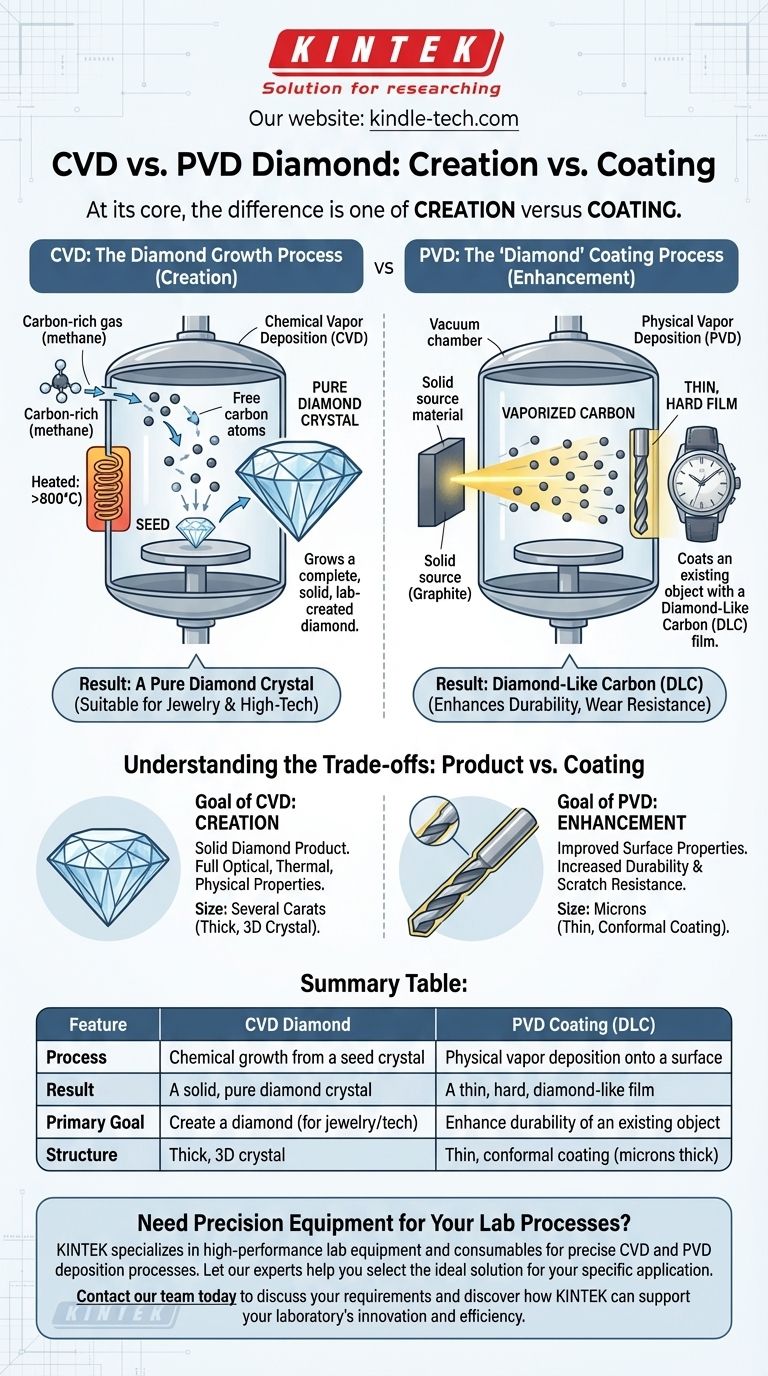

At its core, the difference is one of creation versus coating. Chemical Vapor Deposition (CVD) is a process used to grow a complete, solid, lab-created diamond. In contrast, Physical Vapor Deposition (PVD) is a process used to coat an existing object with a very thin, hard film of Diamond-Like Carbon (DLC), which is not a true diamond.

The most critical distinction is this: CVD creates the product itself—a real diamond crystal—while PVD applies a functional enhancement—a durable surface coating—onto a different product. You purchase a CVD diamond, but you purchase an object with a PVD coating.

What is CVD? The Diamond Growth Process

Chemical Vapor Deposition (CVD) is one of the primary methods for creating lab-grown diamonds. The process is designed to replicate the conditions that allow carbon atoms to form the crystal structure of a diamond.

