At its core, an annealing oven is a specialized furnace that executes a precise heat treatment process. It works by heating a material like metal or glass to a specific temperature, holding it there, and then cooling it at a very slow, controlled rate. The purpose of this cycle is to fundamentally alter the material's internal structure, making it softer, more workable, and free from damaging internal stresses.

The real problem isn't that a material is hard; it's that manufacturing processes like casting, welding, or bending leave it filled with hidden internal stress. An annealing oven systematically removes this stress, transforming a brittle, unpredictable component into one that is stable, ductile, and reliable.

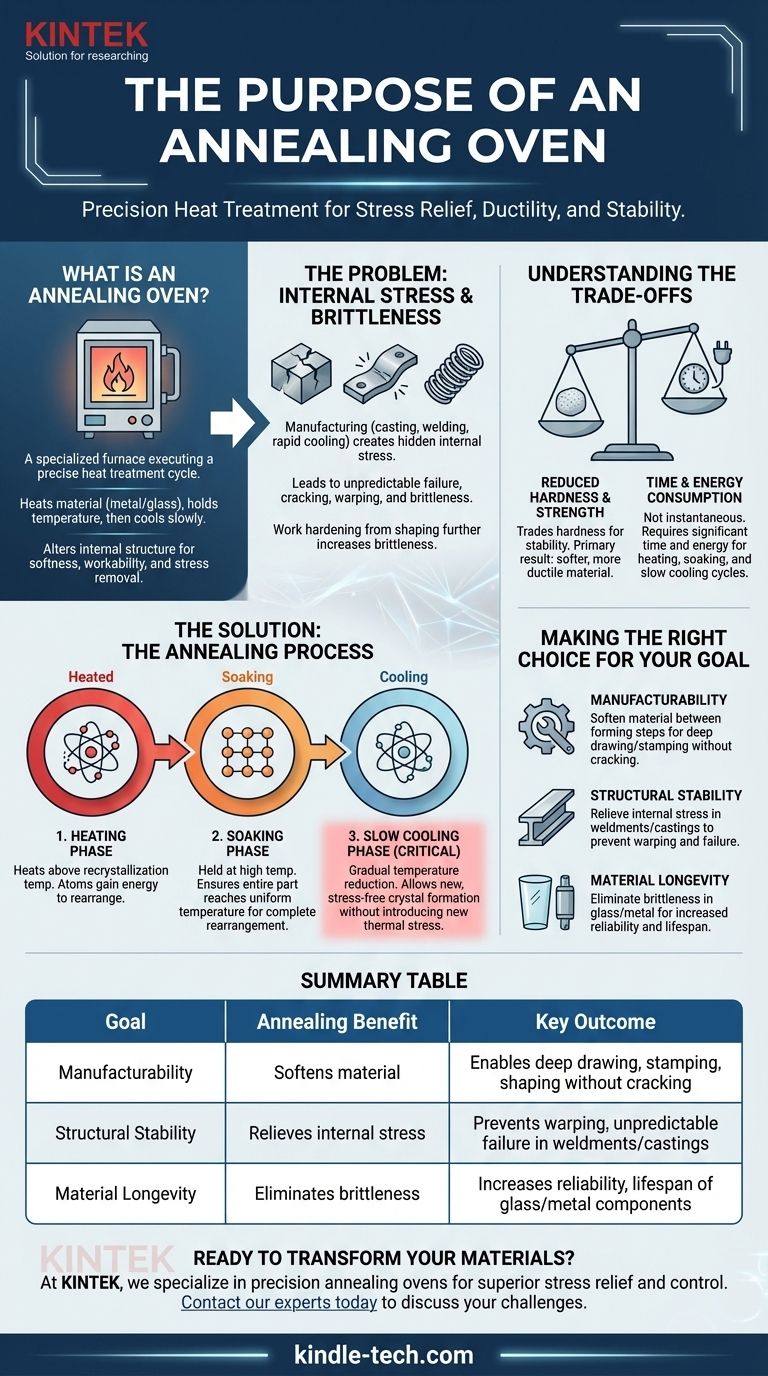

The Problem: Internal Stress and Brittleness

Nearly every manufacturing process introduces stress into a material. Annealing is the solution to the problems this stress creates.

