The fundamental difference between a ball mill and a pebble mill is the type of grinding media they use. A ball mill uses steel or other metal balls to crush material, while a pebble mill uses natural stone pebbles or manufactured ceramic balls. This single distinction dictates every other difference between them, from their construction to their most appropriate applications.

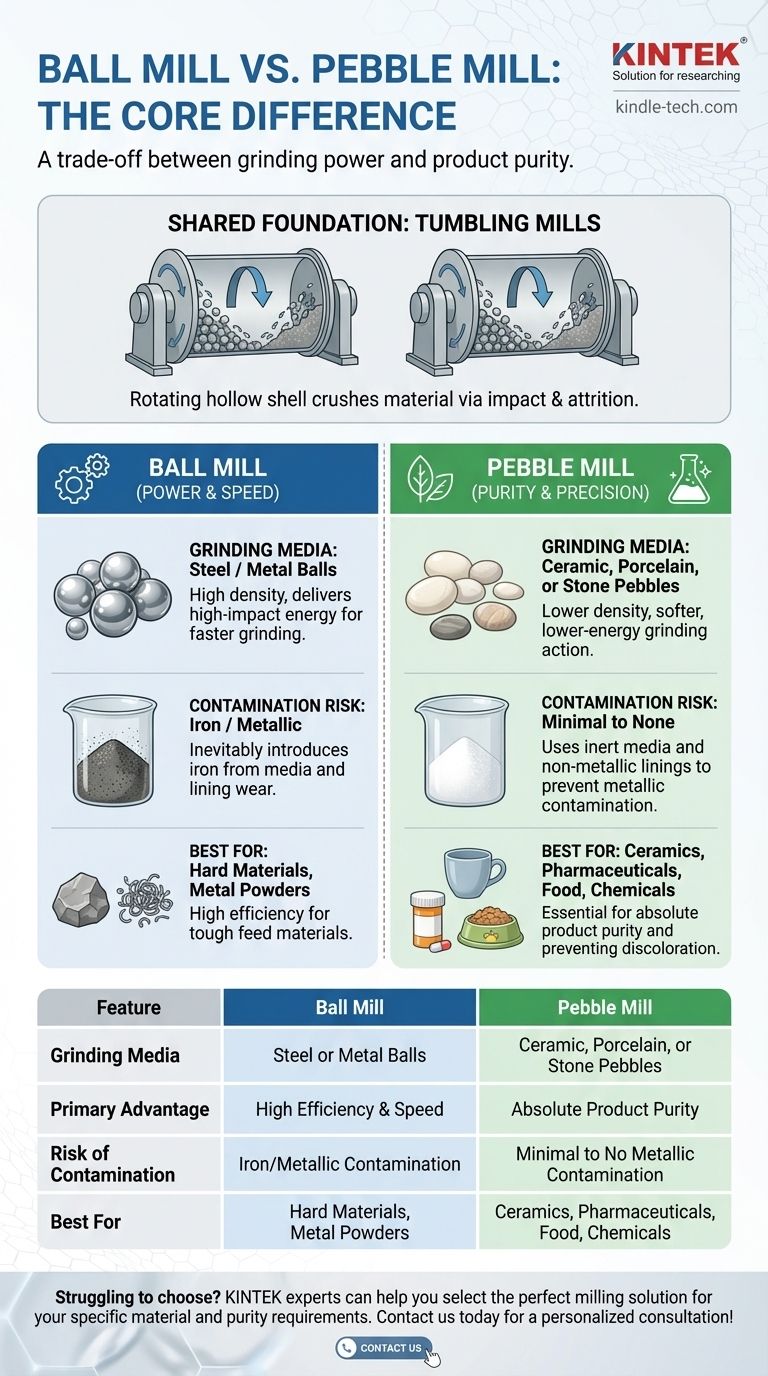

The choice between a ball mill and a pebble mill is a direct trade-off between grinding power and product purity. Ball mills offer higher efficiency and speed, whereas pebble mills are essential for applications where preventing metallic contamination is non-negotiable.

The Shared Foundation: Tumbling Mills

Before examining their differences, it's crucial to understand that both ball and pebble mills belong to the same family of equipment known as tumbling mills.

