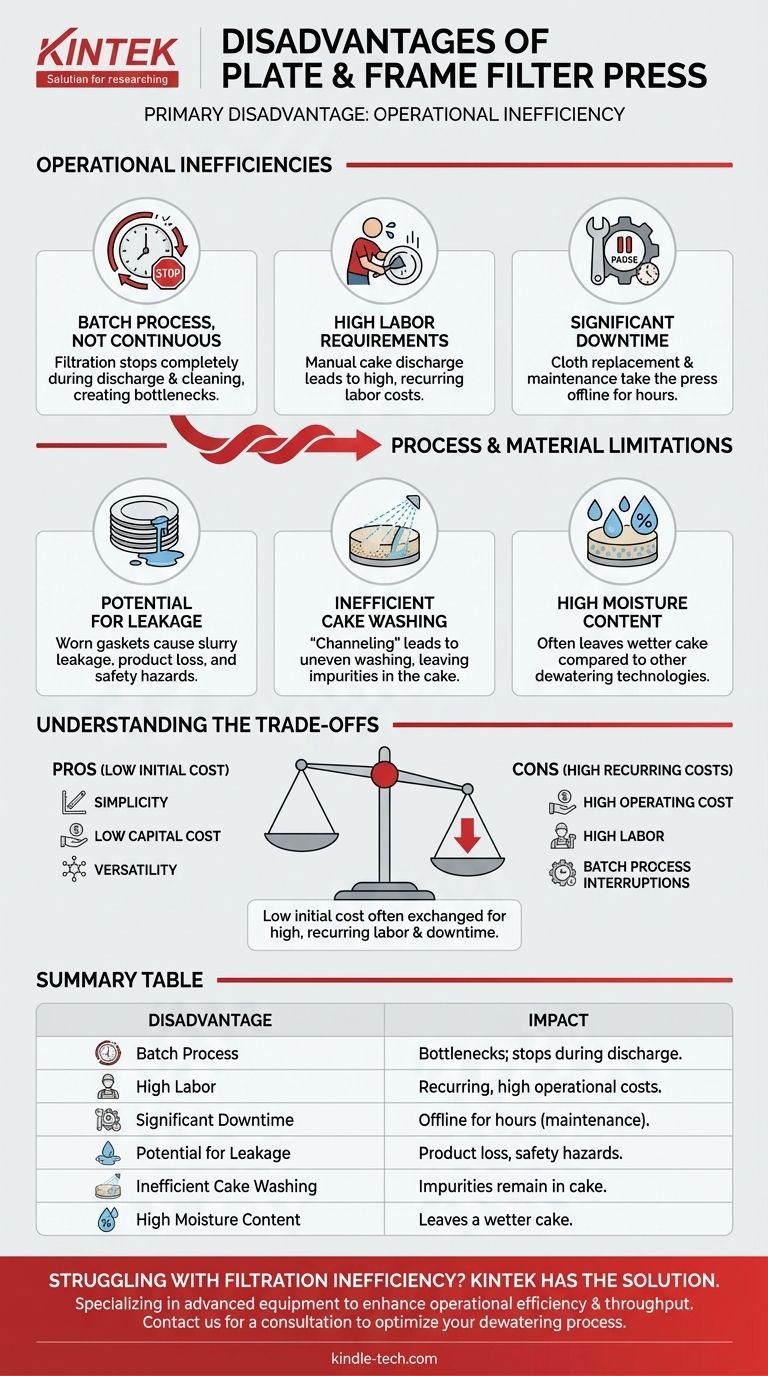

The primary disadvantage of a plate and frame filter press is its operational inefficiency, stemming from its nature as a labor-intensive, batch-processing system. This leads to significant downtime between filtration cycles and high ongoing operational costs, especially when compared to more automated, continuous filtration technologies.

While mechanically simple and effective for many applications, the plate and frame filter press exchanges low initial capital cost for high, recurring labor costs and process interruptions, making it a poor fit for large-scale or continuous operations.

The Operational Inefficiencies

The most significant drawbacks of a plate and frame press are not related to its filtration capability but to the way it operates. These inefficiencies directly impact throughput, labor budgets, and overall process uptime.

It's a Batch Process, Not Continuous

A filter press operates in distinct cycles: filling, pressing, opening, cake discharge, and closing. The process is inherently intermittent.

