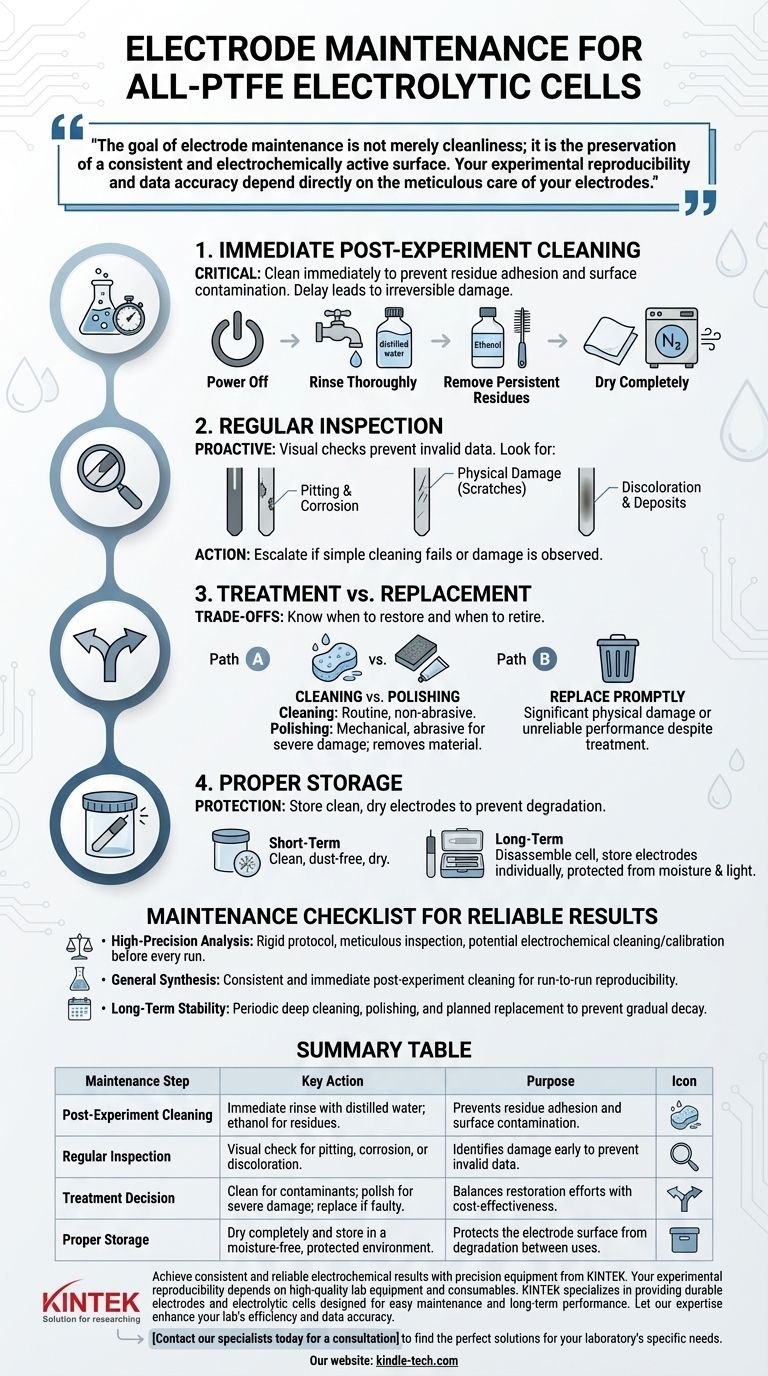

To properly maintain electrodes in an all-PTFE electrolytic cell, you must adopt a strict regimen of immediate post-experiment cleaning, regular visual inspection for wear and contamination, and correct storage. The core steps involve rinsing with distilled or deionized water, using solvents like ethanol for stubborn residues, and ensuring the electrodes are completely dry before being stored in a moisture-free, protected environment.

The goal of electrode maintenance is not merely cleanliness; it is the preservation of a consistent and electrochemically active surface. Your experimental reproducibility and data accuracy depend directly on the meticulous care of your electrodes.

The First Principle: Immediate Post-Experiment Cleaning

Cleaning electrodes and the reaction vessel immediately after use is the single most important step in maintenance. Waiting allows residues to dry, adhere, and potentially react with the electrode surface, causing irreversible contamination or damage.

Why Timing is Critical

Residues left on an electrode can become electrochemically "baked on" or can passively adsorb, altering the surface's properties for the next experiment. This leads to inconsistent results, such as shifts in potential or changes in current density, that are difficult to diagnose.

Step-by-Step Cleaning Protocol

First, ensure the power supply is off before handling any components. Rinse the electrodes thoroughly with distilled or deionized water to remove the bulk of the electrolyte and reaction products.

