At its core, a hydraulic press is constructed from three fundamental systems. These are the mainframe which provides the structural foundation, the power system that generates pressure, and the hydraulic control system that directs the force. These components work in unison, using the principle of fluid pressure to generate immense mechanical force from a small initial effort.

The entire operation of a hydraulic press hinges on a simple physical principle: Pascal's Law. By using an incompressible fluid to transfer pressure from a small cylinder to a larger one, the machine multiplies the initial force, creating the power needed for heavy-duty industrial tasks.

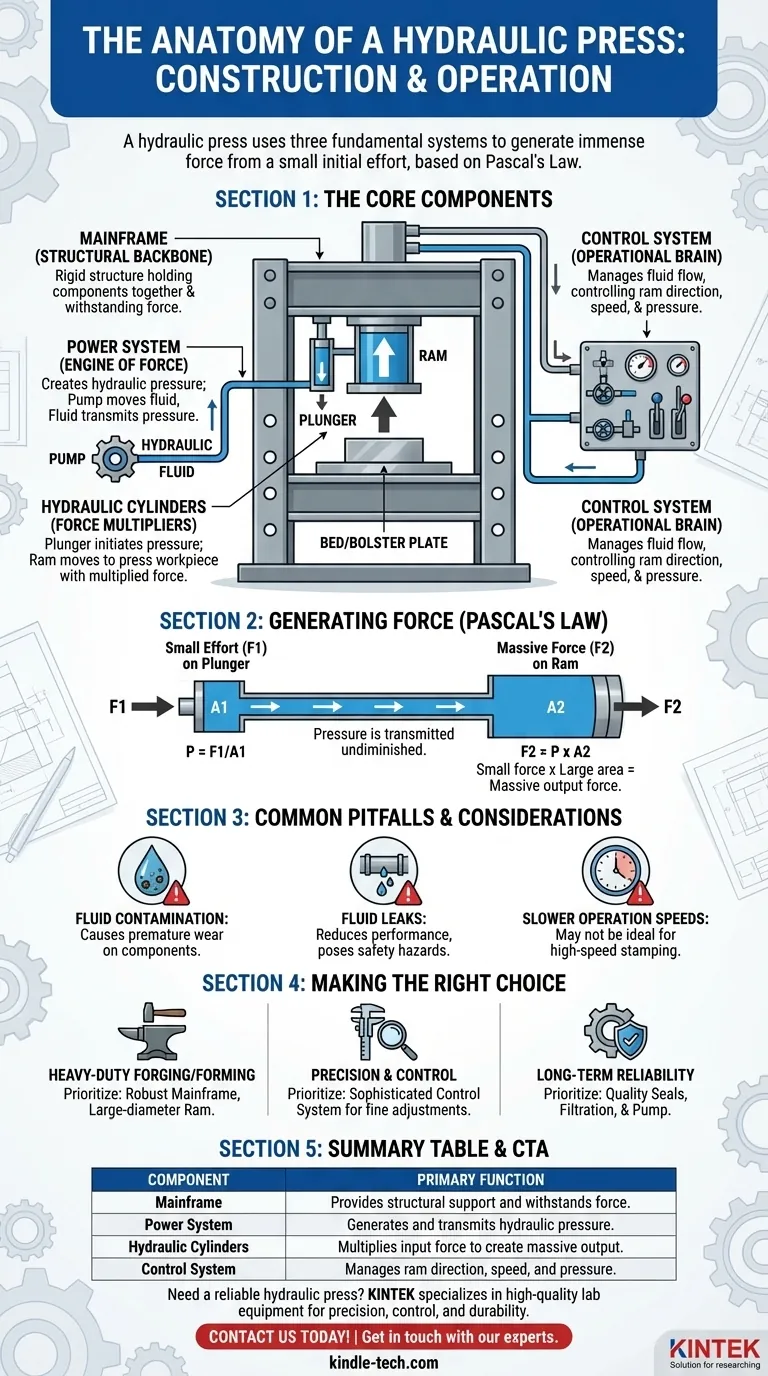

The Core Components of a Hydraulic Press

To understand how a hydraulic press functions, we must first examine its key parts. Each component serves a distinct and critical purpose in the generation and application of force.

