At its core, Hot Isostatic Pressing (HIP) is a manufacturing process that subjects a component to both elevated temperature and high, uniform gas pressure. The purpose is not to change the part's shape, but to improve its internal structure by eliminating porosity, consolidating powders into a solid mass, or creating a metallurgical bond between different materials.

The central purpose of Hot Isostatic Pressing is to achieve a perfectly dense material structure. By applying uniform pressure from all directions at high temperatures, the process closes and welds shut internal voids that compromise the mechanical performance and reliability of critical components.

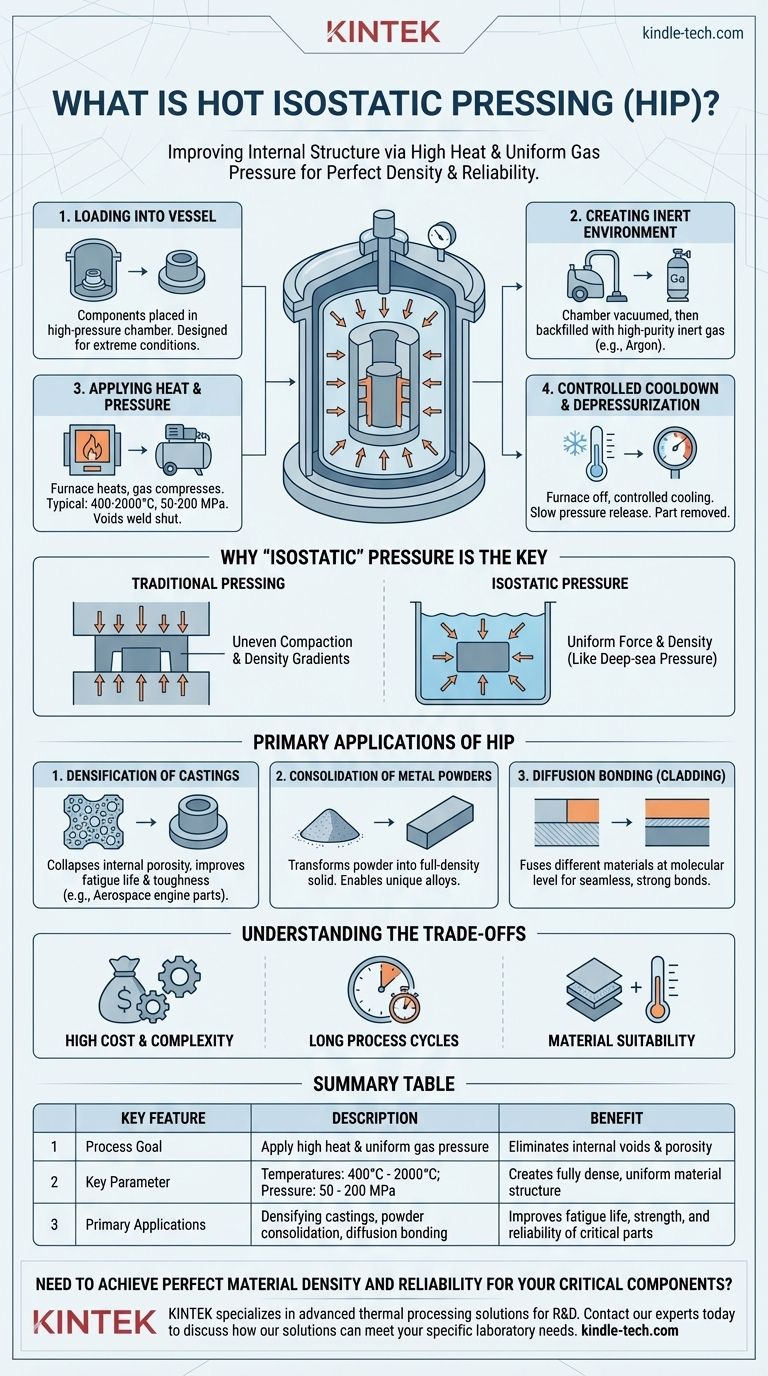

How the HIP Process Works

The HIP process takes place inside a specialized high-pressure vessel and is managed by precise computer controls. The cycle is tailored to the specific material and desired outcome.

Step 1: Loading into the Vessel

Components are loaded into a cylindrical chamber, which is the core of the HIP unit. This vessel is designed to withstand extreme internal pressures and temperatures.

Step 2: Creating an Inert Environment

The chamber is sealed and vacuumed to remove the atmosphere. It is then backfilled with a high-purity inert gas, most commonly argon, which will act as the pressure-transmitting medium.

