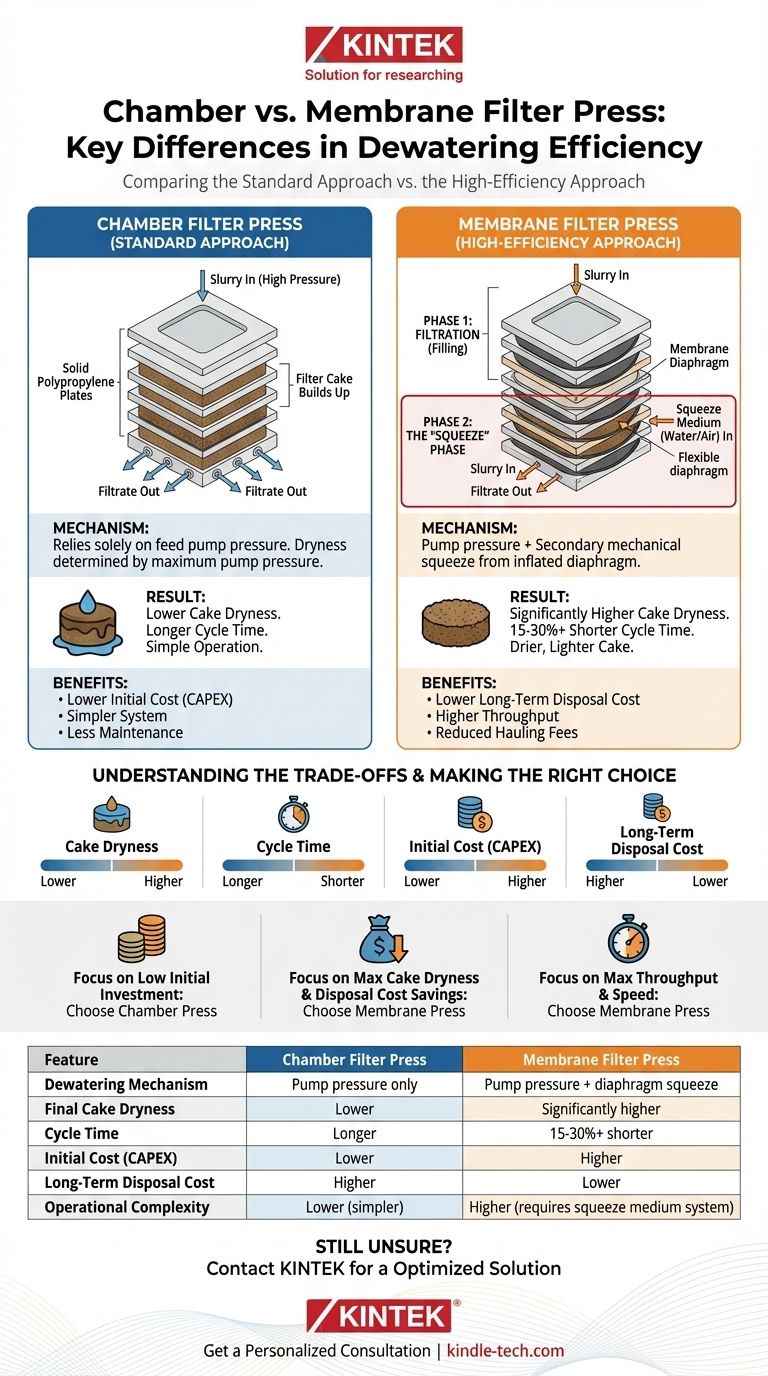

At its core, the difference between a chamber and a membrane filter press lies in the design of their filter plates and the resulting dewatering process. A standard chamber press relies solely on the feed pump's pressure to dewater the slurry. A membrane filter press, however, adds a secondary "squeeze" phase, where a flexible diaphragm inflates to physically press the filter cake, forcing out significantly more liquid.

While both technologies separate solids from liquids, the choice between them is a critical decision balancing initial cost against operational efficiency. Chamber presses offer simplicity and lower capital expenditure, whereas membrane presses provide drier cakes, shorter cycle times, and lower long-term disposal costs.

How a Chamber Filter Press Works (The Standard Approach)

A chamber filter press, also known as a recessed plate filter press, is the foundational design in pressure filtration. Its operation is straightforward and robust.

The Filtration Mechanism

The press consists of a series of solid polypropylene plates with a recessed area on each side. When pressed together, the recesses of two adjacent plates form a hollow space, or chamber, where the filtration occurs.

The Dewatering Process

Slurry is pumped into these chambers at high pressure. The liquid, or filtrate, passes through a filter cloth placed over each plate and exits through ports. The solid particles are retained, gradually building up and filling the chamber to form a filter cake.

