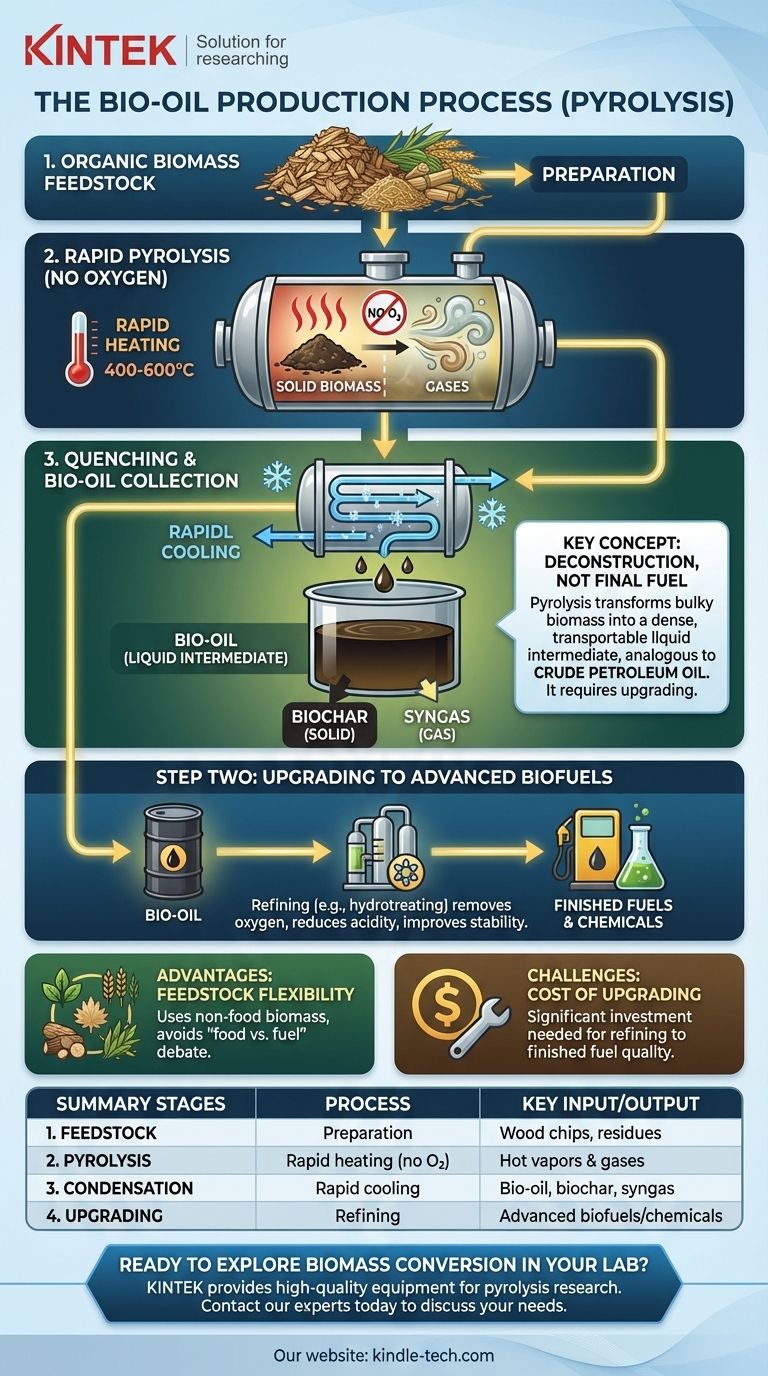

The primary method for producing bio-oil is a thermochemical process known as pyrolysis. This technique involves rapidly heating organic biomass, such as wood or agricultural waste, to high temperatures in an environment with very little oxygen. This prevents the material from burning and instead breaks it down into gases and vapors, which are then rapidly cooled and condensed into a dark, liquid product called bio-oil.

The production of bio-oil via pyrolysis is best understood not as creating a final fuel, but as a rapid "deconstruction" step that transforms solid, bulky biomass into a dense, liquid intermediate that is easier to store, transport, and upgrade into advanced biofuels.

The Core Mechanism: A Breakdown of Pyrolysis

Pyrolysis is a powerful and direct way to liquefy solid biomass. The process can be broken down into three fundamental stages, from the raw material to the final liquid product.

The Feedstock: Organic Biomass

The starting material for pyrolysis is biomass. This is a broad term for any organic matter, particularly non-food plant material like wood chips, corn stover, switchgrass, or other agricultural residues.

The Reaction: Rapid Heating Without Oxygen

The core of the process involves heating this biomass to high temperatures (typically 400-600°C) very quickly. Critically, this occurs in a reactor with an absence of oxygen.

The lack of oxygen is what distinguishes pyrolysis from combustion (burning). Instead of burning away, the complex polymers in the plant cell wall, like cellulose and lignin, are thermally decomposed into smaller, volatile molecules, forming hot gases and vapors.

