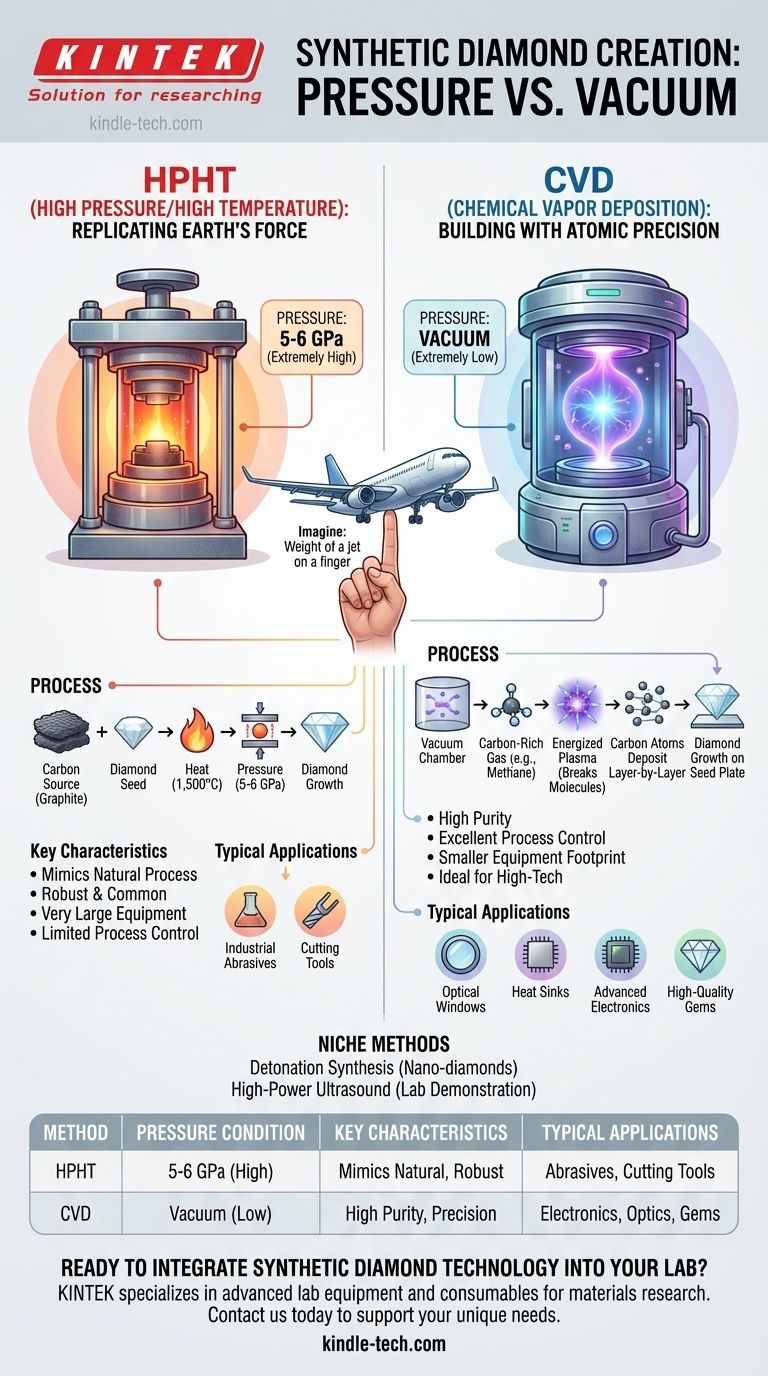

In short, creating a synthetic diamond using the High Pressure/High Temperature (HPHT) method requires immense pressure, typically around 5 to 6 Gigapascals (GPa). This is over 50,000 times the atmospheric pressure at sea level. However, this only tells half the story, as the other primary method, Chemical Vapor Deposition (CVD), operates under the exact opposite condition: a vacuum.

The core principle to understand is that creating a diamond is not about a single pressure value. It's about choosing one of two fundamentally different manufacturing philosophies: either replicating the brute force of the Earth (high pressure) or building the diamond atom-by-atom in a controlled vacuum (low pressure).

