At its core, a pressing machine is a tool designed to apply controlled force to a workpiece. Its applications are incredibly diverse, ranging from shaping massive automotive body panels and forging industrial parts to assembling delicate electronics and compacting pharmaceutical powders. These machines are the workhorses of modern manufacturing, used to cut, bend, form, join, and mold materials with precision.

The true function of a pressing machine isn't just to squash things; it's to use precisely controlled pressure to fundamentally transform a material's shape, structure, or composition. This makes it an indispensable tool in nearly every manufacturing sector.

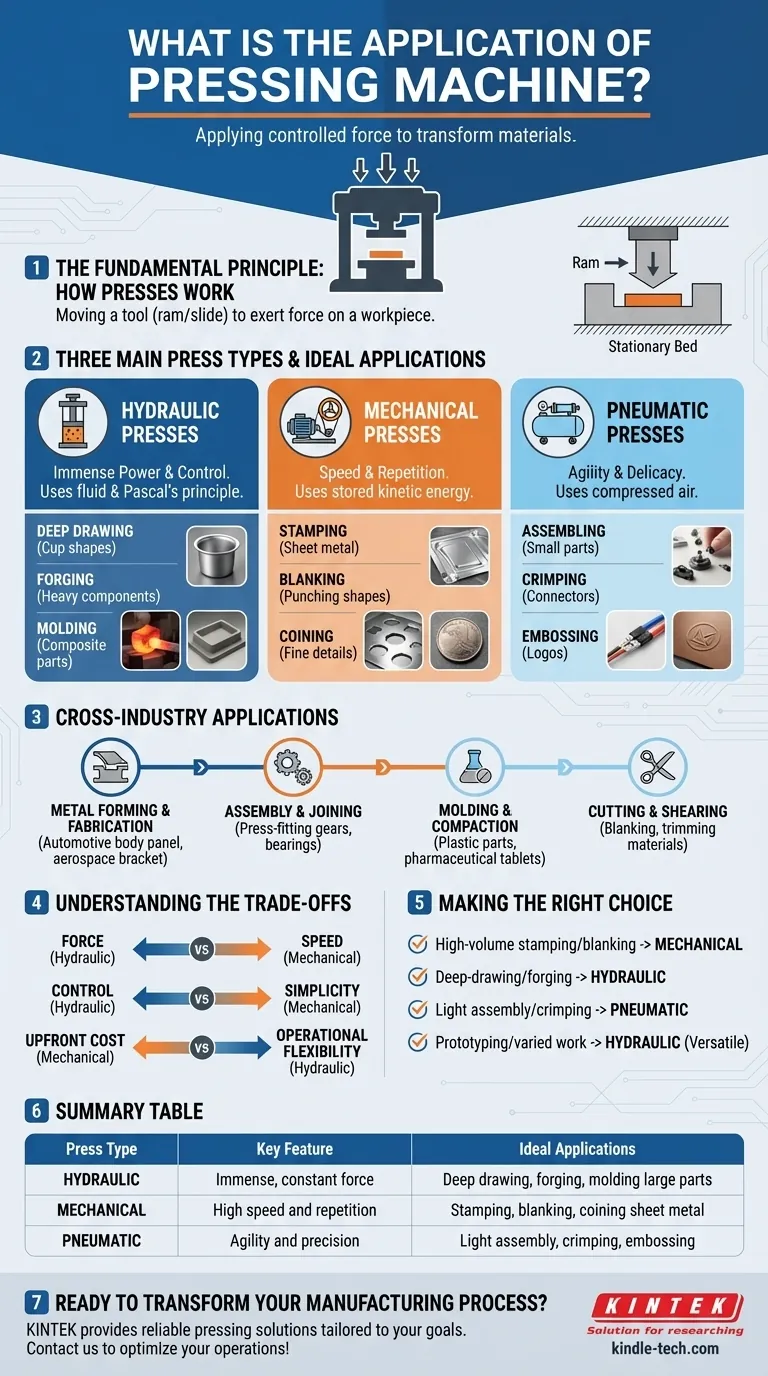

The Fundamental Principle: How Presses Work

A pressing machine operates by moving a tool, known as a ram or slide, to exert force on a workpiece, which is typically secured on a stationary bed or anvil. The method used to generate this force defines the type of press and its ideal applications.

Hydraulic Presses: Immense Power and Control

Hydraulic presses use a fluid-filled cylinder and piston system, operating on Pascal's principle. This design allows them to generate enormous, constant force throughout the entire stroke of the ram.

