At its core, an 1800-degree muffle furnace is a high-performance piece of laboratory or industrial equipment designed for heat-treating materials in a precisely controlled environment. Its defining feature is a sealed inner chamber, the "muffle," which isolates the material being heated from the electric heating elements. This separation ensures uniform heating without contamination, making it essential for advanced applications.

The true value of a muffle furnace is not just its ability to reach extreme temperatures, but its capacity to deliver clean, uniform, and indirect heat. This control is the critical factor for success in advanced material processing, research, and small-batch production.

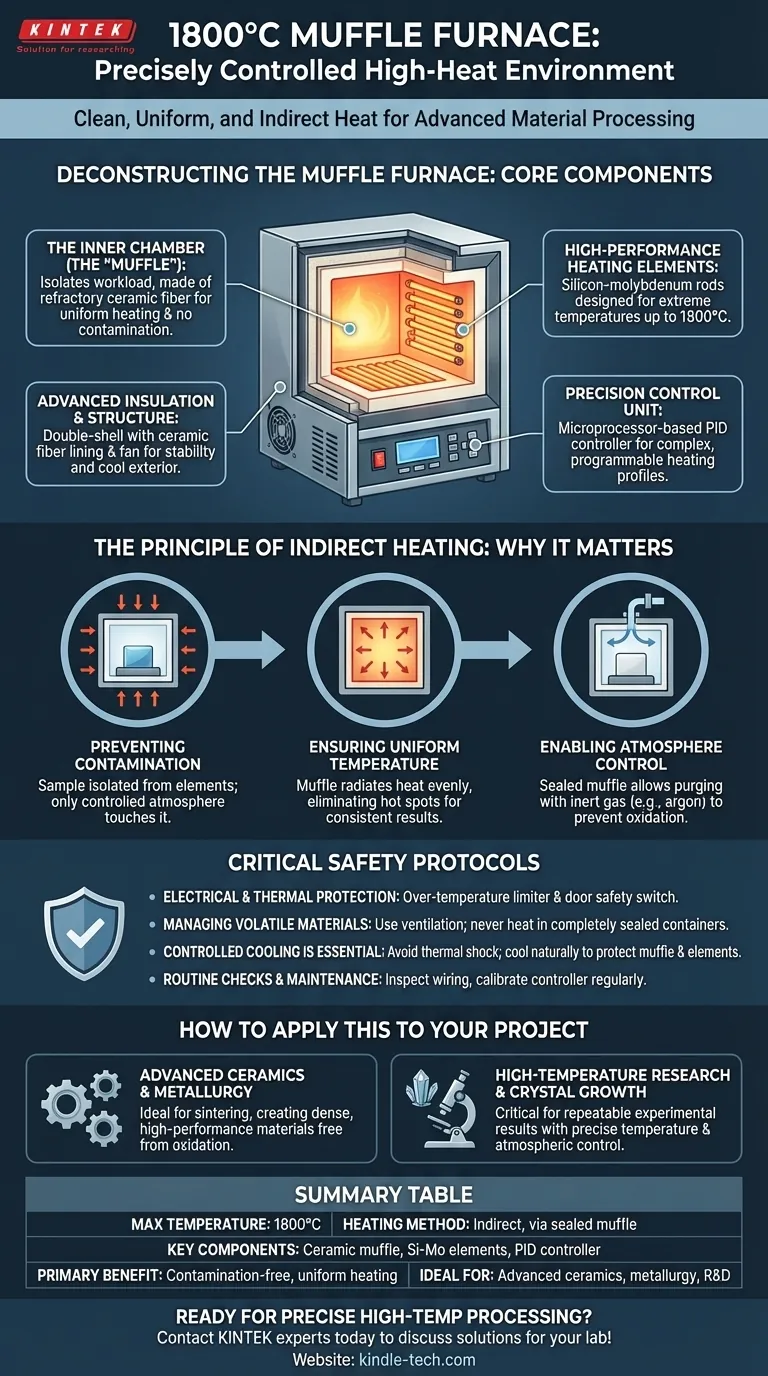

Deconstructing the Muffle Furnace: Core Components

A high-temperature muffle furnace is a system of specialized parts working in unison to create a stable and extreme thermal environment. Understanding these components reveals how it achieves its performance.

The Inner Chamber (The "Muffle")

The heart of the furnace is the muffle itself. This is a chamber made of highly refractory (heat-resistant) material, often a ceramic fiber.

Its purpose is to separate the workload from the heating elements. This prevents any particles from the elements from contaminating the sample and ensures the material is heated evenly by radiation, not direct contact.