Internal Stress: The Hidden Defect

When a metal part is cast, welded, or rapidly cooled, different sections cool at different rates. The exterior cools and shrinks first, while the core remains hot and expanded. This differential creates a microscopic tug-of-war within the material's crystal structure, locking in stress long after it has cooled.

The Consequence: Unpredictable Failure

A component with high internal stress is like a tightly wound spring. It may appear fine, but it is mechanically unstable and brittle. A small impact, a change in temperature, or minor operational strain can cause it to suddenly crack, warp, or shatter without warning.

Work Hardening

Similarly, when you bend or shape a metal, a process known as work hardening occurs. The material becomes stronger and harder, but it also becomes less ductile and more brittle. If you continue to work the metal, it will eventually fracture.

How an Annealing Oven Solves the Problem

The annealing process is a deliberate, three-stage solution designed to reset a material's internal structure at an atomic level.

The Heating Phase

The oven heats the material above its recrystallization temperature. At this point, the atoms gain enough energy to break their rigid, stressed bonds. This allows them to begin rearranging themselves into a more orderly and uniform crystal lattice.

The Soaking Phase

The material is held at this high temperature for a set period. This "soaking" ensures that the entire part—from the surface to the very core—reaches a uniform temperature and that the atomic rearrangement is complete.

The Slow Cooling Phase: The Critical Step

This is the most crucial stage. The oven reduces the temperature at a very slow, controlled rate. This gradual cooling allows the new, stress-free crystal structures to form without introducing new thermal stresses. Cooling the material too quickly would simply reintroduce the very problem annealing is meant to solve.

Understanding the Trade-offs

Annealing is a powerful process, but it involves making deliberate compromises in a material's properties.

Reduced Hardness and Strength

The primary result of annealing is a softer, more ductile material. This process intentionally reduces the material's tensile strength and hardness. You are trading hardness for stability and the ability to be shaped or machined without fracturing.

Time and Energy Consumption

Annealing is not an instantaneous process. The heating, soaking, and especially the slow cooling cycles can take many hours, or even days for very large components. This requires a significant input of energy, adding both time and cost to the manufacturing workflow.

Making the Right Choice for Your Goal

You should use an annealing process when the benefits of stress relief and increased ductility outweigh the reduction in hardness.

- If your primary focus is manufacturability: Use annealing to soften a material between forming steps, allowing for processes like deep drawing or stamping without cracking.

- If your primary focus is structural stability: Anneal finished parts like weldments or castings to remove internal stresses, ensuring they won't warp or fail unexpectedly.

- If your primary focus is material longevity: Anneal glass or metal to eliminate the microscopic stresses that make them brittle and prone to shattering, dramatically increasing their reliability.

Ultimately, annealing transforms a material from an unpredictable liability into a stable and reliable asset.

Summary Table:

| Goal | Annealing Benefit | Key Outcome |

|---|---|---|

| Manufacturability | Softens material | Enables deep drawing, stamping, and shaping without cracking |

| Structural Stability | Relieves internal stress | Prevents warping and unpredictable failure in weldments and castings |

| Material Longevity | Eliminates brittleness | Increases the reliability and lifespan of glass and metal components |

Ready to transform your materials from unpredictable liabilities into stable, reliable assets?

At KINTEK, we specialize in precision lab equipment, including advanced annealing ovens designed for superior stress relief and process control. Our solutions help you achieve consistent material properties, prevent costly failures, and enhance your manufacturing workflow.

Contact our experts today to discuss your specific material challenges and discover the right annealing solution for your laboratory.

Visual Guide

Related Products

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Dental Porcelain Sintering Furnace

People Also Ask

- How does a muffle oven work? Achieve Pure, Contamination-Free Heating for Your Lab

- What is the structure of a muffle furnace? A Guide to Its Core Components and Design

- Is firing the same as sintering? A Guide to Mastering Thermal Processing

- What is an oven furnace? Achieve Precise, Uniform Heat for Industrial & Lab Applications

- What specific role does a muffle furnace play in the final synthesis stage of Na3SbS4? Enhancing Ionic Conductivity

- How is a high-temperature muffle furnace utilized when testing fire resistance of geopolymers? Ensure Material Safety

- What are the primary functions of a laboratory oven in sol-gel nanocomposites? Ensure Structural Integrity & Precision

- How does a high-temperature furnace facilitate the synthesis of Zr3(Al1-xSix)C2 MAX phases? Achieve Phase Purity