This means filtration stops completely during the discharge and cleaning cycle. This non-productive time can be substantial, creating a bottleneck in any process that requires a steady, continuous flow.

High Labor Requirements

Operating a filter press, especially a manual or semi-automatic one, is physically demanding and time-consuming.

Operators must manually open the press, separate the plates, and scrape the filter cake from each cloth. This direct involvement translates to high and recurring labor costs that persist for the life of the machine.

Significant Downtime for Maintenance

The filter cloths are the heart of the press, but they wear out and require regular replacement.

Changing a full set of cloths is a major maintenance event that can take the press offline for hours or even an entire shift. Similarly, the gaskets that seal the plates can wear, requiring further downtime for replacement.

Process and Material Limitations

Beyond the operational cycle, the design itself imposes certain limitations on performance and the types of materials it can handle effectively.

Potential for Leakage

The press relies on hydraulic pressure to clamp the stack of plates together, creating a seal with gaskets.

Over time, or with improper alignment, these gaskets can wear and fail, leading to slurry leakage. This not only results in product loss but also creates significant housekeeping and potential safety hazards.

Inefficient Cake Washing

While possible, washing the filter cake to remove residual soluble impurities is often inefficient in a plate and frame press.

The wash liquid may not distribute evenly, a phenomenon known as "channeling," which leaves parts of the cake unwashed. This makes it unsuitable for applications requiring high-purity solids.

High Moisture Content in Cake

Compared to other dewatering technologies, a standard plate and frame press often leaves a relatively high moisture content in the discharged cake. While membrane plates can improve this, achieving very dry solids may require a different technology or an additional downstream drying step.

Understanding the Trade-offs

The disadvantages of a plate and frame press must be weighed against its clear advantages, which explain its continued widespread use. Its limitations are often an acceptable trade-off for its benefits in the right context.

Simplicity vs. Automation

The core trade-off is simplicity for automation. The press has few moving parts, is mechanically robust, and is easy to understand and repair. This makes it reliable but dependent on manual labor.

Low Capital Cost vs. High Operating Cost

The initial purchase price of a plate and frame press is often significantly lower than more complex, automated systems like a belt filter or rotary drum filter. Businesses often accept the higher long-term labor costs in exchange for this lower barrier to entry.

Versatility vs. Specialization

A filter press is a general-purpose workhorse. It can handle a wide variety of slurries, from fine chemicals to industrial waste, making it a flexible asset. More specialized filters may be more efficient for a single process but lack this adaptability.

Making the Right Choice for Your Process

Selecting the correct dewatering technology requires a clear understanding of your primary operational goal.

- If your primary focus is low capital cost and process flexibility: The plate and frame press is a strong contender, as long as your production volume can tolerate a batch process and you can absorb the ongoing labor costs.

- If your primary focus is high throughput and automation: You must look toward continuous systems like belt filters, which eliminate the batch cycle downtime and dramatically reduce labor requirements.

- If your primary focus is achieving the purest solids or the driest possible cake: A technology with more efficient cake washing and dewatering capabilities may be a better investment.

By understanding these core limitations, you can select a filtration technology that aligns with your operational reality, not just your initial budget.

Summary Table:

| Disadvantage | Impact |

|---|---|

| Batch Process | Creates bottlenecks; filtration stops during discharge/cleaning. |

| High Labor Requirements | Manual cake discharge leads to recurring, high operational costs. |

| Significant Downtime | Cloth replacement and maintenance can take the press offline for hours. |

| Potential for Leakage | Worn gaskets can cause slurry leakage, leading to product loss. |

| Inefficient Cake Washing | Poor wash liquid distribution can leave impurities in the cake. |

| High Moisture Content | Often leaves a wetter cake compared to other dewatering technologies. |

Struggling with Filtration Inefficiency? KINTEK Has the Solution.

Is your process suffering from the high labor costs and downtime of a plate and frame filter press? KINTEK specializes in advanced laboratory and processing equipment designed to enhance your operational efficiency and throughput.

We understand that the right technology is key to a profitable operation. Let our experts help you evaluate your specific needs and identify a filtration solution that minimizes downtime and maximizes your ROI.

Contact us today to discuss how we can optimize your dewatering process.

Get a Free Consultation & Explore Your Options

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation