In Chemical Vapor Deposition (CVD), there is no single pressure setting. The pressure is a critical process parameter that is intentionally controlled, typically ranging from atmospheric pressure down to a near-vacuum. Most modern applications use Low-Pressure CVD (LPCVD), operating between 1 and 1500 Pascals, to achieve high-quality, uniform films.

The core takeaway is that pressure in a CVD system is not a fixed value, but a fundamental control lever. The choice between low, atmospheric, or even high pressure directly dictates the trade-off between the speed of deposition and the ultimate quality, purity, and uniformity of the final material.

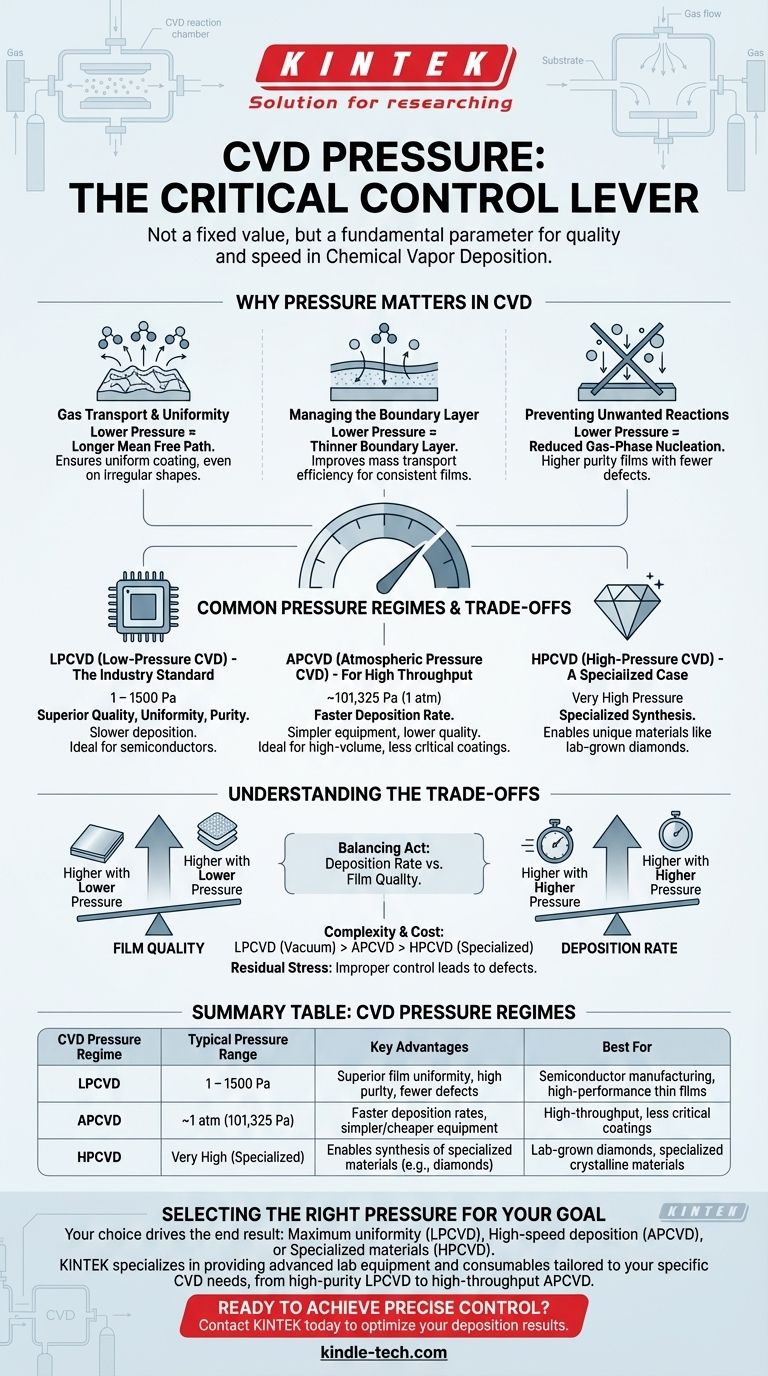

Why Pressure is a Critical Parameter in CVD

Pressure, along with temperature, is one of the two most important factors that determine the characteristics of the deposited film. It directly influences how precursor gases behave inside the reaction chamber.

Controlling Gas Transport and Uniformity

At lower pressures, gas molecules have a longer mean free path, meaning they travel further before colliding with each other. This allows the reactive gases to spread out more evenly throughout the chamber before landing on the substrate.

This behavior results in a significantly more uniform coating, even on complex, irregularly shaped surfaces. It is a key reason why CVD is not a "line-of-sight" process.

