At their core, the difference between a hydraulic and a mechanical press lies in how they generate force. A hydraulic press uses pressurized fluid (typically oil) to move a piston and exert a constant force, while a mechanical press uses a motor-driven flywheel to store energy that is transferred through a crank or eccentric gear system. This fundamental distinction dictates their performance, cost, and ideal applications.

The choice between a hydraulic and mechanical press is not about which is "better," but which is right for the job. Hydraulic presses excel in force control and versatility, while mechanical presses dominate in speed and high-volume precision.

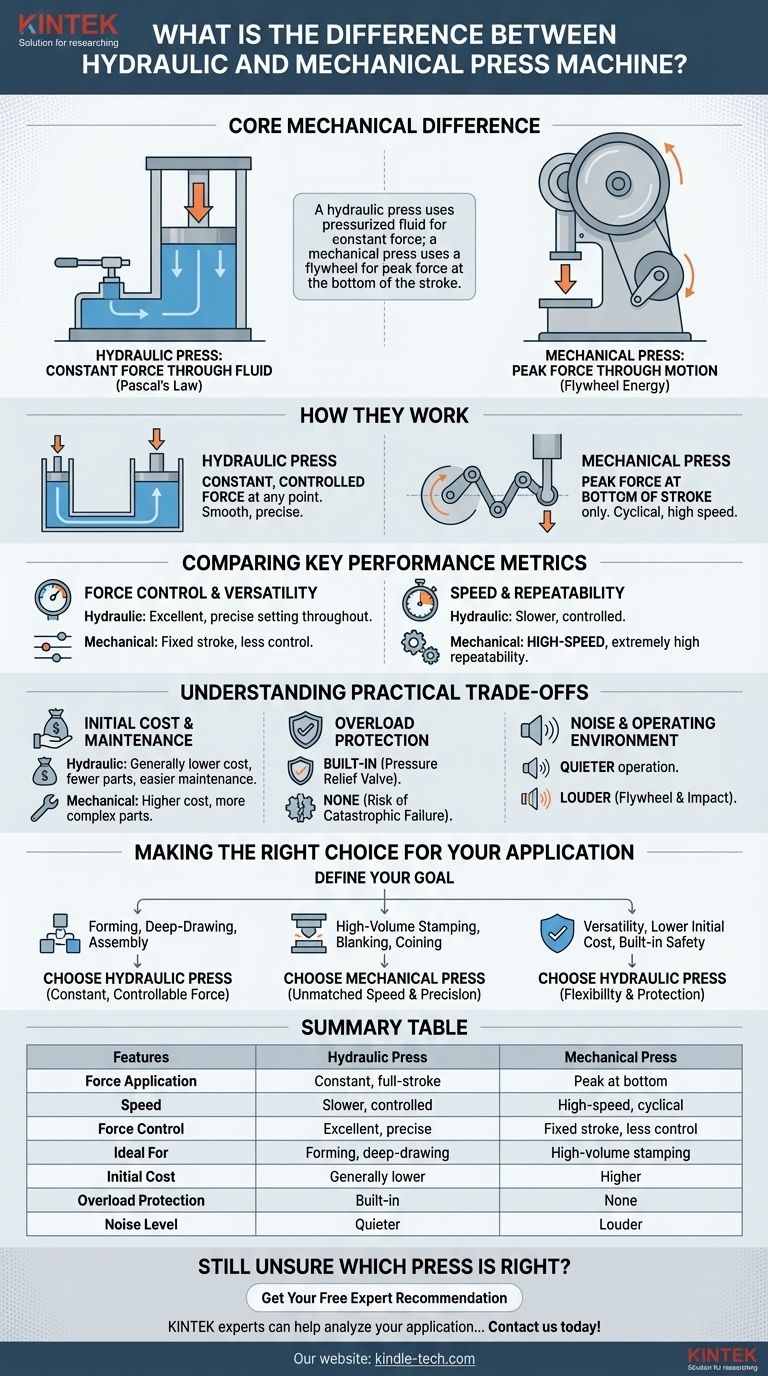

How They Work: The Core Mechanical Difference

Understanding the mechanism behind each press is the key to understanding their respective strengths and weaknesses. Each design is purpose-built for different types of work.