High-Performance Heating Elements

Reaching 1800°C requires robust heating elements. While lower-temperature furnaces might use resistance wires, these high-temperature models rely on advanced materials.

Specialized components like silicon-molybdenum rods or silicon carbide rods are used for their ability to withstand and operate effectively at such extreme temperatures.

Advanced Insulation and Structure

Maintaining a stable 1800°C requires exceptional insulation to minimize heat loss and protect the operator.

Modern furnaces often use a double-shell structure with a fan to keep the outer casing cool. The internal chamber is lined with high-purity ceramic fiber, which provides excellent insulation and allows for relatively rapid heating and cooling cycles.

The Precision Control Unit

Temperature control is paramount. These furnaces are managed by a microprocessor-based PID (Proportional-Integral-Derivative) controller.

This unit allows the user to program complex heating profiles with multiple steps, ensuring precise temperature ramps and holds. It provides real-time temperature readings on an LED display and manages the power supplied to the elements.

The Principle of Indirect Heating: Why It Matters

The separation provided by the muffle is not an incidental design choice; it is fundamental to the furnace's function and enables processes that would otherwise be impossible.

Preventing Contamination

In many material science applications, even microscopic contamination can ruin a sample. Indirect heating ensures that the only thing touching the sample is the controlled atmosphere within the chamber.

Ensuring Uniform Temperature

The muffle absorbs heat from the elements and radiates it evenly onto the workload. This eliminates "hot spots" that can occur with direct heating, ensuring the entire sample experiences the same thermal profile, which is critical for consistent results.

Enabling Atmosphere Control

The sealed nature of the muffle allows for precise atmosphere control. Many units include a gas inlet, allowing users to purge the chamber with a non-flammable protective gas, like argon or nitrogen. This creates an inert environment to prevent oxidation at high temperatures.

Understanding Critical Safety Protocols

Operating a device at 1800°C presents significant hazards. Modern muffle furnaces are built with multiple safety layers, but operator diligence remains essential.

Electrical and Thermal Protection

These furnaces are equipped with an over-temperature limiter, which cuts power if the temperature exceeds a set safety threshold. A door safety switch also disconnects power to the heating elements when the door is opened, protecting the user from electric shock.

Managing Volatile Materials

Never heat volatile materials in a completely sealed container. The extreme heat can cause a dangerous buildup of pressure. Any process involving materials that may release gasses requires proper ventilation and container selection.

Controlled Cooling is Essential

Sudden temperature changes can cause thermal shock, cracking the ceramic muffle or damaging the heating elements. Always allow the furnace to cool down naturally. Abruptly opening the door at high temperatures is dangerous and destructive.

Routine Checks and Maintenance

Like any high-performance tool, a muffle furnace requires regular inspection. This includes checking the wiring for wear and periodically calibrating the temperature controller to ensure its accuracy.

How to Apply This to Your Project

The decision to use an 1800°C muffle furnace depends entirely on your material and process requirements.

- If your primary focus is advanced ceramic sintering or metallurgy: The uniform, high-temperature, and controlled atmosphere is ideal for creating dense, high-performance materials free from oxidation.

- If your primary focus is high-temperature research or crystal growth: The furnace's precise, programmable temperature control and atmospheric purity are critical for achieving repeatable experimental results.

- If your primary focus is general heat treatment like annealing or tempering steel: An 1800°C furnace is likely excessive; lower-temperature models are far more efficient and cost-effective for these common tasks.

Ultimately, a muffle furnace provides the clean, stable, and precise high-temperature environment necessary for the most demanding material science applications.

Summary Table:

| Feature | Description |

|---|---|

| Max Temperature | 1800°C |

| Heating Method | Indirect, via sealed muffle chamber |

| Key Components | Ceramic muffle, Si-Mo heating elements, PID controller |

| Primary Benefit | Contamination-free, uniform heating for sensitive materials |

| Ideal For | Advanced ceramics, metallurgy, high-temperature R&D |

Ready to achieve precise, contamination-free high-temperature processing? KINTEK specializes in laboratory equipment and consumables, providing reliable 1800°C muffle furnaces designed for advanced material science, research, and small-batch production. Our expertise ensures you get the right equipment for your specific needs, backed by exceptional support. Contact our experts today to discuss how our solutions can enhance your lab's capabilities!

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What are the precautions of muffle furnace? Essential Safety Protocols for Your Lab

- What is the principle working and use of muffle furnace? Achieve Precise, Contamination-Free Heating

- What is the purpose of a muffle furnace? Achieve High-Purity Heating for Your Lab

- What is the maximum temperature of a muffle furnace? Find the Right Heat for Your Application

- What does 'sintered' mean and why is it important to understand? Unlock Advanced Materials & Manufacturing