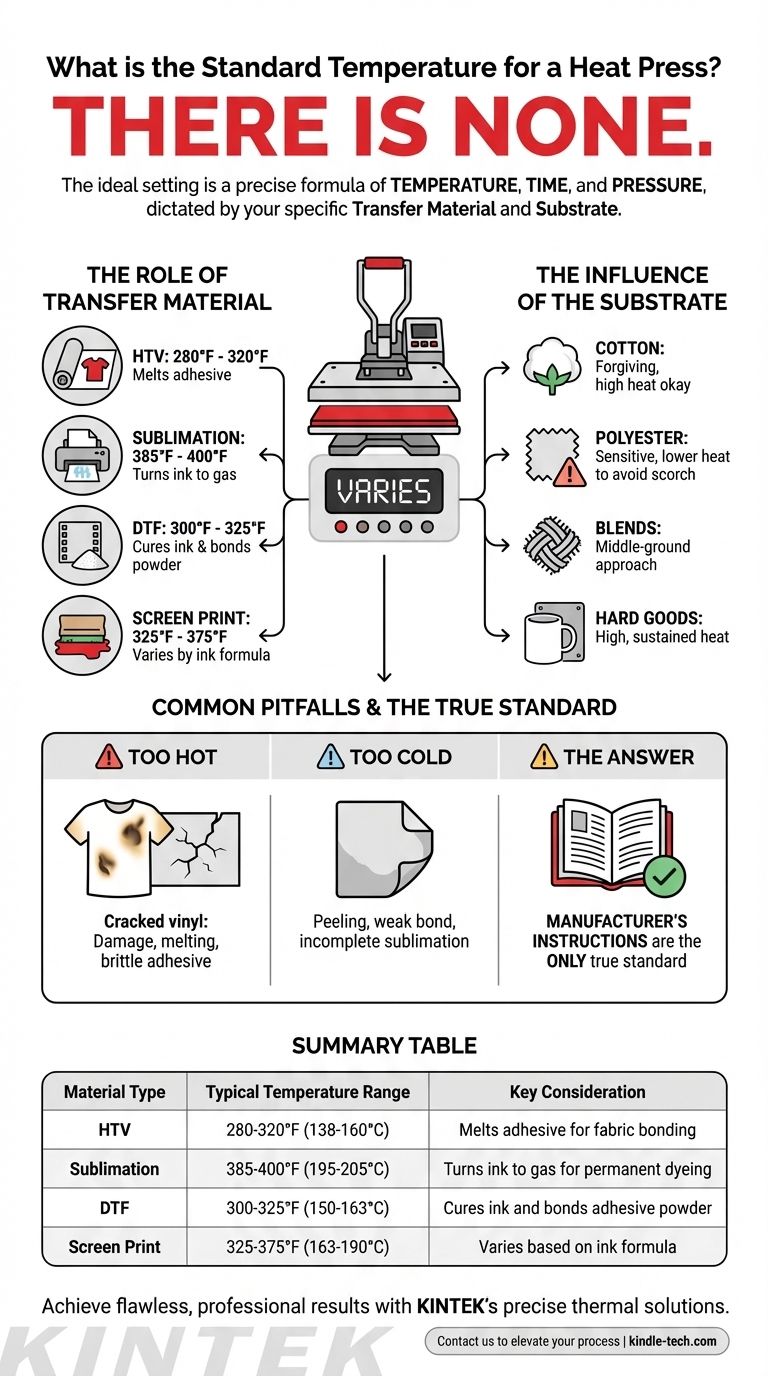

There is no single standard temperature for a heat press. While many common applications fall within the 305°F to 400°F (150°C to 205°C) range, the correct temperature is not a universal setting. It is dictated entirely by two factors: the type of transfer material you are using (like vinyl or sublimation ink) and the substrate you are pressing it onto (like a cotton shirt or a ceramic mug).

The most common mistake is searching for one "perfect" temperature. A successful, durable transfer is the result of a precise formula balancing temperature, time, and pressure. Your goal should be to find the specific formula recommended for your unique combination of materials.

Why "Standard Temperature" is a Misleading Concept

The idea of a single setting is appealing, but it ignores the fundamental science of how heat transfers work. Different materials require different levels of heat to activate adhesives or trigger chemical reactions.

The Role of the Transfer Material

Every type of transfer has a unique activation point. Using the wrong temperature will lead to failure.

- Heat Transfer Vinyl (HTV): Most standard HTV requires relatively lower temperatures, often between 280°F and 320°F (138°C - 160°C). The heat's job is simply to melt the adhesive backing so it bonds to the fabric.