Managing the Boundary Layer

A thin, stagnant layer of gas, known as the boundary layer, naturally forms just above the substrate surface. Reactant gases must diffuse through this layer to reach the substrate and react.

Lowering the chamber pressure effectively thins this boundary layer. This improves the efficiency of mass transport to the surface, further enhancing the uniformity and consistency of the deposited film.

Preventing Unwanted Reactions

Many potential chemical reactions can occur in a CVD process. The goal is to have the reaction happen on the substrate surface, not in the gas phase above it.

Low pressure reduces the likelihood of gas-phase nucleation, where particles form in the gas and then fall onto the substrate. Preventing this ensures a higher purity film with fewer defects.

Common Pressure Regimes in CVD

The term "CVD" actually covers several techniques defined by their operating pressure.

Low-Pressure CVD (LPCVD): The Industry Standard

Operating in a partial vacuum (1–1500 Pa), LPCVD is the most common method for producing high-performance thin films in industries like semiconductor manufacturing.

The primary benefit is superior film quality, offering excellent uniformity and high purity. This is essential for creating the intricate, layered structures of modern electronics.

Atmospheric Pressure CVD (APCVD): For High Throughput

As the name implies, APCVD operates at standard atmospheric pressure. The equipment is generally simpler and does not require expensive vacuum systems.

The main advantage of APCVD is a much faster deposition rate. However, this speed comes at the cost of lower film quality and poorer uniformity compared to LPCVD.

High-Pressure CVD (HPCVD): A Specialized Case

For certain specialized applications, such as the synthesis of lab-grown diamonds, very high pressures are required.

In this process, high pressure and high temperature are used to force carbon atoms from precursor gases to deposit onto a diamond seed, replicating the conditions deep within the Earth. This is a capital-intensive and highly specialized technology.

Understanding the Trade-offs

Choosing a pressure regime is a matter of balancing competing priorities. There is no single "best" pressure, only the most appropriate one for a specific goal.

Deposition Rate vs. Film Quality

This is the central trade-off. Higher pressures lead to more molecular collisions and faster reactions, increasing deposition speed. Lower pressures slow the process down but produce a far superior, more uniform film.

Process Complexity and Cost

Operating at a vacuum (LPCVD) requires robust chambers and vacuum pumps, adding significant cost and complexity to the system. APCVD is simpler and cheaper to implement, while HPCVD represents the highest level of complexity and capital investment.

Residual Stress and Control

Improper control of deposition parameters, including pressure, can lead to residual stress within the deposited film. This internal stress can cause defects, delamination, or cracking, compromising the integrity of the final product.

Selecting the Right Pressure for Your Goal

Your choice of pressure should be driven by the end requirements of your application.

- If your primary focus is maximum film uniformity and purity: You must use LPCVD and accept the trade-off of a slower deposition rate.

- If your primary focus is high-speed deposition for less critical applications: APCVD is the logical choice, provided you can tolerate lower film quality.

- If your primary focus is creating specialized crystalline materials like synthetic diamonds: A dedicated HPCVD process is necessary to achieve the required material structure.

Ultimately, mastering pressure control is what transforms the CVD process from a simple coating technique into a precise manufacturing tool.

Summary Table:

| CVD Pressure Regime | Typical Pressure Range | Key Advantages | Best For |

|---|---|---|---|

| Low-Pressure CVD (LPCVD) | 1 – 1500 Pa | Superior film uniformity, high purity, fewer defects | Semiconductor manufacturing, high-performance thin films |

| Atmospheric Pressure CVD (APCVD) | ~101,325 Pa (1 atm) | Faster deposition rates, simpler/cheaper equipment | High-throughput, less critical coatings |

| High-Pressure CVD (HPCVD) | Very High (Specialized) | Enables synthesis of specialized materials (e.g., diamonds) | Lab-grown diamonds, specialized crystalline materials |

Ready to achieve precise control over your CVD process? The pressure regime is a critical lever for determining the quality, uniformity, and performance of your thin films. KINTEK specializes in providing advanced lab equipment and consumables tailored to your specific CVD needs, whether you require the high-purity capabilities of LPCVD or the high-throughput of APCVD. Let our experts help you select the right system to optimize your deposition results. Contact KINTEK today to discuss your laboratory requirements!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory CVD Boron Doped Diamond Materials

People Also Ask

- What is PECVD used for? Achieve Low-Temperature, High-Performance Thin Films

- What is plasma enhanced chemical vapour deposition process? Unlock Low-Temperature, High-Quality Thin Films

- What is plasma in CVD process? Lowering Deposition Temperatures for Heat-Sensitive Materials

- What is plasma enhanced chemical vapor deposition? Achieve Low-Temperature, High-Quality Thin Films

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition