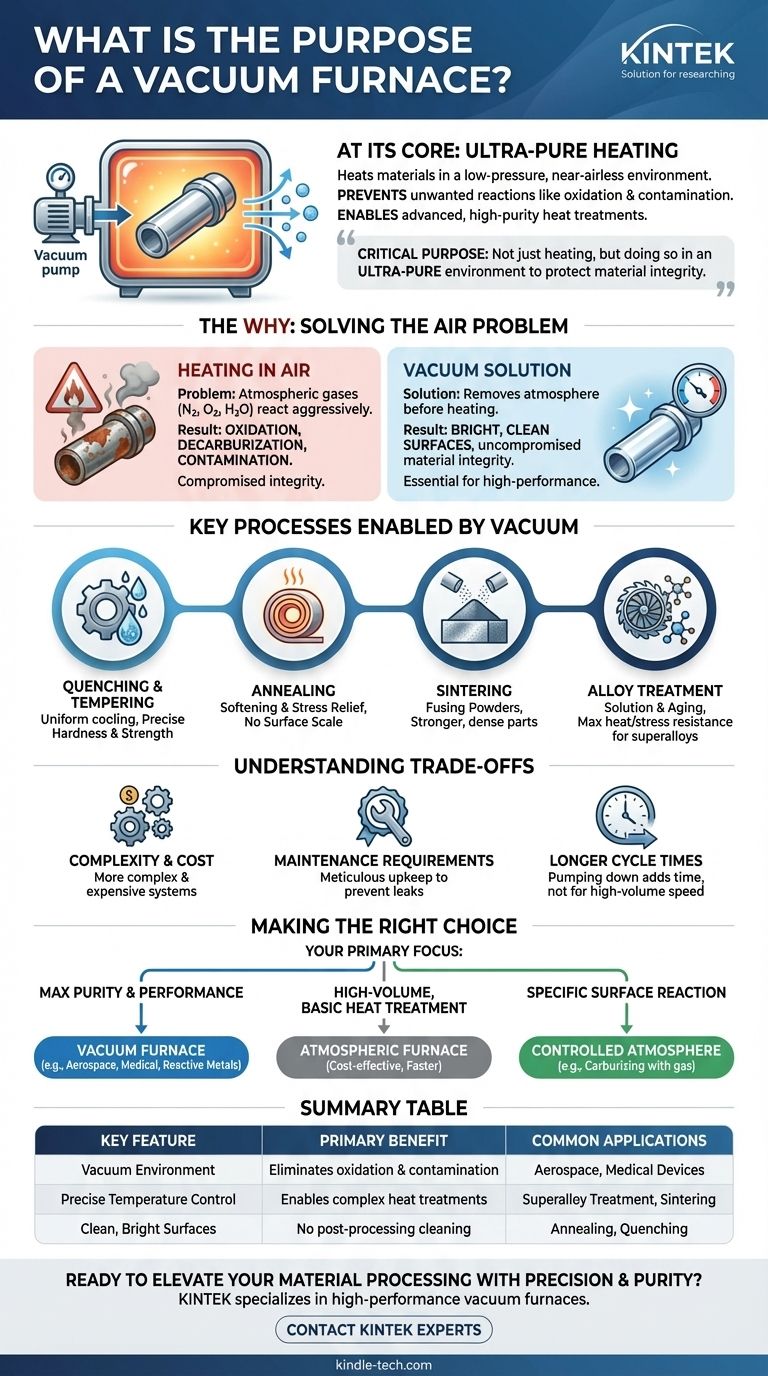

At its core, a vacuum furnace is a specialized piece of equipment designed to heat materials in a low-pressure, near-airless environment. This process fundamentally prevents unwanted chemical reactions, such as oxidation and contamination, that occur when materials are heated in the presence of air. It enables advanced heat treatments like quenching, annealing, and sintering with a level of purity and control that standard furnaces cannot achieve.

The critical purpose of a vacuum furnace is not just to heat materials, but to do so in an ultra-pure environment. By removing atmospheric gases, it protects the material's integrity, ensuring parts emerge with cleaner surfaces, superior mechanical properties, and no performance-degrading contamination.

Why a Vacuum is the Critical Ingredient

To understand the purpose of a vacuum furnace, you must first understand the problem it solves. Heating metals and other materials in the open air introduces a host of variables that can compromise their quality.

The Problem with Heating in Air

When materials are heated in a conventional furnace, they are exposed to the atmosphere, which is composed primarily of nitrogen, oxygen, and water vapor.

At high temperatures, these gases react aggressively with the material's surface. This leads to oxidation (rusting), decarburization (loss of carbon, which weakens steel), and general contamination, which can ruin the component's structural integrity and finish.