Resulting Cake Properties

The process stops when the chambers are full of solids and the feed pump can no longer force liquid through the packed cake. The dryness of the final cake is determined entirely by the pump's maximum pressure and the permeability of the solids.

How a Membrane Filter Press Works (The High-Efficiency Approach)

A membrane filter press represents an evolution of the chamber press, designed to achieve superior dewatering by adding a mechanical squeeze.

The Two-Phase Process

The press uses a combination of standard chamber plates and special membrane plates. These membrane plates feature a flexible, impermeable diaphragm mounted over a solid core. The initial filtration phase is identical to a chamber press, filling the chambers with a filter cake.

The Critical "Squeeze" Phase

However, the filtration phase is stopped before the cake is fully dewatered. At this point, the slurry feed is shut off, and a medium—typically water or compressed air—is pumped into a cavity behind the flexible membrane.

This causes the diaphragm to inflate, physically squeezing the filter cake in the chamber from both sides. This mechanical pressure efficiently forces out additional filtrate that the feed pump alone could not remove.

Resulting Cake Properties

This squeeze phase results in a filter cake with a significantly higher percentage of solids and lower moisture content. The final cake is often crumbly and much lighter than one from a chamber press.

Understanding the Trade-offs

Choosing the correct press technology requires a clear-eyed view of the trade-offs between capital cost and operational performance.

Cake Dryness and Disposal Costs

A membrane press consistently produces a drier filter cake. For industries where cake is transported for disposal, this reduction in water weight and volume can lead to substantial savings in hauling and landfill fees.

Cycle Time and Throughput

Because the filtration phase can be stopped earlier, the overall cycle time of a membrane press is often much shorter (15-30% or more) than a chamber press for the same application. This results in higher throughput and greater processing capacity for a given size press.

Initial Investment (CAPEX)

Chamber filter presses are mechanically simpler. They have fewer components, making their upfront purchase price significantly lower than a comparably sized membrane press.

Operational Complexity (OPEX)

Membrane presses require an additional system to supply the squeeze medium (e.g., a water skid or air compressor). The membranes themselves are also wear items that will eventually need replacement, adding to long-term maintenance costs.

Making the Right Choice for Your Process

The ideal filter press depends entirely on your specific operational and financial priorities.

- If your primary focus is minimizing initial investment: A chamber filter press is the most straightforward and cost-effective option for basic solid-liquid separation.

- If your primary focus is maximizing cake dryness to reduce disposal costs: A membrane filter press is the superior choice, as the squeeze phase will dramatically lower cake weight and volume.

- If your primary focus is maximizing throughput and process speed: A membrane filter press offers significantly shorter cycle times, allowing you to process more slurry in less time.

Ultimately, your decision should be based on a clear analysis of your total cost of ownership, weighing the upfront savings of a chamber press against the long-term operational efficiencies of a membrane press.

Summary Table:

| Feature | Chamber Filter Press | Membrane Filter Press |

|---|---|---|

| Dewatering Mechanism | Pump pressure only | Pump pressure + diaphragm squeeze |

| Final Cake Dryness | Lower | Significantly higher |

| Cycle Time | Longer | 15-30%+ shorter |

| Initial Cost (CAPEX) | Lower | Higher |

| Long-Term Disposal Cost | Higher | Lower |

| Operational Complexity | Lower (simpler) | Higher (requires squeeze medium system) |

Still unsure which filter press is right for your operation?

KINTEK specializes in providing robust and efficient laboratory equipment and consumables, including filtration solutions. Our experts can help you analyze your specific slurry, throughput requirements, and budget to determine the optimal technology for your lab's needs.

Contact us today via the form below to discuss your application and discover how KINTEK can enhance your dewatering process, improve efficiency, and reduce your total cost of ownership.

Get a Personalized Consultation

Visual Guide

Related Products

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Warm Isostatic Press for Solid State Battery Research

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

People Also Ask

- What is sputtering yield? Master the Key to Efficient Thin Film Deposition

- What is the temperature of a pyrolysis reactor? Master Thermal Control for Optimal Product Yields

- Why is debinding important? The Critical Step for Strong, Dense Metal and Ceramic Parts

- What is brazing in safety? Managing Toxic Fumes, Fire, and Chemical Hazards

- Why are anaerobic glove boxes and nitrogen purging systems required for SRB experiments? Ensure Optimal Oxygen Exclusion

- Does pyrolysis require a catalyst? Unlock Higher-Value Fuels from Waste

- Is pyrolysis safe for the Environment? A Guide to Responsible Waste Conversion

- What is the hottest temperature a furnace can be? Exploring Limits from 3,000°C+ to Your Application