- Sublimation Transfers: These require very high heat, typically 385°F to 400°F (195°C - 205°C). The temperature isn't melting glue; it's turning the solid ink into a gas (sublimation) so it can permanently dye the fibers of the material.

- Direct to Film (DTF) Transfers: These usually press in a mid-to-high range, around 300°F to 325°F (150°C - 163°C). The heat cures the ink and bonds a special adhesive powder to the garment.

- Screen Printed Transfers: The temperature for these varies widely based on the ink formula used by the printer, but they often fall in the 325°F to 375°F (163°C - 190°C) range.

The Influence of the Substrate

The material you are pressing onto is just as important as the transfer itself. It must be able to withstand the required heat without being damaged.

- 100% Cotton: A very forgiving material that can handle high heat, making it suitable for almost any type of transfer.

- 100% Polyester: This material is sensitive. High heat can scorch, melt, or cause "dye migration," where the fabric's dye bleeds into your transfer. Lower temperatures are critical.

- Blends (e.g., 50/50 Cotton/Poly): These require a middle-ground approach, balancing the needs of the transfer with the heat sensitivity of the polyester fibers.

- Hard Goods (Mugs, Tiles, Metal): These require high, sustained temperatures (often near 400°F) to allow the heat to fully penetrate the dense, non-porous surface.

Understanding the Trade-offs and Common Pitfalls

Focusing only on temperature while ignoring time and pressure is the root cause of most failed projects.

The Danger of "Too Hot"

Setting the temperature too high can cause irreversible damage. You risk scorching the fabric, melting delicate materials like polyester, or burning the adhesive on vinyl, which makes it brittle and prone to cracking.

The Problem of "Too Cold"

An insufficient temperature is the primary cause of transfers peeling off, especially after washing. The adhesive on HTV won't melt properly, or the sublimation process won't fully complete, resulting in a weak or non-existent bond.

Ignoring the Manufacturer's Instructions

The company that made your vinyl, paper, or transfer has done the testing. Their recommended settings for temperature, time, and pressure are the true "standard" for that specific product. Ignoring them is a costly gamble.

Inconsistent Pressure and Cold Spots

Even with the right temperature, a poor-quality press with "cold spots" on its platen will produce uneven results. Likewise, incorrect pressure—too light or too heavy—can prevent a full bond from forming.

How to Find the Correct Settings for Your Project

Instead of searching for a standard, learn to identify the correct variables for your specific task.

- If your primary focus is applying standard HTV to cotton: Start with the manufacturer's guide, which is often around 305°F for 15 seconds with medium pressure, but always verify.

- If your primary focus is sublimation on polyester or mugs: You will need high heat, typically 400°F for 60 seconds on fabric or several minutes for mugs, to ensure the ink turns to gas properly.

- If your primary focus is pressing on heat-sensitive fabrics: Use the lowest possible temperature recommended by your transfer manufacturer and protect the garment with a Teflon sheet or parchment paper.

- If you are ever unsure: Always default to the instructions provided by the manufacturer of your transfer material and perform a small test press on a scrap piece or hidden area first.

By understanding the relationship between your materials and the heat press settings, you gain the control needed to produce professional, durable results every time.

Summary Table:

| Material Type | Typical Temperature Range | Key Consideration |

|---|---|---|

| Heat Transfer Vinyl (HTV) | 280°F - 320°F (138°C - 160°C) | Melts adhesive for fabric bonding |

| Sublimation Transfers | 385°F - 400°F (195°C - 205°C) | Turns ink to gas for permanent dyeing |

| Direct to Film (DTF) | 300°F - 325°F (150°C - 163°C) | Cures ink and bonds adhesive powder |

| Screen Printed Transfers | 325°F - 375°F (163°C - 190°C) | Varies based on ink formula |

Achieve flawless, professional results with every press. KINTEK specializes in reliable lab equipment and consumables for precise thermal applications. Whether you're working with HTV, sublimation, or DTF transfers, our heat press solutions ensure consistent temperature control and even pressure distribution. Let our experts help you select the perfect equipment for your specific materials and substrates. Contact us today to discuss your needs and elevate your heat transfer process!

Visual Guide

Related Products

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Double Plate Heating Press Mold for Lab

- Automatic Laboratory Heat Press Machine

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What causes hydraulic pressure spikes? Prevent System Damage from Hydraulic Shock

- What does a hydraulic heat press do? Achieve Industrial-Scale, Consistent Pressure for High-Volume Production

- What is a heated hydraulic press used for? Essential Tool for Curing, Molding, and Laminating

- How is the pressure and temperature process used to make a synthetic diamond? Replicate Earth's Diamond Formation in a Lab

- What is a hot hydraulic press? Harness Heat and Pressure for Advanced Manufacturing