For more persistent residues, a rinse with a solvent like ethanol is often effective. If contamination remains, a mild acid or base treatment can be used, but this should be done with extreme care and knowledge of your electrode material's chemical compatibility.

Finally, dry the electrodes completely. This can be done by gently patting with a lint-free wipe, followed by air drying or using a stream of dry nitrogen.

The Core of Longevity: Regular Inspection

Proactive inspection prevents the use of a compromised electrode, saving you from generating invalid data. A quick visual check should be part of your pre-experiment and post-cleaning routine.

What to Look For

Examine the electrode surface for any signs of pitting, corrosion, or physical damage like scratches. Look for discoloration or stubborn deposits that could indicate contamination or oxide layer formation.

When to Escalate Action

If simple cleaning does not restore the electrode's appearance or if you observe physical damage, it is time to consider more intensive treatment or replacement. Using a damaged electrode knowingly will compromise your results.

Understanding the Trade-offs: When to Treat or Replace

Knowing when an electrode is salvageable versus when it needs to be retired is a critical skill that prevents wasted time and flawed experiments.

Cleaning vs. Polishing

Routine cleaning is a non-abrasive process designed to remove surface-level contaminants. Polishing, on the other hand, is a mechanical and abrasive process used to restore a damaged or heavily passivated surface. Polishing should be reserved for cases of severe contamination or damage, as it removes a small amount of the electrode material.

The Decision to Replace

An electrode should be replaced promptly if it shows significant physical damage, such as deep scratches or cracks. It should also be replaced if its performance becomes unreliable (e.g., poor calibration, drifting potential) even after thorough cleaning and polishing. Continuing to use a faulty electrode is a false economy.

Proper Storage: Protecting Your Investment

Correct storage protects the cleaned electrode surface from environmental contamination and physical damage between experiments.

Short-Term and Long-Term Strategies

For short-term storage, keeping the dried electrodes in a clean, dust-free, and dry container is sufficient.

For long-term storage, it is best to disassemble the cell completely. Store the electrodes individually in a protected case, away from moisture and light, to prevent slow degradation and accidental damage.

A Maintenance Checklist for Reliable Results

Your maintenance strategy should align with your experimental goals. Use these guidelines to tailor your approach.

- If your primary focus is high-precision quantitative analysis: Your protocol must be rigid, with meticulous inspection and potential electrochemical cleaning or calibration before every critical run.

- If your primary focus is general synthesis or material screening: A consistent and immediate post-experiment cleaning protocol is your highest priority to ensure run-to-run reproducibility.

- If your primary focus is long-term operational stability: Implement a schedule for periodic deep cleaning, polishing, and planned replacement of electrodes to prevent gradual performance decay.

Ultimately, treating your electrodes as precision instruments is fundamental to achieving trustworthy electrochemical data.

Summary Table:

| Maintenance Step | Key Action | Purpose |

|---|---|---|

| Post-Experiment Cleaning | Immediate rinse with distilled water; use ethanol for residues. | Prevents residue adhesion and surface contamination. |

| Regular Inspection | Visual check for pitting, corrosion, or discoloration. | Identifies damage early to prevent invalid data. |

| Treatment Decision | Clean for contaminants; polish for severe damage; replace if faulty. | Balances restoration efforts with cost-effectiveness. |

| Proper Storage | Dry completely and store in a moisture-free, protected environment. | Protects the electrode surface from degradation between uses. |

Achieve consistent and reliable electrochemical results with precision equipment from KINTEK.

Your experimental reproducibility depends on high-quality lab equipment and consumables. KINTEK specializes in providing durable electrodes and electrolytic cells designed for easy maintenance and long-term performance.

Let our expertise enhance your lab's efficiency and data accuracy.

Contact our specialists today for a consultation to find the perfect solutions for your laboratory's specific needs.

Visual Guide

Related Products

- Electrolytic Electrochemical Cell for Coating Evaluation

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Platinum Auxiliary Electrode for Laboratory Use

- Thin-Layer Spectral Electrolysis Electrochemical Cell

People Also Ask

- How does a three-electrode electrolytic cell function? Precision Testing for 8620 Steel in Corrosive Environments

- What are the advantages of a flat electrochemical cell for corrosion? Achieve Precise Pitting & Crevice Analysis

- What type of electrode system is the coating evaluation electrolytic cell designed for? Unlock Precise Coating Analysis

- What role does a water-jacketed electrolytic cell play in variable-temperature electrochemical corrosion measurements?

- How is a three-electrode electrochemical electrolytic cell utilized to evaluate Zr-Nb alloy corrosion resistance?