Creating an Ultra-Pure Environment

A vacuum furnace directly solves this problem by removing the atmosphere before the heating process begins.

It uses a sophisticated vacuum system—consisting of vacuum pumps, valves, and measuring devices—to evacuate the air from a sealed furnace chamber. This reduces the internal pressure far below standard atmospheric pressure, creating a clean, inert environment.

The Result: Uncompromised Material Integrity

By processing parts in a vacuum, manufacturers can ensure the final product is pristine. Materials emerge with bright, clean surfaces free of oxide layers.

This clean processing is essential for high-performance applications where even minor surface impurities can lead to component failure, particularly in industries like aerospace and medical devices.

Key Processes Enabled by a Vacuum

The controlled environment of a vacuum furnace is ideal for a range of sensitive thermal processes that demand precision and purity.

Hardening and Strengthening (Quenching & Tempering)

Vacuum quenching allows for rapid, uniform cooling of a part without the risk of surface contamination. This process is critical for achieving the precise hardness and strength required for high-stress components like gears and tooling.

Softening and Stress Relief (Annealing)

Annealing makes materials softer and easier to work with. Performing this process in a vacuum prevents the formation of surface scale, eliminating the need for subsequent cleaning operations and preserving the material's surface finish.

Fusing Powders (Sintering)

Vacuum sintering is a process where metal powders are heated to just below their melting point, causing them to bond and form a solid, dense part. The vacuum prevents trapped gases and impurities, resulting in stronger, more reliable components from powdered metallurgy.

Advanced Alloy Treatment (Solution & Aging)

High-performance materials, such as nickel-based superalloys used in jet engines and turbines, require complex heat treatments. A vacuum furnace provides the necessary contamination-free environment to ensure these alloys achieve their maximum resistance to heat and stress.

Understanding the Trade-offs

While incredibly capable, vacuum furnaces are specialized tools with specific considerations. They are not the default choice for every heating application.

Complexity and Cost

The sophisticated vacuum systems and controls make vacuum furnaces significantly more complex and expensive to purchase and operate than their atmospheric counterparts.

Maintenance Requirements

Maintaining the integrity of the vacuum is paramount. Seals, pumps, and gauges require regular, meticulous maintenance to prevent leaks, which would compromise the entire process and contaminate the furnace.

Longer Cycle Times

The process of pumping the chamber down to the required vacuum level adds significant time to each treatment cycle. This can make them less suitable for high-volume production where speed is the primary driver.

Making the Right Choice for Your Goal

Selecting the right furnace technology depends entirely on the material being processed and the desired outcome for the final component.

- If your primary focus is maximum material purity and performance: A vacuum furnace is non-negotiable for reactive metals, superalloys, or any application where an oxide-free surface is critical (e.g., aerospace, medical).

- If your primary focus is high-volume, basic heat treatment: A standard atmospheric furnace is often a more cost-effective and faster solution for materials where minor surface oxidation is acceptable or can be removed later.

- If your primary focus is inducing a specific surface reaction: A controlled atmosphere furnace, which replaces air with a specific process gas like nitrogen or argon, is the correct tool for processes like carburizing or nitriding.

Ultimately, choosing a vacuum furnace is a decision to prioritize material integrity and process control above all else.

Summary Table:

| Key Feature | Primary Benefit | Common Applications |

|---|---|---|

| Vacuum Environment | Eliminates oxidation & contamination | Aerospace, Medical Devices |

| Precise Temperature Control | Enables complex heat treatments | Superalloy Treatment, Sintering |

| Clean, Bright Surfaces | No post-processing cleaning required | Annealing, Quenching |

Ready to elevate your material processing with precision and purity?

KINTEK specializes in high-performance vacuum furnaces and lab equipment, designed to meet the stringent demands of industries like aerospace and medical device manufacturing. Our solutions ensure your materials achieve superior mechanical properties and flawless surface finishes.

Contact our experts today to discuss how a KINTEK vacuum furnace can optimize your heat treatment processes and deliver uncompromised quality.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Dental Porcelain Sintering Furnace

People Also Ask

- What are the advantages of vacuum hardening? Achieve Superior Precision and Cleanliness for Critical Components

- What are vacuum furnace parts? A Guide to the Core Systems for Precision Heat Treatment

- How does a vacuum heat treatment work? Achieve Superior Material Properties in a Pristine Environment

- What is a vacuum furnace? The Ultimate Guide to Contamination-Free Thermal Processing

- What is the vacuum heat treatment cycle? Achieve Superior Material Purity and Precision