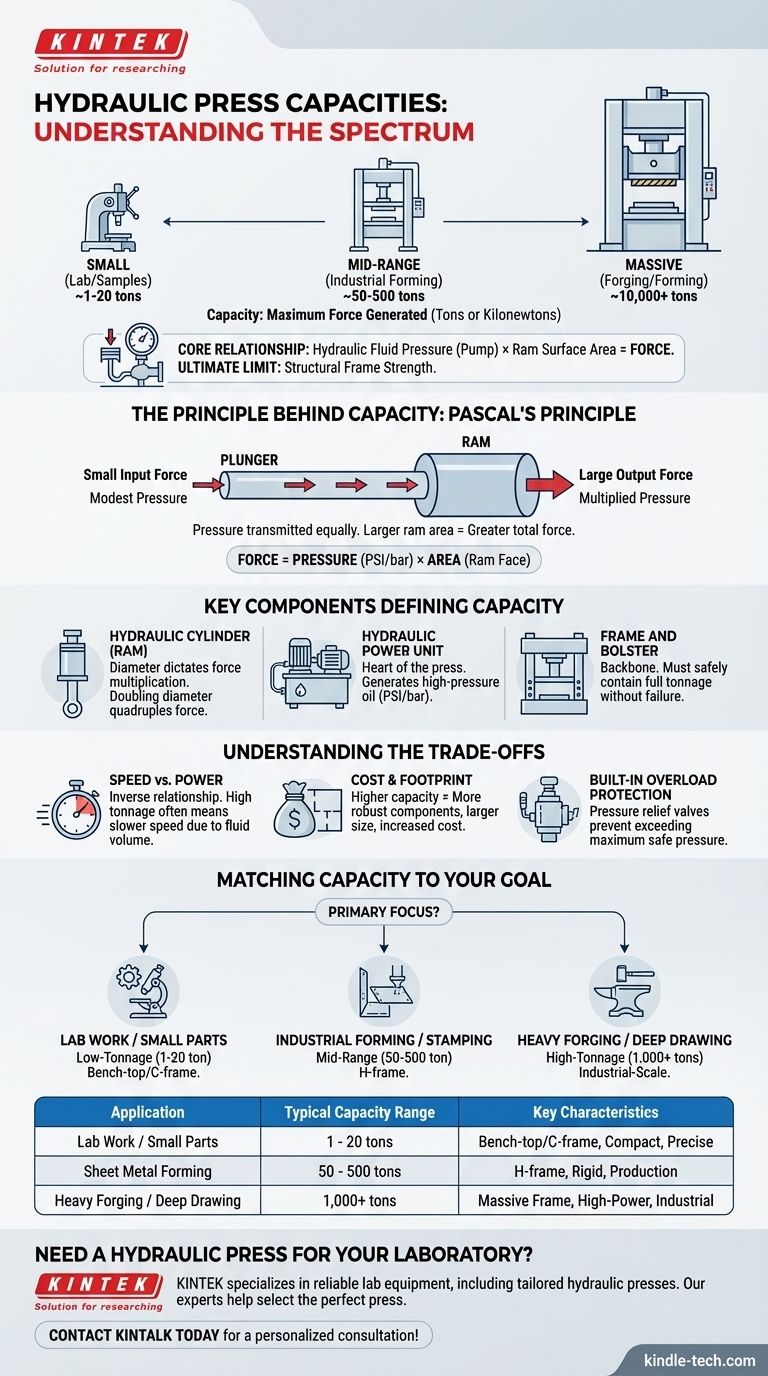

At its core, the capacity of a hydraulic press refers to the maximum force it can generate, which is typically measured in tons or kilonewtons. This capacity is not a single number but a vast spectrum, ranging from small, one-ton bench-top presses used for lab samples to massive industrial machines capable of exerting tens of thousands of tons of force for forging and forming large metal components.

A hydraulic press's capacity is determined by a simple but powerful relationship: the hydraulic fluid pressure applied by the pump and the surface area of the main piston (the ram). The ultimate limit, however, is the structural strength of the machine's frame, which must safely contain this immense force.

The Principle Behind Hydraulic Capacity

A hydraulic press operates on a fundamental law of physics, which allows it to multiply a small input force into a massive output force. Understanding this principle is key to understanding its capacity.

