In infrared (IR) spectroscopy, the KBr method is a traditional and highly effective technique for analyzing solid samples. It involves intimately mixing a small amount of the sample with high-purity potassium bromide (KBr) powder, grinding the mixture finely, and then compressing it under high pressure to form a thin, transparent disc or "pellet." This pellet serves as a solid-state window through which the IR beam can pass, allowing for a clear transmission measurement.

The KBr pellet method's core purpose is to suspend a solid sample in an IR-transparent matrix, enabling the acquisition of a high-quality transmission spectrum. Its success, however, is critically dependent on meticulous sample preparation to eliminate moisture and light-scattering effects.

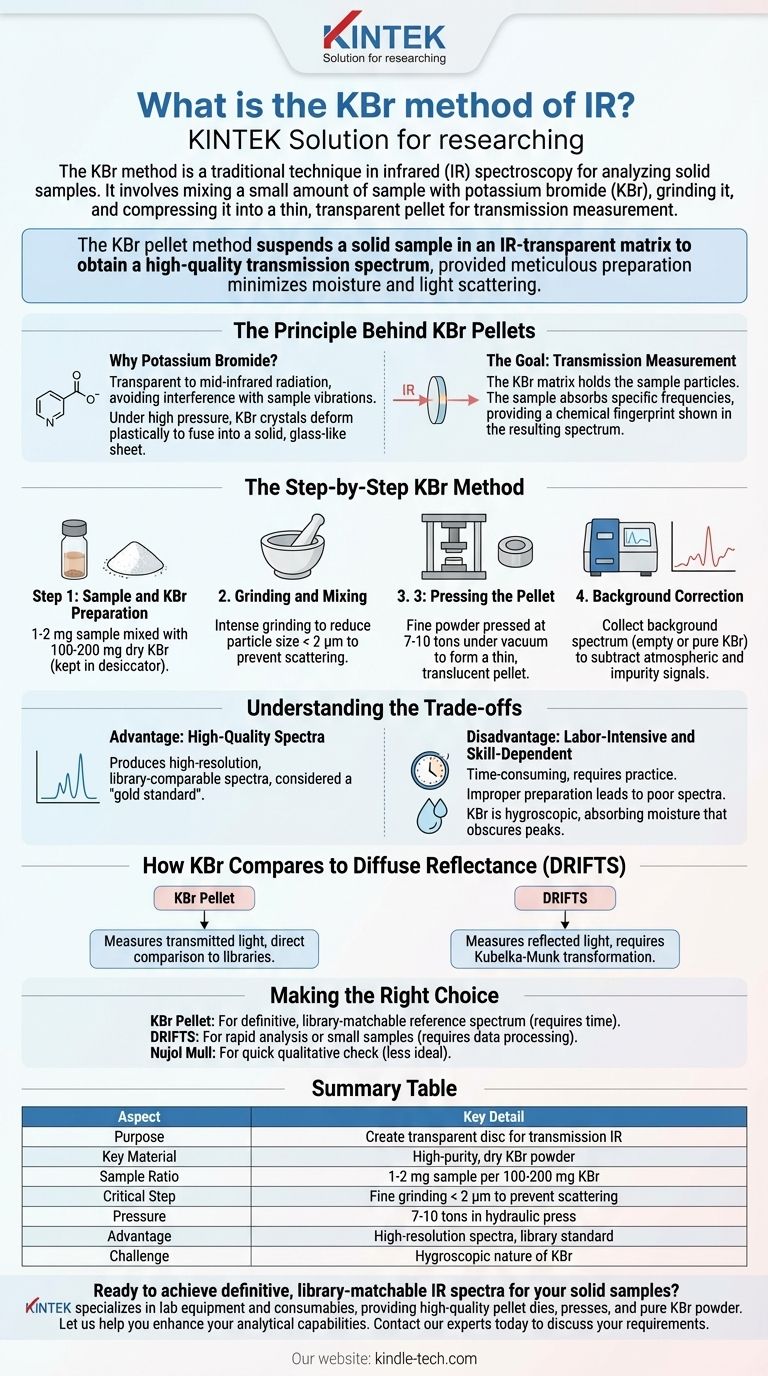

The Principle Behind KBr Pellets

Why Potassium Bromide?

Potassium bromide (KBr) is an alkali halide salt with two critical properties for IR spectroscopy. First, it is transparent to mid-infrared radiation, meaning it does not absorb light in the region where most organic and inorganic compounds have their characteristic vibrations.

Second, under high pressure, KBr crystals deform plastically. This allows the powder to fuse into a solid, glass-like sheet that locks the dispersed sample particles in place.

The Goal: Transmission Measurement

The ultimate goal is to measure the light that passes through the sample. The KBr matrix holds the finely ground sample particles in the path of the spectrometer's IR beam.

As the beam passes through, the sample molecules absorb energy at specific frequencies corresponding to their vibrational modes. The resulting spectrum shows these absorptions, providing a chemical "fingerprint" of the substance.