The Mainframe (The Structural Backbone)

The mainframe is the rigid, heavy structure that holds all other components together and withstands the immense forces generated during operation.

It typically includes the bed or bolster plate, which is the flat, stable surface that supports the material or workpiece being pressed. The frame's strength is paramount for safety and precision.

The Power System (The Engine of Force)

This system is responsible for creating the hydraulic pressure. It is not a single part but a collection of interconnected components.

A pump is the prime mover, responsible for forcing the hydraulic fluid (typically oil) into the system. It's the starting point of the entire pressing action.

The hydraulic fluid is the lifeblood of the machine. It is an incompressible liquid used to transmit pressure efficiently from one point to another within the sealed system.

The Hydraulic Cylinders (The Force Multipliers)

The press contains two primary interconnected cylinders of different sizes, which are the heart of the force multiplication.

The smaller cylinder is known as the plunger. When hydraulic fluid is forced into it, it initiates the pressure.

The larger cylinder is the ram. This is the component that moves to press the workpiece. Because its surface area is much larger than the plunger's, the force exerted by the ram is proportionally greater.

The Control System (The Operational Brain)

The hydraulic control system, composed of valves, pipes, and controls, manages the flow of hydraulic fluid.

This system allows the operator to control the direction, speed, and pressure of the ram, enabling precise and repeatable operations.

How These Components Generate Force

The genius of the hydraulic press is not in its complexity, but in its elegant application of a fundamental physics principle.

Applying Pascal's Law

The system operates on Pascal's Law, which states that pressure applied to an enclosed fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

From Small Effort to Massive Force

When the pump moves fluid into the small plunger cylinder, it creates pressure (Pressure = Force / Area). This same pressure is transmitted through the fluid to the large ram cylinder.

Because the ram has a much larger surface area, the resulting output force (Force = Pressure x Area) is significantly multiplied. A small force on the plunger results in a massive force at the ram.

Common Pitfalls and Considerations

While powerful and versatile, the construction of a hydraulic press brings inherent operational challenges that require attention.

Risk of Fluid Contamination

The hydraulic system is a closed loop, making it highly sensitive to contaminants like dirt or metal particles in the fluid. Contamination can cause premature wear on pumps, valves, and seals, leading to failure.

Potential for Fluid Leaks

The system operates under extremely high pressure. Over time, seals and hoses can degrade, creating a risk of hydraulic fluid leaks. This not only reduces performance but also poses safety and environmental hazards.

Slower Operation Speeds

Compared to purely mechanical presses, hydraulic presses can have slower cycle times. The time it takes for the fluid to move and build pressure means they may not be ideal for very high-speed, high-volume stamping operations.

Making the Right Choice for Your Application

Understanding the construction of a hydraulic press allows you to evaluate which features are most critical for your specific goals.

- If your primary focus is heavy-duty forging or forming: Prioritize a machine with an exceptionally robust mainframe and a large-diameter ram to handle maximum force without deflection.

- If your primary focus is precision and control: The sophistication of the hydraulic control system is paramount, allowing for fine adjustments to pressure, speed, and stroke depth.

- If your primary focus is long-term reliability and low maintenance: Focus on the quality of the seals, filtration system, and pump to minimize the risks of leaks and contamination.

By understanding how these core components are constructed and interact, you can effectively leverage the immense power of hydraulic force for your work.

Summary Table:

| Component | Primary Function |

|---|---|

| Mainframe | Provides structural support and withstands force. |

| Power System (Pump & Fluid) | Generates and transmits hydraulic pressure. |

| Hydraulic Cylinders (Plunger & Ram) | Multiplies the input force to create a massive output force. |

| Control System | Manages the direction, speed, and pressure of the ram. |

Need a reliable hydraulic press for your laboratory or production line? KINTEK specializes in high-quality lab equipment, including robust hydraulic presses designed for precision, control, and durability. Our machines are built to handle your specific forging, forming, or material testing needs with exceptional reliability. Contact us today to find the perfect press for your application and experience the KINTEK difference in performance and support. Get in touch with our experts now!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.