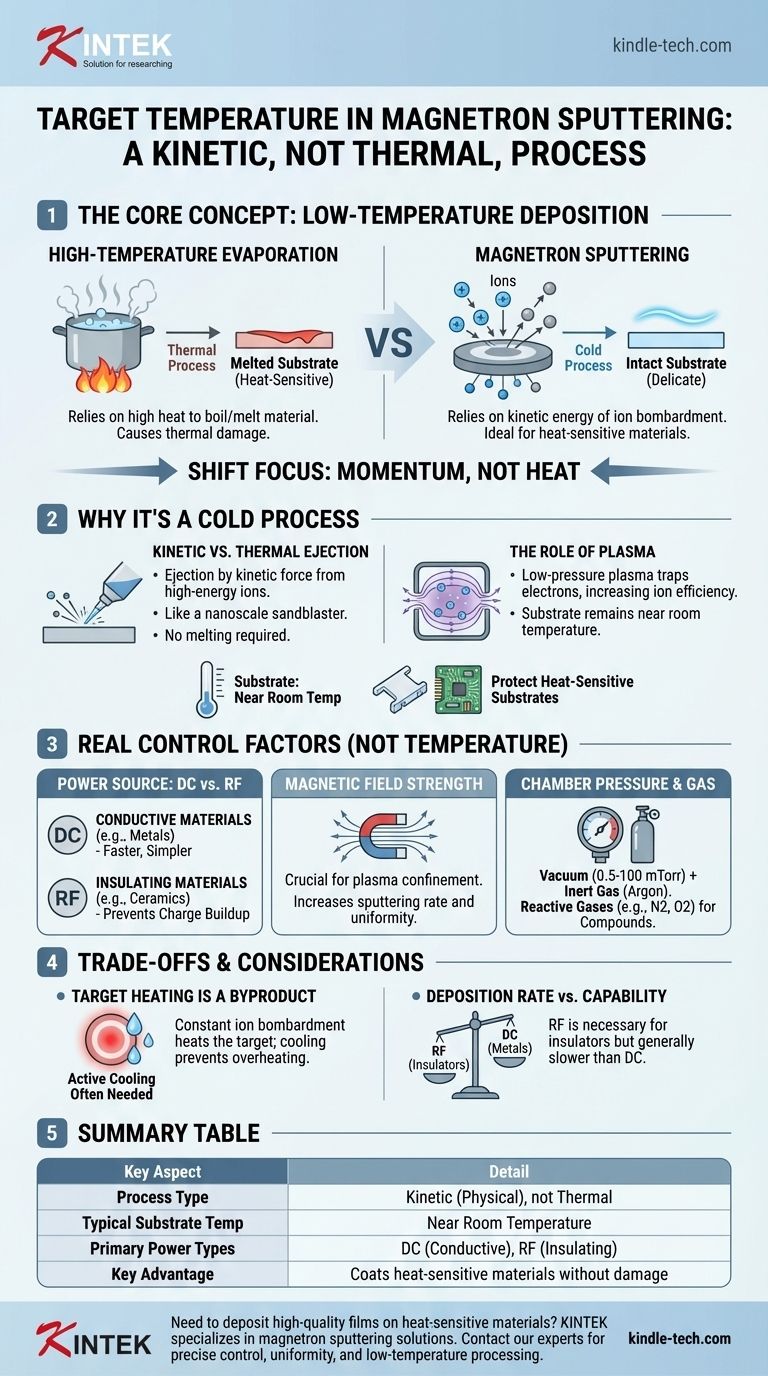

To be precise, magnetron sputtering does not operate at a single, universal "target temperature." Instead, it is fundamentally a low-temperature deposition technique, which is one of its most significant advantages. This characteristic allows it to coat heat-sensitive materials like plastics or electronics without causing the thermal damage associated with high-temperature evaporation methods.

The critical concept to grasp is that magnetron sputtering is a physical process, not a thermal one. Material is ejected from the target by the kinetic energy of ion bombardment, not by melting or evaporation. This is why it's considered a "cold" process, making it ideal for coating delicate, heat-sensitive substrates.

Why Sputtering is a Low-Temperature Process

To understand the role of temperature, we must first understand the core mechanism of sputtering. The process is governed by momentum transfer, not heat.

Kinetic vs. Thermal Ejection

In thermal processes like evaporation, a material is heated until its atoms boil off. This requires extremely high temperatures.

Magnetron sputtering works like a nanoscale sandblaster. High-energy ions from a plasma are accelerated into the target material, physically knocking atoms loose with kinetic force.

