Sintering pressing force is the external pressure applied during manufacturing to compact powdered materials into a solid, dense object. This force works in conjunction with high heat to fuse the material’s particles together, creating a strong, finished part without melting the material itself. It is a critical parameter that directly influences the final properties of the component.

The core principle to understand is that applied pressure is not just for initial compaction. It acts as a powerful supplement to the natural, internal forces of sintering, enabling the creation of denser, stronger parts at lower temperatures and in less time.

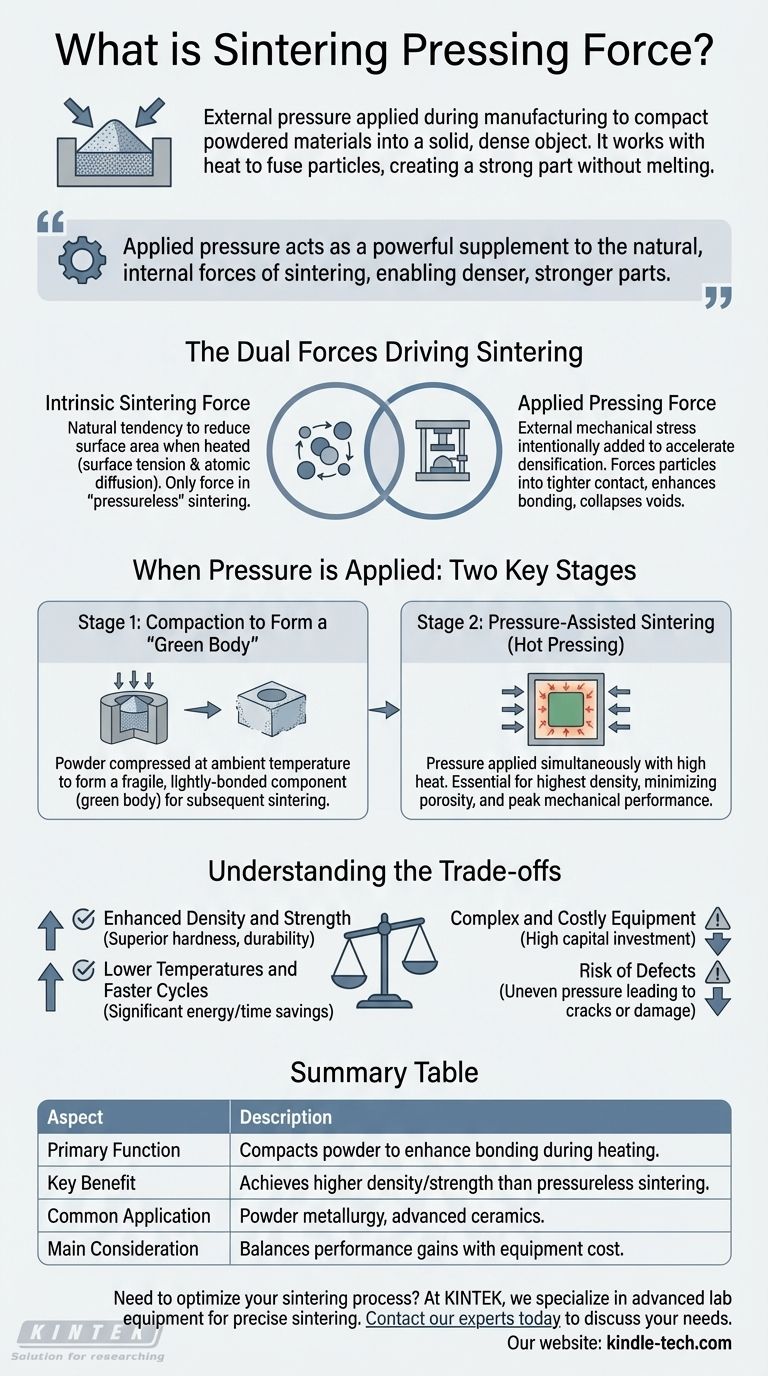

The Dual Forces Driving Sintering

The total force that drives the sintering process comes from two distinct sources. The effectiveness of the applied pressure depends entirely on its relationship to the material's natural sintering force.