This makes them ideal for operations requiring significant, sustained pressure, such as deep drawing (forming deep cup-like shapes), forging heavy-duty components, and molding large composite parts.

Mechanical Presses: Speed and Repetition

Mechanical presses use a motor connected to a flywheel, which stores kinetic energy. A clutch and crank system converts this rotational energy into the linear, reciprocating motion of the ram.

Their strength lies in speed and consistency, making them the standard for high-volume operations like stamping, blanking (punching out shapes from sheet metal), and coining (forming fine details on a surface).

Pneumatic Presses: Agility and Delicacy

Pneumatic presses, often called air presses, use compressed air to drive the ram. They are much faster than hydraulic presses but generate significantly less force.

This makes them perfect for light-duty tasks that require speed and precision, such as assembling small components, press-fitting bearings, embossing logos, and crimping electrical connectors.

A Cross-Industry Look at Key Applications

While the mechanisms differ, the end goal is to manipulate a material. The applications of pressing machines are best understood by the operations they perform across various industries.

Metal Forming and Fabrication

This is the most common application domain. In the automotive, aerospace, and appliance industries, presses are used for stamping body panels, bending structural brackets, and punching holes in sheet metal with extreme accuracy.

Assembly and Joining

Presses are critical for joining parts without welding or fasteners. Press-fitting a shaft into a bearing or a gear onto a motor shaft is a common assembly operation that relies on the precise application of force.

Molding and Compaction

In plastics and composites manufacturing, compression molding uses a press to apply heat and pressure to raw material in a mold cavity. Similarly, the pharmaceutical industry uses specialized presses to compact powders into precisely dosed tablets.

Cutting and Shearing

Before a part can be formed, the raw material often needs to be cut to size. Presses equipped with cutting dies perform blanking and trimming operations, producing perfectly shaped blanks for subsequent manufacturing steps at high speed.

Understanding the Trade-offs

Choosing the right press technology is a critical engineering decision that balances performance, cost, and the specific requirements of the material and process.

Force vs. Speed

The primary trade-off is between force and cycle speed. Hydraulic presses deliver unmatched, consistent force but are generally slower. Mechanical presses are much faster but their force varies throughout the stroke, peaking at the bottom.

Control vs. Simplicity

Hydraulic systems offer superior control over pressure, speed, and stroke length, which is vital for complex forming operations. Mechanical presses are simpler in principle but can be more complex and costly to maintain due to their numerous moving parts.

Upfront Cost vs. Operational Flexibility

Mechanical presses are often preferred for dedicated, high-volume production lines due to their speed. Hydraulic presses, with their adjustable force and stroke, offer greater flexibility, making them a better choice for custom fabrication shops or processes with varying requirements.

Making the Right Choice for Your Goal

The best machine is the one that aligns with your specific manufacturing objective.

- If your primary focus is high-volume stamping or blanking of sheet metal: A mechanical press is the industry standard for its unmatched speed and repeatability.

- If your primary focus is deep-drawing complex shapes or forging metal: The constant, controllable power of a hydraulic press is essential for success.

- If your primary focus is light assembly, crimping, or delicate marking: A pneumatic press provides the necessary speed and control without risking damage from excessive force.

- If your primary focus is prototyping or low-volume, varied work: The flexibility and precise control of a hydraulic press make it the most versatile and cost-effective solution.

Ultimately, selecting the right pressing technology is about understanding the precise relationship between force, speed, and the material you intend to transform.

Summary Table:

| Press Type | Key Feature | Ideal Applications |

|---|---|---|

| Hydraulic | Immense, constant force | Deep drawing, forging, molding large parts |

| Mechanical | High speed and repetition | Stamping, blanking, coining sheet metal |

| Pneumatic | Agility and precision | Light assembly, crimping, embossing |

Ready to Transform Your Manufacturing Process?

Choosing the right pressing machine is critical for your production efficiency and product quality. Whether you're in high-volume metal stamping, complex deep-drawing, or delicate assembly work, KINTEK has the expertise and equipment to meet your specific needs.

As a specialist in lab and industrial equipment, KINTEK provides reliable pressing solutions tailored to your manufacturing goals. Our team can help you select the ideal hydraulic, mechanical, or pneumatic press to optimize your operations.

Contact KINTEK today to discuss your application and discover how our pressing machines can enhance your manufacturing capabilities!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples