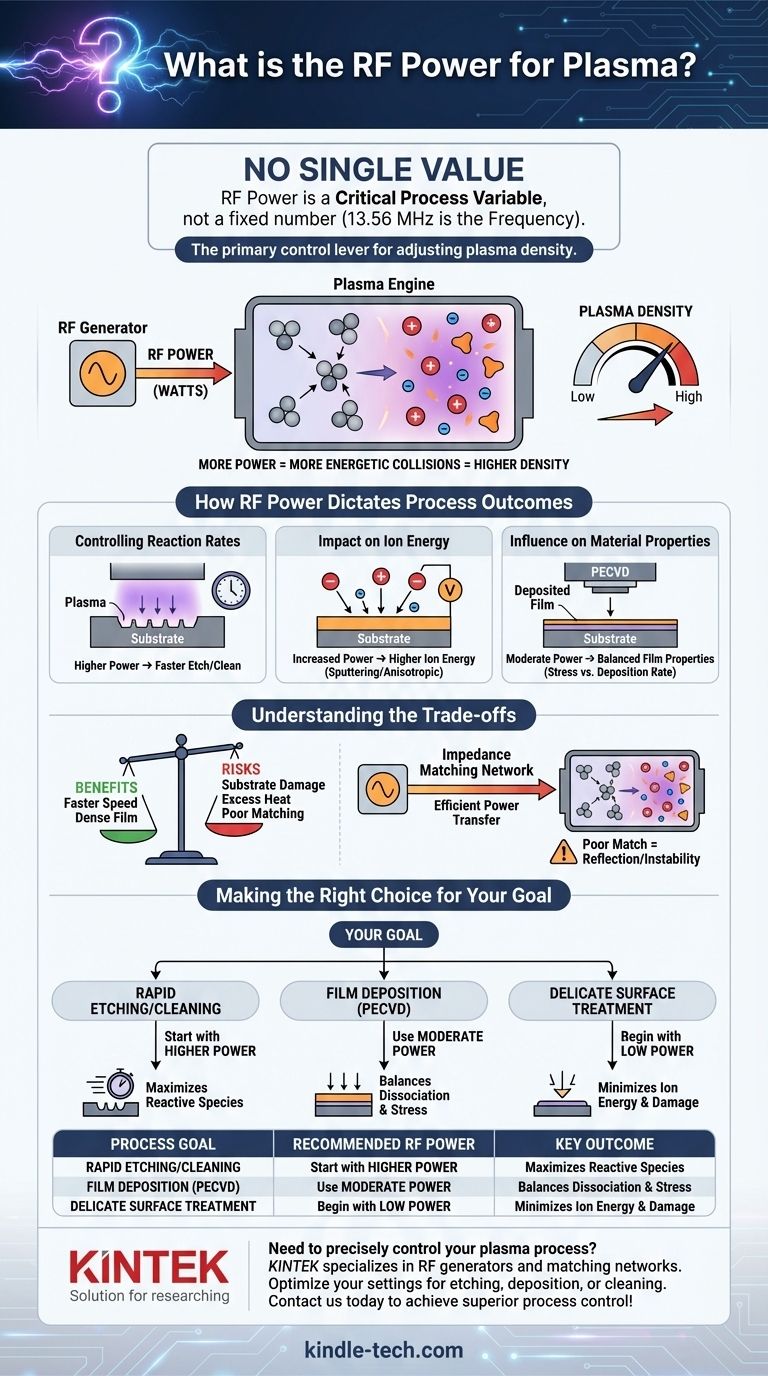

There is no single RF power value for creating a plasma. Instead, RF power is a critical process variable that is adjusted based on the specific application, chamber size, gas type, and desired outcome. The common 13.56 MHz figure refers to the radio frequency, an industry standard for efficient energy transfer, not the power level, which is measured in watts.

The core misunderstanding is to seek a single number for RF power. The reality is that RF power is the primary control lever for adjusting plasma density. Increasing power directly increases the number of ions and reactive species, which in turn dictates the speed and nature of your process, be it etching, deposition, or cleaning.

The Fundamental Role of RF Power

RF power is the engine of a plasma system. It provides the energy necessary to transform a neutral gas into an ionized, chemically reactive state. Understanding how it achieves this is key to controlling your process.

From Inert Gas to Reactive Plasma

An RF generator applies an alternating electric field to the process gas, typically at 13.56 MHz. This rapidly oscillating field energizes free electrons, causing them to collide with neutral gas molecules. These energetic collisions are the basis of plasma creation.

The Mechanism of Ionization

These collisions transfer energy to the gas molecules, leading to ionization (knocking an electron off, creating a positive ion and another free electron) and dissociation (breaking molecules into highly reactive atoms or radicals). The amount of RF power applied directly correlates to the rate and frequency of these collisions.

