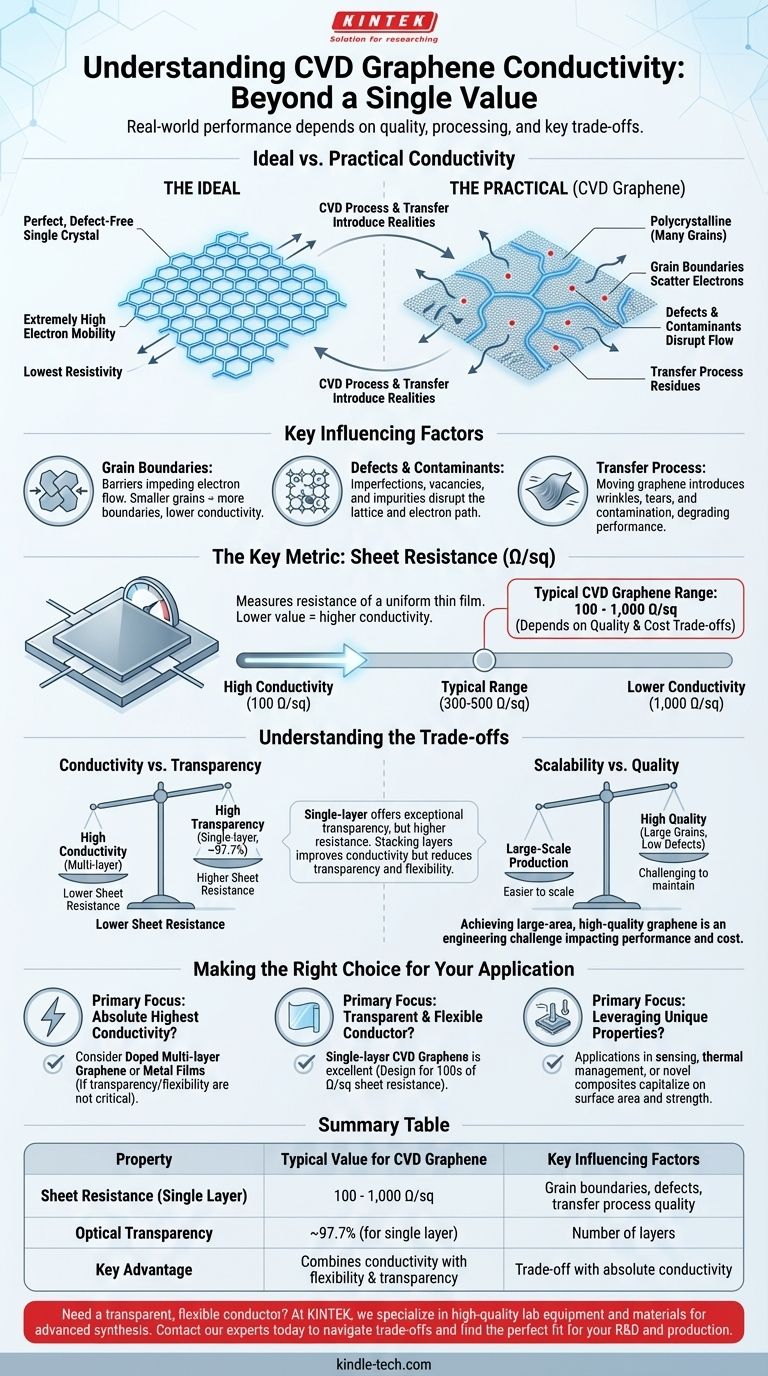

The electrical conductivity of CVD graphene is not a single, fixed value but a range determined by its quality and processing. While theoretically the most conductive material known, the practical conductivity of graphene produced via Chemical Vapor Deposition (CVD) is influenced by factors like grain boundaries, defects, and the transfer process. Its performance is most accurately measured by sheet resistance, which typically falls between 100 and 1,000 Ohms per square (Ω/sq) for a single layer.

The core issue is not simply the conductivity of CVD graphene, but understanding the trade-off between its excellent transparency and flexibility versus a conductivity that is good, but often lower than traditional materials like Indium Tin Oxide (ITO). Its true value lies in applications where this combination of properties is essential.

Why Real-World Conductivity Varies

Graphene's reputation as a "super-material" comes from the properties of a perfect, suspended, single-crystal flake. CVD graphene, designed for large-area production, introduces practical realities that modify these ideal properties.