The Intrinsic Sintering Force

Every powdered material has a natural tendency to reduce its surface area when heated. This phenomenon, driven by surface tension and atomic diffusion at the particle contact points, is the intrinsic sintering force.

In "pressureless" sintering, this is the only force at work, slowly pulling particles together and reducing the pores between them.

The Applied Pressing Force

The sintering pressing force is an external stress intentionally added to the system. This mechanical pressure dramatically accelerates the densification process.

By forcing particles into tighter contact, it enhances the rate of atomic bonding and helps collapse voids, resulting in a significantly denser and stronger final product.

When Pressure is Applied: Two Key Stages

Pressure isn't always applied in the same way or at the same time. The timing of its application defines two fundamentally different approaches in powder metallurgy and ceramics.

Stage 1: Compaction to Form a "Green Body"

The most common use of pressure is at the very beginning of the process. Powder is placed into a die or mold and compressed at ambient temperature.

This initial step forms a fragile, lightly-bonded component known as a "green body." This part is solid enough to be handled and moved to a furnace for the subsequent heating (sintering) stage.

Stage 2: Pressure-Assisted Sintering

In more advanced processes, pressure is applied simultaneously with high heat inside the furnace. This is known as pressure-assisted sintering or hot pressing.

This technique is used when the highest possible density and mechanical performance are required. The simultaneous application of heat and pressure is exceptionally effective at eliminating the final traces of porosity.

Understanding the Trade-offs

While applying a pressing force offers significant advantages, it also introduces complexities and potential challenges that must be managed.

Benefit: Enhanced Density and Strength

The primary reason to use a pressing force is to achieve higher relative density. Reducing porosity directly translates to a component with superior hardness, radial crushing strength, and overall durability.

Benefit: Lower Temperatures and Faster Cycles

Because the external pressure amplifies the sintering driving force, you can often achieve the target density at a lower temperature or in a shorter amount of time. This can lead to significant energy and time savings.

Challenge: Complex and Costly Equipment

Applying high pressure, especially at sintering temperatures, requires specialized and expensive equipment like hydraulic presses or Hot Isostatic Presses (HIP). This increases the capital investment compared to simple furnace sintering.

Challenge: Risk of Defects

Unevenly applied pressure can lead to density gradients, internal stresses, or even cracks in the final component. Likewise, excessive initial compaction force can damage the fragile green body before it ever reaches the furnace.

Making the Right Choice for Your Goal

The decision of when and how much pressure to apply depends entirely on the specifications of the final component.

- If your primary focus is cost-effective, high-volume production: A single compaction step to form a green body, followed by pressureless sintering, is the most common and economical approach.

- If your primary focus is maximum density and peak performance: Pressure-assisted sintering is necessary to minimize residual porosity and achieve superior material properties for demanding applications.

- If your primary focus is manufacturing complex shapes: You may need a carefully controlled initial compaction force to avoid damaging delicate features, which might require a more optimized heating cycle to reach the desired final density.

Ultimately, mastering the sintering pressing force is about transforming it from a simple compaction step into a precise tool for engineering material properties from the ground up.

Summary Table:

| Aspect | Description |

|---|---|

| Primary Function | Compacts powder particles to enhance bonding during heating. |

| Key Benefit | Achieves higher density and strength than pressureless sintering. |

| Common Application | Used in powder metallurgy and advanced ceramics manufacturing. |

| Main Consideration | Balances performance gains with equipment cost and complexity. |

Need to optimize your sintering process for superior part density and strength?

At KINTEK, we specialize in providing the advanced lab equipment and consumables necessary for precise sintering and hot pressing applications. Whether you are developing new materials or scaling up production, our expertise can help you select the right technology to achieve maximum performance and efficiency.

Contact our experts today to discuss your specific needs and discover how KINTEK's solutions can enhance your laboratory's capabilities.

Visual Guide

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

People Also Ask

- How big is the isostatic pressing market? A Deep Dive into the $1.2B+ Advanced Manufacturing Enabler

- How much does an isostatic press cost? A Guide to Lab vs. Industrial Pricing

- What is the difference between sintering and pressing? A Guide to Powder Metallurgy Processes

- What is the process of isostatic graphite? A Guide to High-Performance, Uniform Material Creation

- What is cold isostatic pressing examples? Achieve Uniform Density in Powder Compaction