Step 3: Applying Heat and Pressure

An internal heating furnace raises the temperature inside the vessel, while gas compressors simultaneously increase the pressure. This combination of heat and pressure is held for a specific duration.

Typical parameters can range from 400°C to 2000°C and pressures from 50 to 200 MPa. The heat softens the material, allowing the high gas pressure to collapse and weld shut any internal voids.

Step 4: Controlled Cooldown and Depressurization

After the hold time, the furnace is turned off and the component cools in a controlled manner. The gas pressure is slowly released, and once the part is at a safe temperature, it can be removed from the vessel.

Why "Isostatic" Pressure Is the Key

The defining feature of this process is the nature of the pressure itself. Understanding this is crucial to grasping its benefits.

The Principle of Uniform Force

"Isostatic" means that the pressure is applied equally and simultaneously from all directions. Imagine an object submerged deep in the ocean; the water pressure acts on its entire surface uniformly. The argon gas in a HIP vessel behaves the same way.

The Benefit of Uniform Density

In traditional pressing, where a part is squeezed between two dies, friction with the die walls can lead to uneven compaction and density gradients. Isostatic pressure eliminates this issue, ensuring the resulting component has a perfectly uniform density throughout its structure. This uniformity translates directly to more predictable and reliable mechanical properties.

Primary Applications of Hot Isostatic Pressing

HIP is not a one-size-fits-all solution but a targeted process for three primary goals.

1. Densification of Castings

Metal castings often suffer from internal porosity, or tiny voids, caused by shrinkage during solidification. HIP collapses these voids, creating a fully dense part with dramatically improved fatigue life and fracture toughness. This is critical for high-performance cast parts like aerospace engine components.

2. Consolidation of Metal Powders

HIP can transform metal or ceramic powders into a fully dense, solid component. The powder is sealed in a canister, which is then subjected to the HIP process. This method allows for the creation of parts from unique alloys that are difficult or impossible to produce via conventional melting and casting.

3. Diffusion Bonding (Cladding)

The process can be used to fuse two or more different materials together at a molecular level without melting. Under heat and pressure, atoms from each material diffuse across the boundary, creating a metallurgical bond that is as strong as the parent materials themselves.

Understanding the Trade-offs

While powerful, HIP is a specialized process with important considerations.

High Cost and Complexity

HIP equipment is a significant capital investment, and the operating costs related to energy, inert gas, and cycle time are substantial. The process is reserved for components where performance and reliability are paramount.

Long Process Cycles

A full HIP cycle—including heating, holding at temperature and pressure, and cooling—can take many hours. This makes it unsuitable for high-volume, low-cost manufacturing.

Material Suitability

The material being processed must be able to withstand the high temperatures without degrading. The process parameters must be carefully calibrated for each specific alloy to achieve densification without negatively affecting the material's microstructure.

Making the Right Choice for Your Project

Your decision to use HIP should be driven by a clear engineering requirement.

- If your primary focus is reliability in a critical cast part: Use HIP to eliminate internal porosity and significantly increase the component's fatigue life and strength.

- If your primary focus is creating a part from a novel or non-weldable alloy: Use HIP to consolidate metal powders into a fully dense, near-net-shape component with a uniform microstructure.

- If your primary focus is joining dissimilar materials for extreme performance: Use HIP diffusion bonding to create a seamless, full-strength metallurgical bond that outperforms conventional joining methods.

Ultimately, Hot Isostatic Pressing is the definitive tool for achieving the highest possible material integrity when failure is not an option.

Summary Table:

| Key Feature | Description | Benefit |

|---|---|---|

| Process Goal | Apply high heat & uniform gas pressure | Eliminates internal voids & porosity |

| Key Parameter | Temperatures: 400°C - 2000°C; Pressure: 50 - 200 MPa | Creates fully dense, uniform material structure |

| Primary Applications | Densifying castings, powder consolidation, diffusion bonding | Improves fatigue life, strength, and reliability of critical parts |

Need to achieve perfect material density and reliability for your critical components?

KINTEK specializes in advanced thermal processing solutions, including lab-scale equipment for research and development. Whether you are developing new alloys, improving casting quality, or exploring diffusion bonding, our expertise and products can help you achieve superior material performance.

Contact our experts today to discuss how our solutions can meet your specific laboratory and R&D needs.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is HIP in material processing? Achieve Near-Perfect Density for Critical Components

- What are the components of a hot isostatic pressing system? A Guide to Core HIP Equipment

- What is the historical background of the Hot Isostatic Pressing (HIP) process? From Nuclear Roots to Industry Standard

- What is the principle of hot isostatic pressing? Achieve 100% Density and Superior Performance

- What is the HIP material process? Achieve Near-Perfect Density and Reliability