While this bombardment generates some localized heat on the target surface, the overall process does not rely on high ambient temperatures to function.

The Role of the Plasma

The sputtering process occurs within a low-pressure plasma. A strong magnetic field traps electrons near the target, dramatically increasing the efficiency of ion creation.

These high-energy ions are what do the work. The substrate being coated, however, can remain at or near room temperature.

Protecting Heat-Sensitive Substrates

This low-temperature environment is a key industrial advantage. It allows for the deposition of durable, high-purity metallic or ceramic films onto materials that would melt, warp, or be destroyed by other methods.

What Factors Actually Control the Process?

If temperature isn't the primary control variable, your focus should be on the parameters that directly influence deposition rate, film quality, and uniformity.

Power Source: DC vs. RF

The type of power supply is a fundamental choice.

DC (Direct Current) sputtering is simpler, faster, and more cost-effective. It is used exclusively for electrically conductive target materials, like pure metals.

RF (Radio Frequency) sputtering uses an AC power source to prevent charge buildup. This makes it essential for sputtering electrically insulating (dielectric) materials, such as ceramics.

Magnetic Field Strength

As noted in system design, the magnetic field strength is crucial. A stronger, well-designed magnetic field confines the plasma more effectively near the target.

This directly increases the sputtering rate and helps ensure the target erodes evenly, which improves the uniformity of the final coating.

Chamber Pressure and Gas

The process occurs in a vacuum chamber backfilled with a small amount of an inert gas, typically Argon.

The chamber pressure (from 0.5 to 100 mTorr) affects the energy of the ions and how the sputtered atoms travel to the substrate. Adding reactive gases like nitrogen or oxygen allows for the creation of compound films like nitrides or oxides.

Understanding the Trade-offs and Considerations

While it is a low-temperature process, there are still thermal considerations and other limitations to keep in mind.

Target Heating Can Still Occur

The constant, high-energy ion bombardment does heat the target material itself. In high-power applications, the target often requires active water cooling to prevent it from overheating, cracking, or melting.

The key distinction is that this is a byproduct of the process, not the driving mechanism.

Deposition Rates

There is a trade-off between material capability and speed. RF sputtering, while necessary for insulators, generally has a lower deposition rate than the more efficient DC sputtering process for metals.

Cost and Complexity

DC sputtering systems are typically simpler and less expensive. The RF power supplies and matching networks required for insulating materials add significant cost and complexity to the system, making RF sputtering better suited for applications where it is the only viable option.

Making the Right Choice for Your Application

The "temperature" is a consequence of the process, not a setting. Your focus should be on matching the sputtering technique to your material and goal.

- If your primary focus is high-speed coating of conductive metals: DC magnetron sputtering is the most efficient and cost-effective choice.

- If your primary focus is coating insulating materials (like ceramics or glass): RF magnetron sputtering is the required method to avoid electrical charge buildup on the target.

- If your primary focus is protecting a heat-sensitive substrate (like a polymer): The inherently low-temperature nature of magnetron sputtering makes it an excellent candidate.

- If your primary focus is creating a precise alloy or compound film: Co-sputtering from multiple targets or introducing reactive gases gives you precise control over the film's composition.

Ultimately, understanding that sputtering is governed by kinetic energy, not high heat, is the key to leveraging its remarkable versatility.

Summary Table:

| Key Aspect | Detail |

|---|---|

| Process Type | Kinetic (Physical), not Thermal |

| Typical Substrate Temperature | Near Room Temperature |

| Primary Power Types | DC (for conductive materials), RF (for insulating materials) |

| Key Advantage | Coats heat-sensitive materials without thermal damage |

Need to deposit high-quality films on heat-sensitive materials? KINTEK specializes in lab equipment and consumables, offering magnetron sputtering solutions that provide precise control, excellent film uniformity, and the low-temperature processing essential for delicate substrates like polymers and electronics. Contact our experts today to find the ideal sputtering system for your laboratory's unique application and material requirements.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Evaporation Boat for Organic Matter

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- What are the methods of graphene synthesis? Choose the Right Path for Your Application

- Which of the following are properties of carbon nanotubes? Unlock Their Unique Electrical, Thermal & Mechanical Strengths

- What is the best substrate for graphene? It depends on your application's specific needs.

- Which material is used in thin film? Discover the Right Material for Your Application

- What is thin film technology examples? From Microchips to Solar Panels and Beyond

- Is deposition a chemical process? Understanding Chemical vs. Physical Thin-Film Methods

- What are the benefits of thin films? Unlock Enhanced Durability, Optics & Electronics

- What is the maximum thickness for thin film interference? It Depends on Your Light Source's Coherence