The "Seed" and the Chamber

The process begins by placing a tiny, pre-existing diamond crystal, known as a "seed," inside a vacuum chamber.

The Chemical Reaction

The chamber is then filled with carbon-rich gases (like methane) and heated to extremely high temperatures, often over 800°C. This high heat breaks down the gas molecules, freeing the carbon atoms.

The Result: A Pure Diamond Crystal

These free carbon atoms are drawn to the cooler diamond seed and deposit onto it, layer by layer. They arrange themselves into the same rigid crystal lattice, effectively "growing" the original seed into a much larger, chemically pure diamond.

What is PVD? The "Diamond" Coating Process

Physical Vapor Deposition (PVD) is fundamentally a surface treatment technology. It is not used to create gemstones but to improve the surface properties of other materials, like metal tools, watch cases, or engine components.

A Line-of-Sight Process

PVD is a line-of-sight process that takes place in a vacuum. A solid source material, typically graphite, is vaporized using methods like sputtering or thermal evaporation.

Physical Deposition, Not Chemical Growth

This vaporized carbon then travels in a straight line and condenses onto the target object, forming a very thin, smooth, and hard film. There is no foundational chemical reaction with the substrate itself.

The Result: Diamond-Like Carbon (DLC)

The resulting film is called Diamond-Like Carbon (DLC). While it possesses some of the desirable properties of diamond—namely high hardness and low friction—it is not a crystalline diamond. It is an amorphous layer of carbon atoms, not a gemstone.

Understanding the Trade-offs: Product vs. Coating

The choice between these technologies is not a choice between two types of diamond. It is a choice between creating a diamond product or applying a protective coating to a different product.

The Goal of CVD: Creation

CVD is used when the final product is intended to be a solid diamond. The outcome is a monolithic material with the full optical, thermal, and physical properties of a diamond, suitable for use in jewelry or high-tech industrial applications.

The Goal of PVD: Enhancement

PVD is used to enhance the surface of an existing component. The goal is to make an object more resistant to wear, scratches, or corrosion. The underlying object retains its original properties, but its surface is significantly more durable.

Thickness and Structure

A CVD diamond can be grown to several carats in size, resulting in a thick, three-dimensional crystal. A PVD coating is exceptionally thin, often measured in microns (thousandths of a millimeter), and conforms to the shape of the object it covers.

Making the Right Choice for Your Application

Your goal will determine which of these terms is relevant to you.

- If your primary focus is acquiring a lab-grown gemstone: You are looking for a CVD diamond. The term PVD is not relevant to your search for a diamond.

- If your primary focus is improving the durability of a tool or component: You are seeking a PVD process that applies a Diamond-Like Carbon (DLC) coating.

- If your primary focus is technical clarity: Remember that CVD grows a pure diamond crystal, while PVD applies a thin, diamond-like film.

Understanding this fundamental difference between creation and coating empowers you to correctly identify the technology that meets your specific need.

Summary Table:

| Feature | CVD Diamond | PVD Coating (DLC) |

|---|---|---|

| Process | Chemical growth from a seed crystal | Physical vapor deposition onto a surface |

| Result | A solid, pure diamond crystal | A thin, hard, diamond-like film |

| Primary Goal | Create a diamond (for jewelry/tech) | Enhance durability of an existing object |

| Structure | Thick, 3D crystal | Thin, conformal coating (microns thick) |

Need Precision Equipment for Your Lab Processes?

Whether you're developing advanced materials with CVD or enhancing component durability with PVD coatings, the right equipment is critical for success. KINTEK specializes in high-performance lab equipment and consumables, providing the reliable tools you need for precise deposition processes.

Let our experts help you select the ideal solution for your specific application. Contact our team today to discuss your requirements and discover how KINTEK can support your laboratory's innovation and efficiency.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

People Also Ask

- What are the challenges of carbon nanotubes? Overcoming Production and Integration Hurdles

- Why are carbon nanotubes important in industry? Unlocking Next-Generation Material Performance

- What is the floating catalyst method? A Guide to High-Yield CNT Production

- What are the methods of producing CNT? Scalable CVD vs. High-Purity Lab Techniques

- How does chirality affect carbon nanotubes? It Determines If They Are Metal or Semiconductor