The Hydraulic Press: Constant Force Through Fluid

A hydraulic press operates on the principle of Pascal's Law. A pump moves hydraulic fluid into a cylinder, pushing against a piston.

This design allows the press to generate its full rated force at any point in the piston's stroke. The force is smooth, controlled, and constant from the top to the bottom of the press action.

The Mechanical Press: Peak Force Through Motion

A mechanical press uses a motor to spin a large, heavy flywheel, which stores kinetic energy. When the press is activated, a clutch connects the flywheel to a crankshaft that drives the ram up and down.

Crucially, a mechanical press only achieves its maximum rated tonnage at the very bottom of its stroke. The force is not constant, but instead follows a curve as the crank rotates.

Comparing Key Performance Metrics

The differing mechanics of each press type lead to significant differences in how they perform under real-world conditions.

Force Control & Versatility

Hydraulic presses offer superior force control. The pressure can be precisely set and maintained throughout the entire stroke, which is ideal for deep-drawing, forming, and molding operations where consistent pressure is critical.

Mechanical presses have a fixed stroke length determined by the crankshaft. While some adjustments are possible, they lack the full-stroke force and variable stroke length inherent to hydraulic designs.

Speed & Repeatability

Mechanical presses are built for speed. Their cyclical motion is much faster than a hydraulic system, making them the standard for high-volume, repetitive tasks like blanking, punching, and coining.

The precision of the mechanical linkage also ensures extremely high repeatability, with the ram returning to the exact same position at the bottom of every stroke.

Understanding the Practical Trade-offs

Beyond raw performance, the day-to-day realities of cost, safety, and maintenance are critical factors in your decision.

Initial Cost & Maintenance

Hydraulic presses are generally less expensive to purchase. Their design is simpler, with fewer moving parts, which also makes them easier and cheaper to maintain over time.

Fewer components directly translates to fewer potential points of failure, contributing to their reputation for durability.

Overload Protection

This is a major advantage for hydraulic presses. They are equipped with pressure relief valves, providing inherent overload protection. The press will simply not exert more force than its set limit, protecting the machine and expensive tooling.

Mechanical presses have no built-in overload protection. If an operator attempts to apply too much force or uses the wrong material thickness, it can lead to catastrophic failure, breaking the frame or dies.

Noise and Operating Environment

The smooth action of a hydraulic system results in significantly quieter operation. The primary noise comes from the motor and pump.

Mechanical presses, with their large rotating flywheels and stamping impact, are inherently much louder and generate more vibration.

Making the Right Choice for Your Application

To select the correct press, you must first define your primary goal.

- If your primary focus is forming, deep-drawing, or assembly: Choose a hydraulic press for its constant, controllable force throughout the entire stroke.

- If your primary focus is high-volume stamping, blanking, or coining: Choose a mechanical press for its unmatched speed and precision repeatability.

- If your primary focus is versatility, lower initial cost, and built-in safety: Choose a hydraulic press for its flexibility and inherent overload protection.

Ultimately, understanding these fundamental differences empowers you to select the press that functions as a true solution for your specific manufacturing goal.

Summary Table:

| Feature | Hydraulic Press | Mechanical Press |

|---|---|---|

| Force Application | Constant, full-stroke force | Peak force at bottom of stroke only |

| Speed | Slower, controlled | High-speed, cyclical |

| Force Control | Excellent, precise pressure setting | Fixed stroke, less control |

| Ideal For | Forming, deep-drawing, molding | High-volume stamping, blanking, coining |

| Initial Cost | Generally lower | Higher |

| Overload Protection | Built-in (pressure relief valve) | None (risk of catastrophic failure) |

| Noise Level | Quieter | Louder (flywheel and impact noise) |

Still Unsure Which Press is Right for Your Lab or Production Line?

KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you analyze your specific application—whether it's precision forming, high-volume stamping, or material testing—to recommend the perfect hydraulic or mechanical press.

Contact us today for a personalized consultation and discover how the right press can enhance your efficiency, safety, and bottom line.

Get Your Free Expert Recommendation

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy