| Electrical Conductivity | Enhanced |

Need precise control over your material's properties? The annealing process is key to achieving softer, more workable metals for manufacturing and R&D. KINTEK specializes in the lab equipment and consumables required for controlled heat treatment, serving the precise needs of laboratories and material scientists. Contact us today to discuss how our solutions can enhance your material processing and achieve your specific engineering outcomes.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

People Also Ask

- What temperature is tube annealing? A Guide to Material-Specific Ranges for Optimal Results

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- How do you clean a quartz tube furnace? Prevent Contamination & Extend Tube Lifespan

- What is quartz tube heating? Achieve Instant, Targeted Heat with Infrared Radiation

- How do you clean a tubular furnace tube? A Step-by-Step Guide to Safe and Effective Maintenance