There is no single machine used in a feed mill; rather, a feed mill is a complex, integrated system of specialized machinery working in sequence. The core machines responsible for the transformation are the grinder (typically a hammer mill), the mixer, and the pellet mill. These machines work together to convert raw agricultural commodities into a homogenous, nutritionally balanced, and easily digestible final product.

A feed mill should be understood not as a collection of individual machines, but as a continuous production line. Each piece of equipment performs a specific function—from grinding and mixing to pelleting and cooling—that is critical for creating a safe, uniform, and nutritionally complete animal feed.

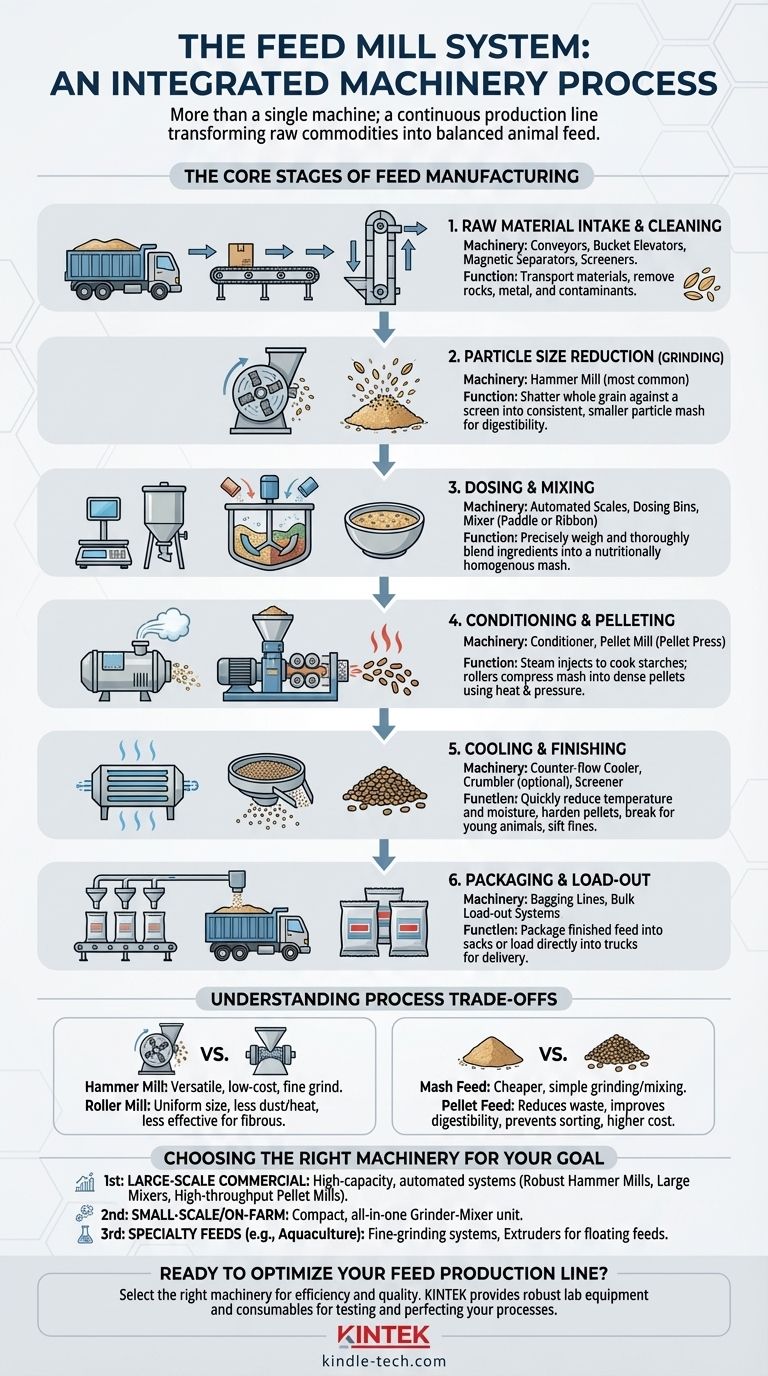

The Core Stages of Feed Manufacturing

The journey from raw grain to finished feed pellet follows a precise, multi-stage process. Each stage relies on specific machinery to prepare the material for the next step.

Stage 1: Raw Material Intake and Cleaning

Before any processing begins, raw ingredients like corn, soybeans, and wheat must be received and cleaned. This is the foundation of feed quality.

Machinery involved includes conveyors, bucket elevators, and magnetic separators or screeners. Their job is to transport materials and remove contaminants like rocks, metal, and dust.

Stage 2: Particle Size Reduction (Grinding)

Whole grains are too large for animals to digest efficiently and will not mix properly. They must be broken down into a consistent, smaller particle size.