How They Work

Both mills consist of a hollow cylindrical shell that rotates on its axis. The material to be ground is loaded into this shell along with the grinding media (either balls or pebbles).

As the shell rotates, the media is lifted up the side and then tumbles or cascades back down. The material is crushed and ground through the combination of impact (media falling onto the material) and attrition (media rubbing against the material and the mill lining).

The Defining Difference: Grinding Media

The choice of media is what truly separates these two machines and defines their roles in industrial processes.

The Ball Mill: Steel Media for Power

A ball mill is defined by its use of steel grinding media. These can be forged steel, chrome steel, or stainless steel balls.

Because steel is very dense, it delivers high-impact energy. This makes ball mills highly efficient at grinding, capable of breaking down harder materials and achieving a fine particle size relatively quickly.

The Pebble Mill: Ceramic or Stone for Purity

A pebble mill uses non-metallic grinding media. This is traditionally natural, hard-wearing stones like flint or silica pebbles.

More commonly today, pebble mills use manufactured ceramic media, such as high-density alumina, zirconia, or porcelain. This media is less dense than steel, resulting in a "softer," lower-energy grinding action.

Understanding the Trade-offs

The choice between steel and ceramic/stone media creates a clear set of advantages and disadvantages for each mill type.

Product Contamination

This is the single most important factor. During the grinding process, the media and the mill's inner lining inevitably wear down, introducing tiny particles into the product.

With a ball mill, this results in iron contamination from the steel balls. For many applications, like producing metal powders, this is irrelevant. However, for industries like high-purity ceramics, pharmaceuticals, or food products, iron contamination is unacceptable as it can cause discoloration or impurities.

Pebble mills, using inert media, are specifically designed to prevent metallic contamination, ensuring the final product remains pure.

Grinding Efficiency and Speed

Due to the higher density of steel balls, ball mills grind faster and more aggressively than pebble mills of a similar size. They can handle tougher feed materials and require shorter processing times.

Pebble mills have a lower grinding efficiency due to the lower mass of the media. Achieving the same level of fineness may require a larger mill or significantly longer grinding cycles.

Mill Construction and Lining

The mill's internal lining must be compatible with the grinding media to prevent contamination from the shell itself.

Ball mills are typically lined with hard metals like chrome-moly steel or wear-resistant rubber. In contrast, pebble mills must be lined with non-metallic materials like silica blocks, porcelain, or high-alumina bricks to maintain the integrity and purity of the product.

Making the Right Choice for Your Goal

Selecting the correct mill is not about which one is "better," but which is appropriate for the specific material and desired outcome.

- If your primary focus is throughput, speed, and grinding hard materials: A ball mill is the superior choice due to the high-impact energy of steel media.

- If your primary focus is absolute product purity and avoiding iron contamination: A pebble mill is the only viable option.

- If you are processing light-colored ceramics, paints, pharmaceuticals, or food-grade materials: The pebble mill is the industry standard to prevent discoloration and ensure safety.

Ultimately, your decision hinges on balancing the need for grinding efficiency against the critical requirement for product purity.

Summary Table:

| Feature | Ball Mill | Pebble Mill |

|---|---|---|

| Grinding Media | Steel or Metal Balls | Ceramic, Porcelain, or Stone Pebbles |

| Primary Advantage | High Efficiency & Speed | Absolute Product Purity |

| Risk of Contamination | Iron/Metallic Contamination | Minimal to No Metallic Contamination |

| Best For | Hard Materials, Metal Powders | Ceramics, Pharmaceuticals, Food, Chemicals |

Struggling to choose between grinding power and product purity? KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you select the perfect milling solution for your specific material and purity requirements. Contact us today for a personalized consultation!

Visual Guide

Related Products

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- Laboratory Horizontal Planetary Ball Mill Milling Machine

People Also Ask

- What is a planetary milling machine used for? Achieve Nano-Scale Grinding for Hard & Soft Materials

- What are the advantages of planetary ball milling? Achieve High-Energy Grinding and Material Synthesis

- What is the working principle of planetary ball mill? Unlock High-Energy Grinding for Nanoscale Results

- What is the principle of planetary ball mill? Achieve Rapid, High-Energy Grinding for Your Materials

- What is a planetary ball mill? Achieve Rapid, High-Energy Grinding for Advanced Materials