The Ideal vs. The Practical

Theoretically, defect-free graphene has exceptionally high electron mobility, leading to extremely low resistivity. This is the source of its fame as the world's most conductive material.

However, CVD graphene is polycrystalline, meaning it is composed of many small, single-crystal "grains" that are stitched together during the growth process.

The Impact of Grain Boundaries

The boundaries between these crystal grains act as barriers that scatter electrons, impeding their flow. The smaller the grains, the more boundaries there are, and the lower the overall conductivity of the film.

Achieving large, single-crystal grains over a large area is a primary goal of advanced CVD research, as it directly improves electrical performance.

Defects and Contaminants

Any imperfection in the honeycomb lattice, such as missing atoms (vacancies) or impurities from the chemical process, can disrupt electron flow.

Furthermore, residues from the crucial step of transferring the graphene film from its growth substrate (typically copper) to a target substrate (like glass or plastic) are a major source of degraded conductivity.

Understanding the Key Metric: Sheet Resistance

For a two-dimensional material like graphene, a more practical measure than bulk conductivity is sheet resistance.

What is Sheet Resistance?

Sheet resistance, measured in Ohms per square (Ω/sq), describes the electrical resistance of a thin film of a uniform thickness. It is the standard metric used in industries that produce or use transparent conductive films.

A lower sheet resistance value indicates higher conductivity.

Typical Values for CVD Graphene

High-quality, research-grade single-layer CVD graphene can achieve a sheet resistance of around 100-300 Ω/sq.

More common, commercially produced large-area films may have a higher sheet resistance, often in the range of 400-1,000 Ω/sq, depending on the quality and cost trade-offs.

Understanding the Trade-offs

Choosing CVD graphene requires balancing its unique advantages against its practical limitations. It is not a universal replacement for all conductive materials.

The Critical Transfer Process

The process of moving the one-atom-thick graphene film from its copper growth foil to a final substrate is a significant challenge. This delicate step can introduce wrinkles, tears, and contamination, all of which negatively impact the final conductivity.

Conductivity vs. Transparency

Single-layer graphene offers exceptional optical transparency (absorbing only ~2.3% of visible light), but has the highest resistance.

Stacking multiple layers of graphene will decrease the sheet resistance (improve conductivity) but at the direct cost of reduced transparency and potentially lower flexibility.

Scalability vs. Quality

While CVD is hailed as the most promising method for large-scale production, there is often a trade-off between the size of the graphene sheet and its quality. Maintaining very low defect densities and large grain sizes over meter-scale production runs is a significant engineering challenge that impacts final performance and cost.

Making the Right Choice for Your Application

To decide if CVD graphene is the right material, you must evaluate its performance in the context of your specific requirements.

- If your primary focus is the absolute highest conductivity: Doped multi-layer graphene or traditional thin metal films may be more suitable, especially if transparency and flexibility are not critical.

- If your primary focus is a transparent and flexible conductor: Single-layer CVD graphene is an outstanding candidate, but you must design your device to function with a sheet resistance in the hundreds of Ω/sq.

- If your primary focus is leveraging its unique properties: Applications in sensing, thermal management, or creating novel composite materials can capitalize on graphene's large surface area and mechanical strength, where conductivity is a secondary, albeit useful, feature.

Ultimately, you must evaluate CVD graphene based on its unique balance of properties, not on a single, idealized metric.

Summary Table:

| Property | Typical Value for CVD Graphene | Key Influencing Factors |

|---|---|---|

| Sheet Resistance (Single Layer) | 100 - 1,000 Ω/sq | Grain boundaries, defects, transfer process quality |

| Optical Transparency | ~97.7% (for single layer) | Number of layers |

| Key Advantage | Combines conductivity with flexibility & transparency | Trade-off with absolute conductivity |

Need a transparent, flexible conductor for your next-generation device?

At KINTEK, we specialize in providing high-quality lab equipment and materials, including solutions for advanced material synthesis and characterization. Our expertise can help you navigate the trade-offs of materials like CVD graphene to find the perfect fit for your specific application—whether it's for flexible electronics, sensors, or composite materials.

Contact our experts today to discuss how we can support your R&D and production goals with reliable equipment and consumables tailored to your laboratory's needs.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Glassy Carbon Sheet RVC for Electrochemical Experiments

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What is plasma CVD? Unlock Low-Temperature Thin Film Deposition for Sensitive Materials

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What are the advantages of plasma enhanced CVD? Enable Low-Temperature, High-Quality Thin Film Deposition