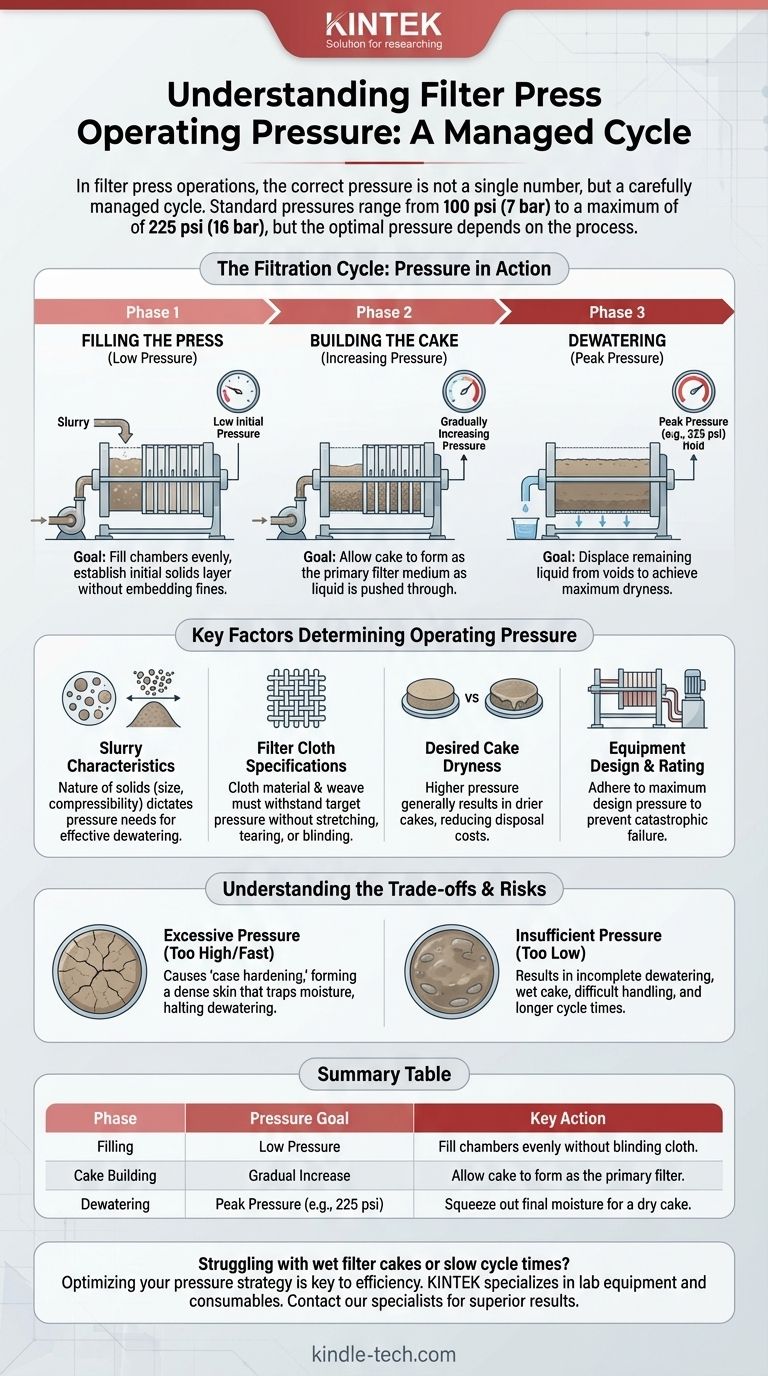

In filter press operations, the correct pressure is not a single number, but a carefully managed cycle. While standard operating pressures typically range from 100 psi (7 bar) to a maximum of 225 psi (16 bar), the optimal pressure depends entirely on the slurry being processed, the equipment's rating, and the desired final cake dryness.

The core principle is not simply to achieve maximum pressure, but to control the pressure curve throughout the entire filtration cycle. Applying pressure too quickly or incorrectly can blind the filter media and halt the dewatering process, regardless of the force applied.

The Role of Pressure in the Filtration Cycle

Effective filtration is a multi-stage process where pressure plays a different role in each phase. Understanding this cycle is critical to achieving a dry, solid cake efficiently.

Phase 1: Filling the Press (Low Pressure)

The cycle begins by using a feed pump, often a diaphragm pump, to fill the empty chambers of the filter press with slurry. This initial phase is done at a relatively low pressure.

The goal is to fill the volume completely and establish an initial, even layer of solids across the filter cloths without embedding fine particles deep into the fabric.