The hammer mill is the most common machine for this task. It uses high-speed rotating hammers to shatter the grain against a metal screen, creating a coarse flour or "mash." The size of the holes in the screen determines the final particle size.

Stage 3: Dosing and Mixing

This is the most critical stage for nutritional accuracy. Each ingredient, from the main grains to micro-ingredients like vitamins and minerals, must be precisely weighed and thoroughly blended.

Ingredients are first weighed using automated scales and dosing bins. They are then transferred to a large mixer—most commonly a paddle mixer or ribbon mixer—which blends them into a completely homogenous mash, ensuring every bite of feed is nutritionally identical.

Stage 4: Conditioning and Pelleting

To improve digestibility and ease of handling, the mixed mash is often turned into pellets. This involves heat, moisture, and pressure.

First, the mash enters a conditioner, where steam is injected to cook the starches and increase moisture. This hot mash then flows into the pellet mill (or pellet press). Here, rollers force the mash through the holes of a thick steel die, compressing it into dense pellets.

Stage 5: Cooling and Finishing

The pellets exit the pellet mill extremely hot (160-180°F) and soft. They must be cooled and hardened to become stable for storage and transport.

A counter-flow cooler uses ambient air to quickly reduce the temperature and moisture content of the pellets. Afterward, some pellets may pass through a crumbler, which uses rollers to break them into smaller pieces for young animals. A screener then sifts out any fine powder, which is recycled back into the system.

Stage 6: Packaging and Load-Out

The finished product is now ready for delivery.

This final stage uses bagging lines for packaging feed into sacks or bulk load-out systems that fill trucks directly from storage bins for large-scale farm deliveries.

Understanding Key Process Trade-offs

The choice of machinery and process directly impacts feed quality, cost, and animal performance. Understanding these trade-offs is key to operating an effective mill.

Hammer Mill vs. Roller Mill

While the hammer mill is versatile and low-cost, a roller mill cracks grain between two rotating cylinders. A roller mill produces a more uniform particle size with less heat and dust but is less effective for fibrous ingredients. The choice depends on the specific animal and dietary goal.

Mash Feed vs. Pellet Feed

Producing a simple mash feed requires only grinding and mixing, making it significantly cheaper. However, pelleting reduces feed waste, prevents animals from selectively sorting ingredients, and improves digestibility through the cooking process. The added cost of pelleting is often recovered through better animal performance.

The Importance of Conditioning

Proper steam conditioning is crucial for producing durable, high-quality pellets. Insufficient conditioning results in brittle pellets and more "fines" (dust), while over-conditioning can waste energy and damage heat-sensitive nutrients. The balance is a constant operational challenge.

Making the Right Choice for Your Goal

The ideal machinery configuration depends entirely on your specific objective.

- If your primary focus is large-scale commercial production: Invest in high-capacity, automated systems with a focus on energy efficiency and durability, including robust hammer mills, large-volume mixers, and high-throughput pellet mills.

- If your primary focus is small-scale or on-farm use: A compact, all-in-one grinder-mixer unit is often the most cost-effective solution for producing simple mash feeds.

- If your primary focus is specialty feeds (e.g., aquaculture or pet food): You will need more advanced equipment like fine-grinding systems for smaller particles and extruders instead of pellet mills to create floating or slow-sinking feeds.

By understanding how these machines form an interconnected system, you can move beyond simply identifying parts and begin to grasp the entire process of modern feed manufacturing.

Summary Table:

| Core Feed Mill Machine | Primary Function |

|---|---|

| Hammer Mill / Grinder | Reduces raw grain particle size for digestibility. |

| Mixer (Paddle/Ribbon) | Blends ingredients into a nutritionally uniform mash. |

| Pellet Mill (Pellet Press) | Forms mash into dense, durable pellets using heat and pressure. |

| Conditioner | Injects steam to cook starches before pelleting. |

| Cooler | Cools and hardens hot pellets for storage and transport. |

Ready to Optimize Your Feed Production Line?

Whether you are planning a large-scale commercial mill or a compact on-farm operation, selecting the right machinery is critical for efficiency and feed quality. KINTEK specializes in providing robust and reliable lab equipment and consumables for the feed industry, helping you test and perfect your processes.

Contact our experts today to discuss how our solutions can help you achieve superior feed quality and operational efficiency.

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- kbr pellet press 2t

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- Why is a hydraulic press used for vacuum carbothermic magnesium reduction pellets? Protect Systems & Enhance Gas Flow

- How is a hydraulic press helpful for making KBr pellets? Achieve Superior FTIR Sample Preparation

- What is the use of manual hydraulic press? A Cost-Effective Tool for Lab Sample Preparation

- How do you prepare samples for infrared spectroscopy? Master Solid, Liquid & Gas Techniques

- Why is a laboratory hydraulic press essential for Ca3Co4O9 pelletizing? Optimize Pre-Sintering Mass Transport