The Two Paths to Creating a Diamond

The method used to grow a diamond dictates the required conditions. The two dominant industrial processes, HPHT and CVD, approach the problem from opposite ends of the pressure spectrum.

HPHT: Replicating the Earth's Force

The High Pressure/High Temperature (HPHT) method is the original technique for diamond synthesis, designed to mimic the natural process deep within the Earth's mantle.

A small diamond seed is placed in a chamber with a carbon source, like graphite.

The chamber is then subjected to enormous pressures of 5-6 GPa and heated to extreme temperatures, typically around 1,500°C (2,732°F), dissolving the carbon and recrystallizing it onto the seed as a diamond.

To visualize this pressure, imagine the entire weight of a large commercial jet balanced on the tip of your finger.

CVD: Building with Atomic Precision

The Chemical Vapor Deposition (CVD) method does not rely on pressure. Instead, it "grows" a diamond in a highly controlled, low-pressure environment.

This process takes place inside a vacuum chamber, the opposite of the high-pressure conditions of HPHT.

Carbon-rich gases, such as methane, are introduced into the chamber and energized. This breaks the gas molecules apart, allowing pure carbon atoms to rain down and deposit onto a diamond seed plate, layer by atomic layer.

Understanding the Trade-offs

Each method's reliance on either extreme pressure or a controlled vacuum creates distinct advantages and disadvantages.

Why Choose High Pressure (HPHT)?

The HPHT method is a well-established process that effectively mimics nature. It is a robust and common technique for producing industrial-grade diamonds used for abrasives and cutting tools.

However, the references note that it often requires very large equipment to generate the necessary force and can offer limited process control compared to modern alternatives.

Why Choose Low Pressure (CVD)?

The primary advantage of the CVD method is its excellent process control. By carefully managing the gases and conditions, manufacturers can create exceptionally pure and large diamonds.

This precision makes CVD ideal for high-tech applications like optical windows for lasers, heat sinks, and advanced electronics. The references also highlight its smaller equipment footprint.

Are There Other Methods?

While HPHT and CVD dominate industrial production, two other methods exist, though they are not used for commercial gemstone or high-tech applications.

Detonation and Ultrasound

Detonation synthesis uses the force of carbon-containing explosives to create nanometer-sized diamond grains.

A fourth method, treating graphite with high-power ultrasound, has been demonstrated in laboratories but has no current commercial application. Both of these are niche processes for producing tiny, industrial-grade particles.

Making the Right Choice for Your Goal

The required pressure—or lack thereof—is a direct result of the desired outcome and application.

- If your primary focus is established industrial production: The brute force of the HPHT method is a proven path for creating diamonds for abrasives and cutting tools.

- If your primary focus is high purity and advanced applications: The atomic precision of the CVD method, which operates in a vacuum, offers the control needed for electronics, optics, and high-quality gems.

Ultimately, mastering diamond synthesis has meant conquering two opposite physical extremes to create one of nature's most valued materials.

Summary Table:

| Method | Pressure Condition | Key Characteristics | Typical Applications |

|---|---|---|---|

| HPHT | 5-6 GPa (Extremely High) | Mimics natural process, robust production | Industrial abrasives, cutting tools |

| CVD | Vacuum (Extremely Low) | High purity, excellent process control | Electronics, optics, high-quality gems |

Ready to integrate synthetic diamond technology into your lab? KINTEK specializes in providing advanced lab equipment and consumables for materials research, including diamond synthesis applications. Whether you're exploring HPHT or CVD methods, our expertise ensures you have the right tools for precision and efficiency. Contact us today to discuss how we can support your laboratory's unique needs!

Visual Guide

Related Products

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What are heated hydraulic presses used for? Molding Composites, Vulcanizing Rubber, and More

- How much psi can a hydraulic press make? From 2,000 PSI to over 50,000 PSI Explained

- What technical conditions does a heated hydraulic press provide for PEO batteries? Optimize Solid-State Interfaces

- What does a hydraulic heat press do? Achieve Industrial-Scale, Consistent Pressure for High-Volume Production

- Why do you need to follow the safety procedure in using hydraulic tools? Prevent Catastrophic Failure and Injury