The Step-by-Step KBr Method

Sample and KBr Preparation

The process begins with a very small amount of sample, typically only 1-2 milligrams, mixed with about 100-200 milligrams of dry, spectroscopy-grade KBr powder. The KBr must be kept in a desiccator or drying oven to prevent moisture absorption.

Grinding and Mixing

This is the most critical step. The sample and KBr are ground together intensely, usually with an agate mortar and pestle, to reduce the sample's particle size.

The particles must be smaller than the wavelength of the IR light (less than ~2 µm) to prevent scattering, which can cause a sloping baseline and distorted peaks in the final spectrum.

Pressing the Pellet

The fine powder mixture is transferred to a pellet die. The die is placed under a vacuum to remove trapped air and moisture, which would otherwise interfere with the measurement.

A hydraulic press is then used to apply immense pressure (typically 7-10 tons) to the die, compressing the powder into a thin, translucent pellet.

Background Correction

Before analyzing the sample, a background spectrum is collected. This can be done with an empty sample holder or, ideally, with a pellet made of pure KBr.

This step allows the instrument's software to subtract any interfering signals from atmospheric water vapor, carbon dioxide, or minor impurities within the KBr itself.

Understanding the Trade-offs

Advantage: High-Quality Spectra

When performed correctly, the KBr method produces transmission spectra with high resolution and a flat baseline. These spectra are considered a "gold standard" and are directly comparable to vast commercial and academic spectral libraries.

Disadvantage: Labor-Intensive and Skill-Dependent

The process of grinding, mixing, and pressing is time-consuming and requires practice to master. An improperly made pellet can lead to poor-quality, uninterpretable spectra.

The Problem of Moisture

KBr is hygroscopic, meaning it readily absorbs water from the atmosphere. This is the most common source of error.

Absorbed water creates broad, distinct peaks in the IR spectrum (around 3400 cm⁻¹ and 1640 cm⁻¹) that can obscure or be mistaken for sample peaks, particularly O-H and N-H stretching bands.

How KBr Compares to Diffuse Reflectance

The diffuse reflectance (DRIFTS) method is a common alternative that is often faster, as it does not require pressing a pellet. It's also better for analyzing very small sample quantities.

However, DRIFTS measures reflected light, not transmitted light. The resulting spectrum must be mathematically converted using the Kubelka-Munk transformation to resemble a standard absorbance spectrum, adding a layer of data processing.

Making the Right Choice for Your Goal

Selecting the correct sample preparation technique is fundamental to good spectroscopic data.

- If your primary focus is obtaining a definitive, library-matchable reference spectrum: The KBr pellet method is the superior choice, provided you invest the time in meticulous preparation.

- If your primary focus is rapid analysis or you have a very small amount of sample: Consider the Diffuse Reflectance (DRIFTS) method for its speed and sensitivity, but be prepared to apply the necessary data transformations.

- If your primary focus is a quick, qualitative check with minimal equipment: A Nujol mull (suspending the sample in mineral oil) is a viable, though often less ideal, alternative.

Ultimately, understanding the principles and pitfalls of each technique empowers you to generate the most accurate and reliable data for your analytical needs.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Purpose | Create a transparent disc for transmission IR measurement of solids. |

| Key Material | High-purity, dry Potassium Bromide (KBr) powder. |

| Sample Ratio | 1-2 mg sample per 100-200 mg KBr. |

| Critical Step | Fine grinding to particle size < 2 µm to prevent light scattering. |

| Pressure for Pellet | 7-10 tons in a hydraulic press. |

| Primary Advantage | Produces high-resolution spectra comparable to library standards. |

| Main Challenge | Hygroscopic nature of KBr requires careful moisture control. |

Ready to achieve definitive, library-matchable IR spectra for your solid samples?

The KBr pellet method is a gold standard, but its success hinges on proper technique and reliable equipment. KINTEK specializes in lab equipment and consumables, serving laboratory needs with high-quality pellet dies, presses, and pure KBr powder to ensure your sample preparation is precise and moisture-free.

Let us help you enhance your analytical capabilities. Contact our experts today to discuss your IR spectroscopy requirements and discover the right solutions for your lab.

Visual Guide

Related Products

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- kbr pellet press 2t

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

People Also Ask

- How do laboratory hydraulic presses ensure reliability in PEC sealing? Unlock Stable & Leak-Proof Results

- What role does a laboratory hydraulic press play in testing conductivity? Enhancing Nanoparticle Powder Analysis

- What are five things you should consider when using a hydraulic press? Ensure Safe and Efficient Operation

- Why is a laboratory hydraulic press essential for Cu-Mo alloy production? Maximize Green Body Strength and Density

- What scientific principle governs the operation of a hydraulic press? Master Pascal’s Law for Force Multiplication

- What happens after the HPHT growth cycle is complete and what shapes can the resulting diamonds have? Expert Analysis

- How are laboratory hydraulic presses used in PFC manufacturing? Precision Bonding for Extreme Environments

- What are the different types of forging process in automotive industry? Choose the Right Method for Your Parts