Phase 2: Building the Cake (Increasing Pressure)

As the chambers fill, solids begin to deposit on the filter cloths, forming a "filter cake." This cake itself becomes the primary filter medium, trapping subsequent particles.

During this phase, the pressure from the feed pump gradually increases as it becomes harder to push liquid through the accumulating solids.

Phase 3: Dewatering (Peak Pressure)

Once the chambers are packed with solids, the dewatering phase begins. The feed pump now works to displace the remaining liquid from the voids within the cake.

It is during this final stage that the system reaches its maximum designated operating pressure. This peak pressure is held for a set period until the filtrate flow slows to a trickle, indicating the cake is as dry as it can get under those conditions.

Key Factors Determining Operating Pressure

The ideal operating pressure is a calculated variable, not a fixed setting. It is dictated by the interplay of the material, the media, and the machine itself.

Slurry Characteristics

The nature of the solids in your slurry is the most important factor. Highly compressible or fine-particulate slurries often require higher pressures to squeeze out the maximum amount of water. Coarse, non-compressible solids dewater easily at lower pressures.

Filter Cloth Specifications

The filter cloth is the heart of the system. Its material and weave must be rated to withstand the target operating pressure without stretching, tearing, or "blinding"—where particles become irreversibly lodged in the fabric pores.

Desired Cake Dryness

There is a direct relationship between pressure and final cake moisture content. If the goal is to produce the driest possible cake to reduce disposal costs, a higher operating pressure is generally required.

Equipment Design and Rating

Every filter press has a maximum design pressure for its frame, plates, and hydraulic closing system. Exceeding this rating is dangerous and can cause catastrophic equipment failure.

Understanding the Trade-offs and Risks

Simply applying the maximum possible pressure is often counterproductive and can lead to significant operational problems.

The Risk of Excessive Pressure

Applying pressure too high or too quickly can create a dense, impermeable skin on the surface of the filter cake. This effect, known as "case hardening," prevents liquid from the cake's interior from escaping, trapping moisture and halting the dewatering process.

The Problem with Insufficient Pressure

Operating at a pressure that is too low for the application will result in an incomplete dewatering cycle. The consequences are a wet, "soupy" cake that is difficult to handle and longer cycle times, which reduces overall plant throughput.

Pressure Drop vs. Operating Pressure

Operating pressure is the force applied by the feed pump to the slurry. Pressure drop is the difference in pressure between the slurry inlet and the filtrate outlet. A high pressure drop can be a useful diagnostic tool, often indicating that the filter cake is fully formed or that the cloths are beginning to blind.

Determining the Right Pressure for Your Application

Optimizing your filter press requires matching the pressure strategy to your operational goal.

- If your primary focus is maximum cake dryness: Select a press and cloths rated for high pressure (e.g., 225 psi / 16 bar) and ensure a gradual pressure ramp-up to avoid blinding the media.

- If you are processing fragile or fine particles: Begin with lower feed pressures and allow for longer cycle times to build a permeable, effective filter cake without forcing particles into the cloth.

- If you need to optimize throughput and efficiency: The key is finding the "sweet spot" where a reasonably dry cake is achieved in the shortest possible time; this often means operating below the press's maximum pressure rating.

Ultimately, optimal filter press performance comes from intelligently managing the entire pressure curve, not just targeting a single maximum value.

Summary Table:

| Phase | Pressure Goal | Key Action |

|---|---|---|

| Filling | Low Pressure | Fill chambers evenly without blinding cloth. |

| Cake Building | Gradual Increase | Allow cake to form as the primary filter. |

| Dewatering | Peak Pressure (e.g., 225 psi) | Squeeze out final moisture for a dry cake. |

Struggling with wet filter cakes or slow cycle times? The right pressure strategy is key to efficiency. KINTEK specializes in lab equipment and consumables, serving precise laboratory filtration needs. Our experts can help you optimize your pressure cycle for maximum dryness and throughput. Contact our filtration specialists today to discuss your application and achieve superior results.

Visual Guide

Related Products

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What copper alloy for brazing? Choose Between Phos-Copper & Silver for Strong Joints

- What is the use of torrefaction? Upgrade Biomass into High-Energy 'Bio-Coal'

- Why is it necessary to dry or calcine catalysts? Ensure Reactor Safety and Peak Performance

- What are the parameters of magnetron sputtering process? Master Key Variables for Superior Thin Films

- What is the alternative source of energy biomass? Unlocking Renewable Power from Organic Materials

- Why is precise temperature control critical for ferritization products? Ensure material stability and performance.

- How does laboratory drying equipment affect the performance of hydrogel carriers? Optimize Drug Loading and Release

- What are some ways you can prevent injury when dealing with hot substances and objects? A Proactive Framework for Thermal Safety