Power as a Control for Plasma Density

Simply put, more power means more energetic collisions. This creates a higher-density plasma, which is a plasma containing a greater concentration of ions, electrons, and reactive radicals per unit volume. This density is often the most critical factor determining the outcome of your process.

How RF Power Dictates Process Outcomes

Varying the RF power does not just create more plasma; it changes the plasma's fundamental characteristics. This allows you to tailor the process for specific results on a substrate.

Controlling Reaction Rates

For processes like plasma etching or surface cleaning, the rate of the reaction is paramount. A higher plasma density (achieved with higher RF power) provides more reactive species to interact with the substrate surface, resulting in a faster etch or cleaning rate.

Impact on Ion Energy

Increasing RF power also typically increases the plasma's self-bias voltage. This directly affects the energy with which ions are accelerated toward the substrate. Higher ion energy can be beneficial for applications requiring physical sputtering or highly directional (anisotropic) etching.

Influence on Material Properties

In plasma-enhanced chemical vapor deposition (PECVD), RF power influences the final properties of the deposited film. Too much power can lead to high film stress or damage from ion bombardment, while too little may result in a slow deposition rate or a less dense film.

Understanding the Trade-offs

Simply maximizing RF power is rarely the correct approach. It is a parameter that must be balanced against other variables and potential negative consequences.

The Risk of Substrate Damage

Excessive RF power can lead to significant ion bombardment, causing physical damage (sputtering) to the substrate or delicate device structures. It can also generate excess heat, which may be detrimental to temperature-sensitive materials.

The Interplay with Gas Pressure

RF power and process gas pressure are inextricably linked. A high-power plasma at low pressure behaves very differently from a high-power plasma at high pressure. The former is characterized by high-energy ions, while the latter has more chemical radicals due to increased collisions.

Power Delivery vs. Power Setting

The power you set on the generator is not always the power delivered to the plasma. An efficient impedance matching network is critical to ensure maximum power transfer from the generator to the chamber. A poor match means much of the power is reflected back, leading to an inefficient and unstable process.

Making the Right Choice for Your Goal

The optimal RF power is defined entirely by your process goal. Your starting point should be determined by the trade-off between speed, selectivity, and potential for damage.

- If your primary focus is rapid material removal (e.g., aggressive etching): Begin with higher power settings to maximize the density of reactive species and achieve faster rates.

- If your primary focus is depositing a high-quality, dense film (e.g., PECVD): Use a moderate power level to provide enough dissociation for the precursor gas without causing excessive film stress or damage from ion bombardment.

- If your primary focus is delicate surface modification or treating sensitive substrates: Start with low power to minimize ion energy and prevent physical or thermal damage to your material.

Ultimately, RF power is the most direct tool you have to control the fundamental character of your plasma and achieve your desired outcome.

Summary Table:

| Process Goal | Recommended RF Power Approach | Key Outcome |

|---|---|---|

| Rapid Etching/Cleaning | Start with higher power | Maximizes reactive species density for faster rates |

| Film Deposition (PECVD) | Use moderate power | Balances dissociation with minimal film stress/damage |

| Delicate Surface Treatment | Begin with low power | Minimizes ion energy to protect sensitive substrates |

Need to precisely control your plasma process? KINTEK specializes in lab equipment and consumables for plasma applications, including RF generators and matching networks. Our experts can help you optimize RF power settings for your specific etching, deposition, or cleaning needs, ensuring efficiency and protecting your substrates. Contact us today to discuss your laboratory requirements and achieve superior process control!

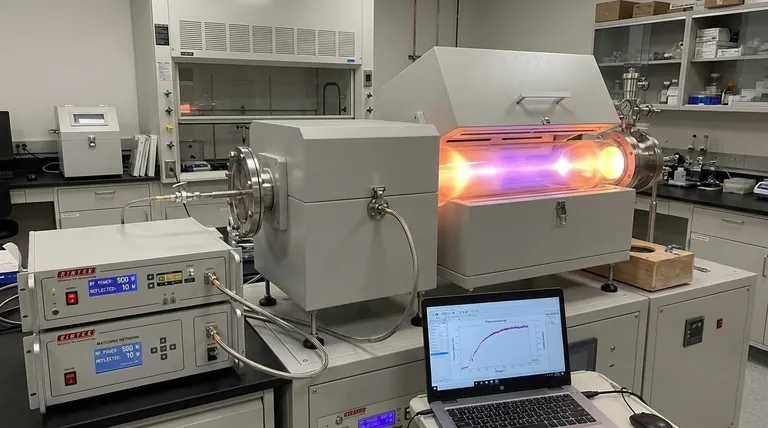

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What is the difference between CVD and PVD process? A Guide to Choosing the Right Coating Method

- What is the precursor gas in PECVD? The Key to Low-Temperature Thin Film Deposition

- What are the advantages of PECVD over CVD? Achieve High-Quality Thin Films at Lower Temperatures

- What is the difference between thermal CVD and PECVD? Choose the Right Thin-Film Deposition Method

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process