The Transformation: Quenching Vapors into Liquid

These hot vapors are then rapidly cooled, or quenched. This rapid temperature drop forces the vapors to condense into a liquid.

This resulting liquid is pyrolysis oil, also known as bio-oil. The process also yields two other products: a solid carbon-rich material called biochar and non-condensable gases (syngas) which can be used to provide energy for the process itself.

Bio-Oil's Role in the Broader Biofuel Strategy

It is crucial to understand that producing raw bio-oil is rarely the end of the journey. It's an essential intermediate step in a larger, multi-stage process for creating advanced biofuels.

Step One: Deconstruction of Solid Mass

Pyrolysis serves as the deconstruction phase. It effectively breaks down the tough, rigid, and difficult-to-handle structure of solid biomass.

This transforms the material into a pumpable, energy-dense liquid, overcoming major logistical challenges associated with transporting bulky raw biomass.

A Necessary Intermediate, Not a Final Product

Raw bio-oil is not typically a "drop-in" replacement for conventional fuels like gasoline or diesel. It is often acidic, contains significant amounts of water and oxygen, and can be chemically unstable over time.

Think of it as analogous to crude petroleum oil. It is a valuable raw material, but it is not yet a finished, refined product ready for use in a standard engine.

Step Two: Upgrading to Finished Fuels

To become a usable fuel or high-value chemical, crude bio-oil must undergo upgrading. This is a refining stage where catalysts and processes like hydrotreating are used to remove oxygen, reduce acidity, and improve stability.

This upgrading step is what transforms the intermediate bio-oil into finished products like renewable hydrocarbon fuels or specialty biolubricants.

Understanding the Inherent Trade-offs

While powerful, the pyrolysis pathway has distinct advantages and challenges that define its role in the energy landscape.

The Key Advantage: Feedstock Flexibility

A major benefit of pyrolysis is its ability to process a wide variety of non-food biomass. This versatility allows for the use of agricultural and forestry waste, which avoids the "food vs. fuel" debate associated with some other biofuel processes.

The Key Challenge: The Cost of Upgrading

The primary challenge lies in the quality of the raw bio-oil. The fact that it requires significant, and often costly, upgrading to become a stable, finished fuel is a critical factor in its overall economic viability. The efficiency and cost of this second step are areas of intense research and development.

Making the Right Choice for Your Goal

To apply this knowledge effectively, consider your specific objective.

- If your primary focus is rapid biomass liquefaction: Pyrolysis is the most direct and efficient technology for converting solid, low-density biomass into a transportable liquid energy carrier.

- If your primary focus is producing a "drop-in" transportation fuel: View bio-oil production as the essential first step in a two-stage process that requires significant investment in downstream upgrading and refining technology.

- If you are comparing all biofuel technologies: Recognize that pyrolysis is a thermochemical pathway, distinct from biochemical pathways like fermentation (for ethanol) or transesterification (for biodiesel), each with its own feedstocks, processes, and end products.

Understanding this process reveals bio-oil as a crucial bridge, converting raw organic matter into a versatile platform for a new generation of sustainable fuels and chemicals.

Summary Table:

| Stage | Process | Key Input/Output |

|---|---|---|

| 1. Feedstock | Preparation of raw biomass | Wood chips, agricultural residues |

| 2. Pyrolysis | Rapid heating without oxygen (400-600°C) | Produces hot vapors and gases |

| 3. Condensation | Rapid cooling (quenching) of vapors | Yields liquid bio-oil, biochar, and syngas |

| 4. Upgrading | Refining bio-oil (e.g., hydrotreating) | Final advanced biofuels or chemicals |

Ready to explore biomass conversion in your lab?

KINTEK specializes in providing high-quality lab equipment for pyrolysis research and bio-oil analysis. Whether you're scaling up from bench-top reactors or need precise analytical tools, our solutions help you optimize your biofuel production process efficiently and reliably.

Contact our experts today to discuss your specific laboratory needs and discover how KINTEK can support your renewable energy innovations!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Graphite Vacuum Continuous Graphitization Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- Can a diamond tester be wrong? Yes, and here’s why you need more than one test

- What is the significance of a high-shear homogenizer in membrane preparation? Ensure Superior Casting Performance

- What are the factors that affect the filtration of the solution? Master the Key Variables for Optimal Performance

- What affects melting range? Understand the Critical Role of Purity and Structure

- What is a slow pyrolysis? A Guide to Maximizing Biochar Production from Biomass

- How plasma is generated in sputtering? The Engine Behind Thin-Film Deposition

- What can I use biochar for? A Guide to Soil Enhancement & Carbon Sequestration

- What are the types of sintering process? A Guide to Solid-State, Liquid Phase, and Advanced Methods