The Role of Pascal's Principle

A hydraulic press consists of two interconnected cylinders of different sizes filled with an incompressible fluid, such as oil. The smaller cylinder is the plunger, and the larger one is the ram.

When a modest force is applied to the plunger, it creates pressure in the fluid. According to Pascal's Principle, this pressure is transmitted equally throughout the entire fluid system, acting on every surface.

Because the surface area of the ram is much larger than the plunger, the same pressure results in a much greater total force being exerted by the ram. This is the essence of hydraulic force multiplication.

How Force is Determined

The final output force (the press's capacity) is a direct result of two factors:

- System Pressure: Generated by the hydraulic power unit and pump. This is measured in pounds per square inch (PSI) or bar.

- Ram Area: The surface area of the ram's face.

The relationship is straightforward: Force = Pressure × Area. A larger ram or a higher-pressure pump will result in a higher-capacity press.

Key Components That Define Capacity

While the principle is simple, a press's real-world capacity is defined by the capabilities and limitations of its physical components.

The Hydraulic Cylinder (Ram)

The diameter of the ram is the most significant factor in force multiplication. Doubling the ram's diameter quadruples its surface area, and therefore, it quadruples the potential output force for a given system pressure.

The Hydraulic Power Unit

This unit, which includes the motor and pump, is the heart of the press. It is responsible for delivering the high-pressure oil that drives the system. The maximum pressure the power unit can consistently and safely generate dictates the "Pressure" side of the force equation.

The Frame and Bolster

The frame is the backbone of the press. It must be engineered to withstand the full tonnage the hydraulic system can generate without flexing or failing. A press rated for 100 tons must have a frame that can safely contain 100 tons of force, making structural integrity a critical limiting factor of its true capacity.

Understanding the Trade-offs

Selecting a press isn't just about choosing the highest tonnage. Capacity comes with important trade-offs that affect performance and cost.

Speed vs. Power

There is often an inverse relationship between a press's speed and its maximum force. Generating extremely high pressure requires significant energy, and the volume of fluid needed to move a large ram means high-tonnage presses are often slower than their lower-tonnage counterparts.

Cost and Footprint

Higher capacity demands more robust components. A stronger frame, a larger ram, and a more powerful hydraulic unit all increase the machine's material cost, complexity, and physical size. More tonnage requires more steel and a larger footprint on the shop floor.

Built-in Overload Protection

A key advantage of hydraulic systems is their inherent overload protection. Pressure relief valves prevent the system from exceeding its designed maximum pressure, protecting both the workpiece and the machine's structural components from damage. This feature ensures the press operates safely within its stated capacity.

Matching Capacity to Your Goal

The right capacity is entirely dependent on your application. Over-specifying is wasteful, while under-specifying will lead to failure.

- If your primary focus is lab work or small parts assembly: A low-tonnage (1-20 ton) bench-top or C-frame press provides sufficient force with a small footprint.

- If your primary focus is industrial sheet metal forming or stamping: A mid-range (50-500 ton) H-frame press offers the rigidity and power needed for consistent production.

- If your primary focus is heavy forging, deep drawing, or molding: You will need a high-tonnage (1,000+ tons) press where the frame's integrity and the power unit's reliability are the most critical factors.

Ultimately, choosing the right capacity means understanding that the press is a complete system where the power unit, cylinder size, and frame strength must all work in harmony.

Summary Table:

| Application | Typical Capacity Range | Key Characteristics |

|---|---|---|

| Lab Work / Small Parts | 1 - 20 tons | Bench-top or C-frame, compact, precise |

| Sheet Metal Forming / Stamping | 50 - 500 tons | H-frame, rigid, suitable for production |

| Heavy Forging / Deep Drawing | 1,000+ tons | Massive frame, high-power unit, industrial-scale |

Need a Hydraulic Press for Your Laboratory?

Choosing the correct capacity is critical for your project's success and safety. KINTEK specializes in providing reliable lab equipment, including hydraulic presses tailored to your specific needs—from compact bench-top models for sample preparation to robust systems for advanced material testing.

Our experts can help you select the perfect press based on your required force, application, and workspace.

Boost your lab's capabilities with the right equipment. Contact KINTALK today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis